When manually adjusting the direction or position of the laminate, the crowbar cannot be operated directly.

In the process of pouring concrete, it can be well completed by automobile pump.

The seam is usually 5mm, and 8mm foam strip should be prepared.

The elevation is controlled by the adjustable support under the plate.

Cantilever construction can be carried out on the floor without prefabricated components, and prefabricated bolts can be fixed in cast-in-situ concrete.

The installation and positioning of laminated plates is a difficulty in engineering construction, because it is difficult to insert the anchor reinforcement head into the center line of the beam, and it is easy to damage the installed beam reinforcement.

The temporary support of the laminated plate can be removed only after the strength of the post cast concrete meets the design requirements.

Short span reinforcement shall be set under long-span reinforcement.

If there is any problem with the height, corresponding measures shall be taken in time for effective adjustment.

In this method, the socket plate method is used for construction, the spacing is 120cm, and the jacking height is adjusted by the jacking adjustable method.

2.

Therefore, it is necessary to make a tripod to fix the pole.

After the concrete pouring is completed, it shall be removed and transported to the next construction site.

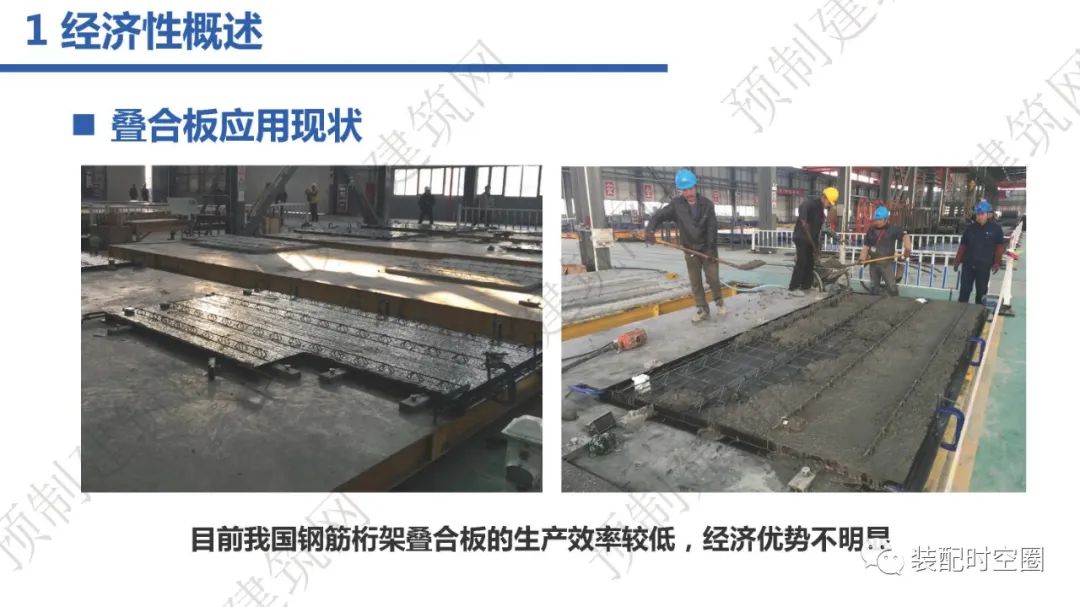

As one of the most commonly used technologies in prefabricated building structures in China, the rational application of this technology can not only optimize the construction environment of the previous construction site, but also avoid the common quality problems in the previous construction to a certain extent.

