The Ministry of Railways identified k178 + 910 quality accident as a major quality accident of railway construction project, k158 + 300 and k106 + 300 quality accidents as general quality accidents of railway construction project.

The drainage system is not in place, perfect and unblocked, resulting in the subgrade and culvert often soaked in water.

The subgrade subsidence in three places was serious, and the maximum subsidence reached 64.2cm, 16cm and 9.7cm respectively.

(2) the quality problems of subgrade retaining and drainage works are prominent.

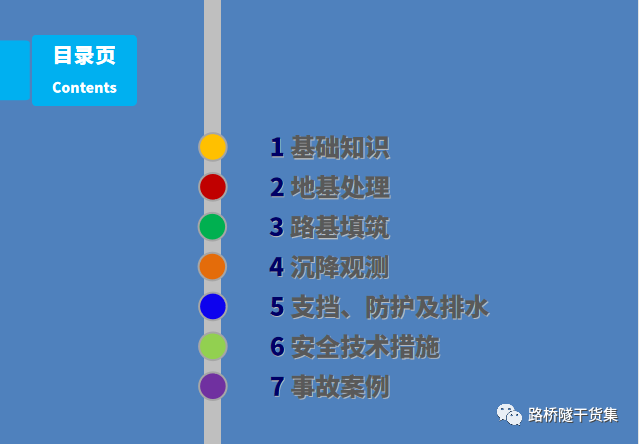

The article is used for learning and communication (because the length of the article is too long, it affects the impression, and the complete information is detailed in PPT) 01 basic knowledge.

The over excavated part shall be filled with qualified replacement materials.

(3) for the cushion with geotechnical materials in the middle, the upper cushion shall be paved manually.

When the drill moves, the support foot shall not be pressed to the pile position..

(2) the small excavator shall dig in place at one time.

(5) static load test of pile foundation, (6) conclusion of test pile shall timely summarize the pile test conclusion according to the pile test results, draw the number and combination of machinery and personnel, and put forward the number of machinery required for large-scale construction in the next step, technical parameters adopted in construction, key points of safety and quality control, etc.

2.3 key points of replacement and filling control: ⑴ when the bottom fluctuates greatly, steps or gentle slopes can be set, and the replacement and filling construction shall be carried out in the order of first deep and then shallow.

The filler is not strictly controlled, the particle size exceeds the standard, the grading is poor, and even some filler categories are inconsistent with the design; The filling does not pay attention to process control, barbaric operation, and the virtual paving thickness exceeds the standard; The subgrade section is not widened enough, the slope is not compacted, and the scouring is serious in rainy season; The step width of transition section is insufficient, and both sides of culvert are filled asymmetrically; The laying of geogrid is not smooth, the overlapping length of joints is not enough, the overlapping treatment is not standardized, etc.

02 foundation treatment 2.1 common methods of foundation treatment common methods of foundation treatment: 2.2 pile test purpose: pile test is to provide technical basis for the next soft foundation treatment project construction, including: applicability of main equipment, model and quantity of supporting equipment; The rationality of the construction process and construction sequence shall be preliminarily selected according to the geological conditions, and the allocation and running in of relevant personnel shall be carried out by determining the construction control parameters and process time; Whether the pile quality, bearing capacity of single pile or foundation after treatment meet the design requirements, etc.

Common construction process flow construction steps of vibration sinking pipe pouring construction steps of pump pressure mixture pouring in long spiral drilling pipe during pouring and pulling out, pay attention to the following points: pile connection and pile supplement.

The pile diameter of the pile connection part shall be 20cm larger than the design pile diameter, and the biting length with the existing pile shall not be less than 20cm.

Prevention measures: the upper cushion shall be paved manually and compacted by light compaction subgrade.

The bottom layer to be replaced temporarily or overnight shall be covered with common quality problems of thermal insulation materials and prevention measures: ⑴ the depth of replacement does not meet the design requirements.

2.4 gravel cushion construction: key control points: ⑴ before large-scale construction, conduct compaction process test, determine construction parameters and report to the supervisor for approval.

(2) transverse road camber shall be made for the base after surface cleaning and compaction.

(7) Annex ① raw material test report (copy); ② Various original records, process records, etc; ③ Static load test.

Common quality problems and prevention measures: ⑴ sand and stone materials do not meet the requirements.

(3) if the bottom groove to be replaced in winter is frozen, the frozen layer shall be removed before replacement.

(2) geotechnical materials are damaged.

Prevention and control measures: the oversized particles shall not be loaded in the stockyard, and a small amount shall be picked up or broken manually after arriving at the site; Aggregate shall be remixed manually at any time.