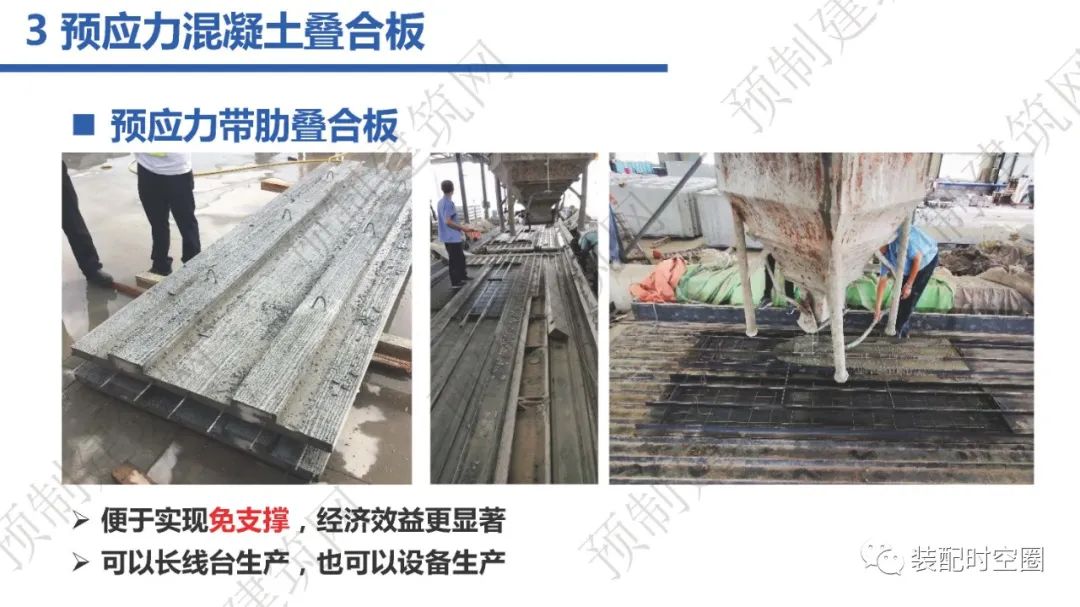

■ the economy of composite floor slab is the key factor determining the development of prefabricated building, building industrialization and the survival of precast concrete industry; ■ there will be more and more EPC projects, and the construction, general contractor and all relevant parties should actively think and target; ■ all kinds of prestressed concrete composite slabs have broad development space, which is worthy of in-depth research and engineering promotion.

3.

6 slab joint treatment in order to solve the problem of missing and dislocation of reinforcement at the joint of composite slab, the method of blocking slab joint is adopted when pouring concrete.

Installation and adjustment of laminated plate the laminated plate shall be installed vertically from top to bottom, placed 30cm above the installation surface and stopped.

In order to control the height error within 5mm, if it is found that the flatness does not meet the requirements after installing the composite plate, the concrete cannot be poured on the upper part.

Cast in situ concrete construction of upper layer of prefabricated components First, the loading and unloading platform.

The construction period of the project can be greatly shortened by using the laminated plate construction technology.

The second is the aluminum film support system.

For reinforcement binding, the working face of laminated plate shall be cleaned first, and then the reinforcement shall be bound.

There are two main support methods.

Wooden blocks shall be installed on the main keel with a spacing of 200mm.

If you want to add a rod under the laminate, you must add the rod before the precast component is installed.

The construction personnel shall adjust the direction of the laminated plate and align the side line of the laminated plate with the installation position of the wall.

The high-rise part is poured by vehicle mounted pump.

In addition, at the connection of laminated plates, the reinforcement shall be bound in strict accordance with the contents of the design drawings, and the reinforcement can be carried out in strict accordance with the corresponding distance.

Since the tripod only plays a temporary role, it must be able to provide three sets of support systems respectively.

The binding position shall be determined according to the design reinforcement spacing.

5.

Lay waste wood strips around the secondary keel, and use sponge strips at the joints to prevent mud leakage.

The laying process of composite plate shall be stable, slow, uniform and light, so as to avoid large impact caused by too fast, too fierce, plate surface fracture or crack.

The elevation of beam side formwork and shear wall side formwork shall be consistent with the elevation of slab bottom, and the construction deviation shall be controlled within the allowable error range.

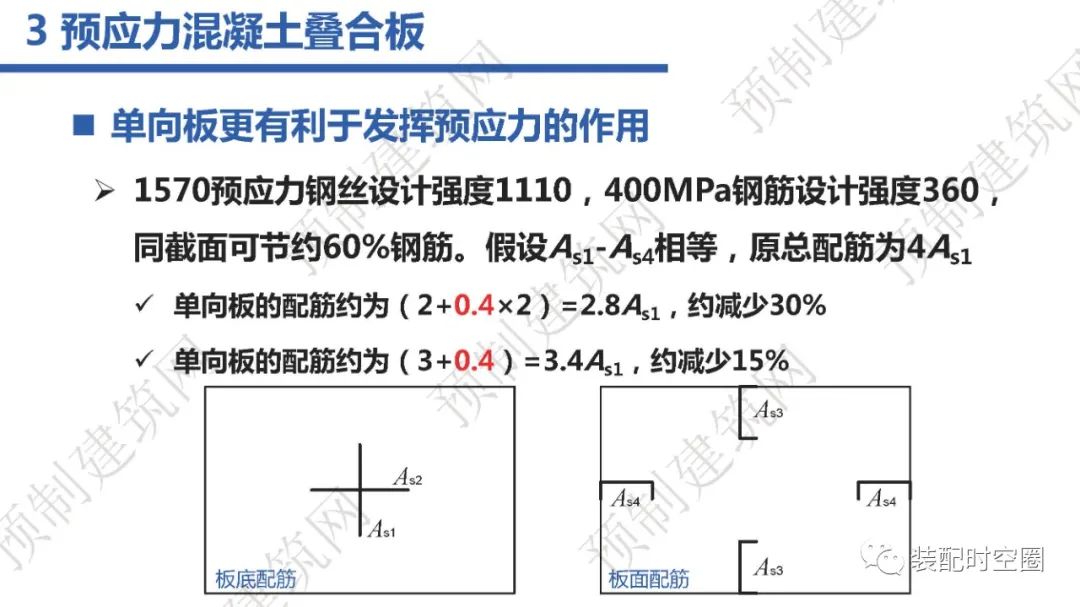

In addition, attention shall be paid to the arrangement of two-way slab reinforcement to ensure that the diameter and spacing of two-way slab reinforcement meet the design requirements; When the diameter and spacing of two-way slab reinforcement are inconsistent, place large reinforcement two-way slab under small reinforcement.

The laminate needs to be protected first, such as small wooden blocks to protect the edges and corners of the laminate.

First, wooden formwork support.

The installation and positioning accuracy of laminated plates shall be strictly controlled.

The top of the beam side formwork is the plate beam connection point.

Check the elevation after installation.

Before construction, the longitudinal reinforcement under the beam can be bound first, and then the beam can be bound after installing the laminate to avoid the impact of reinforcement fatigue on its strength.