Verify that the construction technology and construction organization can achieve the expected quality and progress effect, the allocation of mechanical equipment and personnel is reasonable, and the construction efficiency can meet the construction period determined by the construction organization.

Control points: common quality problems: prevention measures: ⑴ one machine and one person shall be on-site to check the deviation of pile position and the verticality of drill pipe, control the drilling depth and concrete pouring speed, and make on-site records to ensure the timely and uninterrupted supply of concrete.

(5) the compaction quality cannot meet the requirements of design and standard inspection.

The light roller shall be used for compaction to ensure that the geotechnical materials are intact.

The filling layer is thick, the roller runs faster, the surface flatness is poor, and the water content deviates from the optimal water content.

Main contents of construction summary of test section: ⑴ project overview this part mainly includes project overview, design pile foundation parameters and geological conditions, with emphasis on design pile foundation parameters and geological conditions.

The accident resulted in the delayed operation of multiple EMUs at the speed limit, which seriously affected the normal railway transportation order and endangered the safety of train operation.

The slope of road camber shall not be slower than the designed slope, which is conducive to drainage.

The material of sand and gravel shall meet the requirements of design and standard inspection, especially the mud content shall not exceed the standard, otherwise it is easy to cause consolidation and can not play the role of drainage.

After the paving of geotechnical materials, the cushion of the upper layer shall not directly contact with large machinery, otherwise it is easy to cause damage to the geogrid, which is unfavorable to the vertical and horizontal force transmission.

From July 7 to 8, 2009, a subgrade subsidence accident occurred in a “passenger dedicated line”.

This part mainly includes the purpose, location and work content of pile test.

The original cause analysis given by the Ministry of Railways: ⑴ subgrade filling is not standardized.

(4) during the replacement of group A and B fillers, the maximum particle size exceeds the standard, and large or small particles gather in pits during construction.

The dump truck shall not drive directly onto the geotechnical materials.

For example, start construction without process test; In case of discrepancy between actual geology and survey data, it is not changed in time, which will affect the treatment effect; Weak process control means for construction quality, etc.

(3) the water content of lime soil replacement is large, the lime content is insufficient, the mixing is uneven, and the soil particles in lime soil are large.

(3) personnel and machinery during the construction of test pile.

(2) the replacement filler shall be laid and compacted in layers, and the mass density of the compacted dry soil shall be measured by sampling inspection.

The settlement joint and inverted filter layer are not constructed according to the design requirements; Excessive amount of rubble in rubble concrete; The construction of prestressed slope anchor cable is not in place, there are some problems such as insufficient length and quantity of anchor cable, no rust prevention treatment, and even some anchor cables are used without tensioning.

(2) purpose, location and test content of pile test.

Prevention and control measures: strictly control the closing of materials, and unqualified materials shall not enter the site.

⑶ there are many quality hidden dangers in CFG pile and karst grouting construction.

(4) description of construction process, records of various mechanical parameters, geological conditions and other process records, etc.

Prevention and control measures: strictly guide the construction according to the results of the test section, and strengthen the control of raw materials.

When the elevation of the top surface of CFG pile is lower than the design elevation of the bottom surface of pile head after chiseling off the pile head or due to shallow pile breaking within 1.5m, The pile shall be connected with the mixture with the same mix proportion as the pile material or one level higher than the pile body.

2.5 the main construction machinery and equipment of cement fly ash gravel pile (CFG pile) shall be reasonably configured in combination with the construction scheme, machinery, personnel combination and construction period requirements determined by the test pile; The construction of CFG piles requires the configuration of long auger or vibrating immersed pile driver, generator (if used for self power generation), concrete delivery pump, loader, dump truck, excavator, small excavator, concrete tanker, etc.

(3) the compaction quality cannot meet the design and standard inspection requirements, especially the compaction of the upper cushion, which is generally only 20cm thick, and the geogrid is below, so the vibration is not easy to be too large, otherwise it is easy to cause damage to the geogrid; The gravel cushion is generally mixed with an appropriate amount of fine particles (such as stone powder), otherwise it is difficult to compact and it is difficult to ensure the compactness of the cushion.

Prevention and control measures: the lime content shall be controlled within the range of – 0.5% ~ + 1.0% of the test mix proportion, and the chemically improved mixing soil shall be broken when it is maintained at ± 2% of the optimal water content.

(2) large area excavation for replacement and filling, and poor drainage in rainy season, resulting in rainwater immersion.

During the construction of test pile, the allocation of on-site technical director, technician, safety and quality director, test director, operator and workers.

Prevention measures: first excavate the drainage ditch, unblock the drainage system, and often send someone to dredge the drainage ditch.