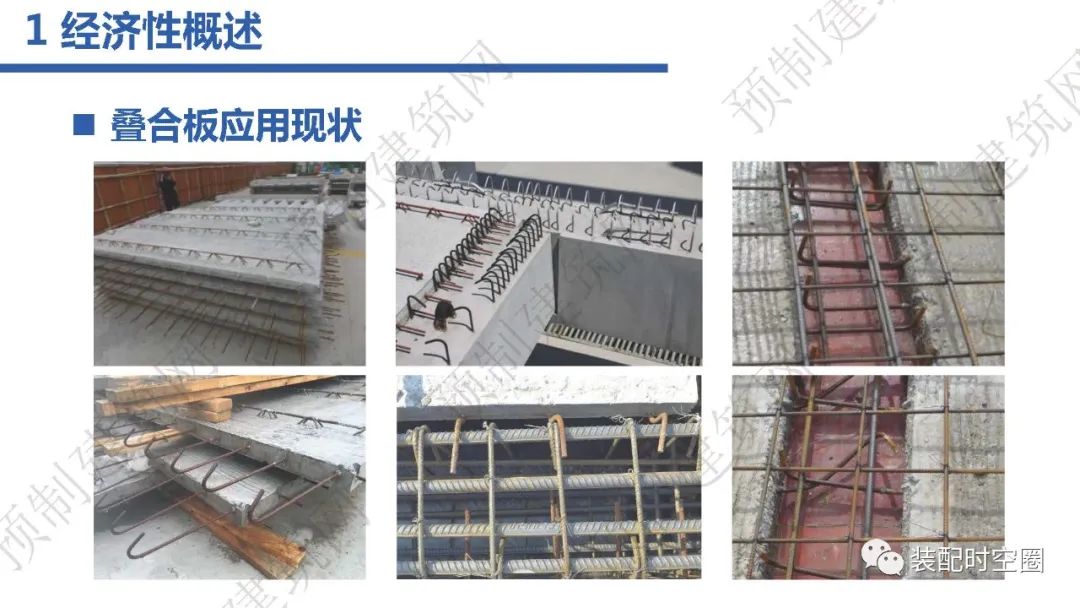

The stacking height shall not exceed three layers.

8 after the quality control composite board is transported to the site, it must be placed on the prepared site and managed by a specially assigned person.

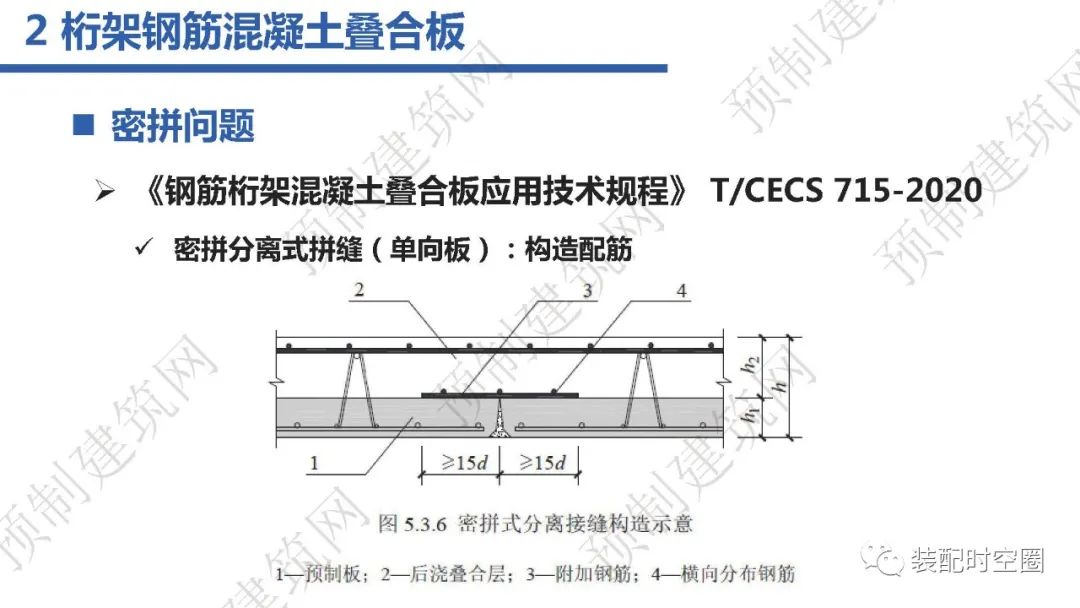

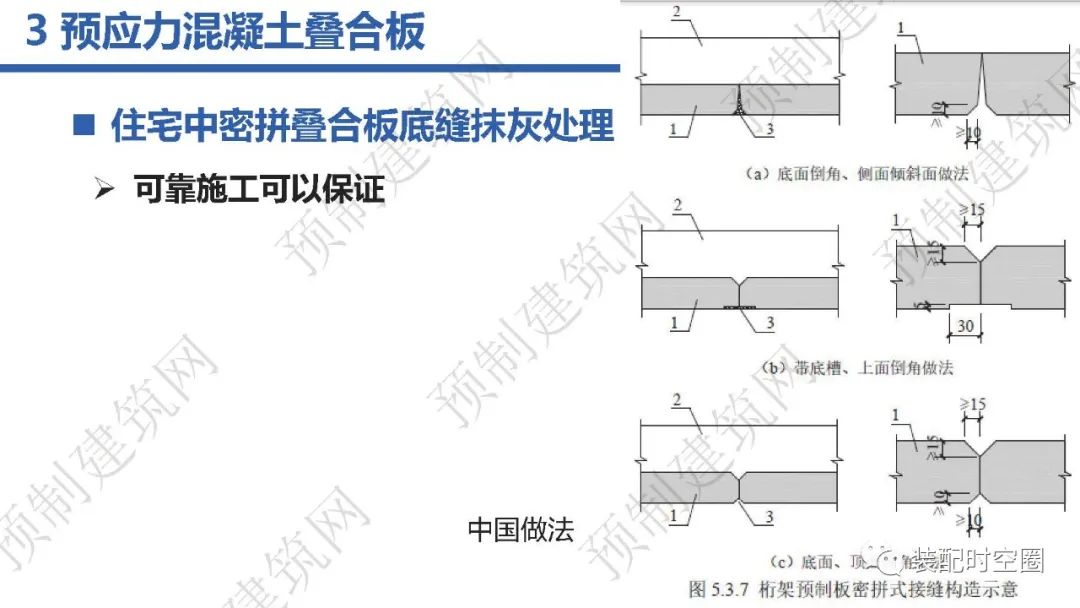

Fill the seam with foam strips and then sew with mortar.

After the installation of laminates, relevant personnel shall measure the elevation in time.

Check the elevation of the slab surface, the flatness of the support surface and the roughness of the joint surface to ensure that the construction deviation is within the allowable range of the specification; The construction load shall meet the design requirements to avoid concentrating large load on a single laminated plate; Strictly supervise the construction, and the construction personnel shall not carry out illegal operations such as cutting and opening on the precast slab; The gap between the laminated plates shall meet the design requirements; After hoisting, a specially assigned person shall be arranged to check the height difference of the joint at the bottom of the slab.

If the height difference of the joint at the bottom of the laminated floor slab cannot meet the design requirements, the components shall be hoisted again, and the height difference shall be adjusted by using the adjustable bracket.

At the beginning, the distributor must be designed in the cast-in-situ structure in order to clarify the specific location of the floor distributor.

The actual thickness of the laminated plate after pouring and forming is calculated by measuring the thickness of the prefabricated bottom plate and the height from the top of the prefabricated bottom plate to the reinforcement epithelium on site..

During pouring, the thickness shall be controlled and the layout height shall be clear to avoid slurry leakage when the elevation of the next laminate does not meet the requirements.

When manually adjusting the direction, pay attention that the reserved reinforcement on the laminated plate shall not collide with the wall reinforcement.

For example, in the actual construction of prefabricated building structures, the use of prefabricated laminated plates can effectively reduce the construction of formwork, support and other projects on the construction site, so as to reduce this part of expenditure; Third, compared with the traditional concrete pouring and reinforcement binding construction, the construction process of laminated plate in fabricated building structure is relatively simple, which is not easy to cause quality problems due to the technical problems of constructors in construction, so as to ensure the effect of project construction; Finally, the construction technology of the middle-level plywood of the fabricated building structure is relatively less affected by the changes of external environmental factors, and can be carried out under different construction environment backgrounds, so as to meet the different needs of subsequent construction and construction.

When designing drawings, it must be ensured that the distance between poles is not greater than 180cm.

In the construction of composite floor slab, the thickness of floor slab is 70mm, so embedding in this structure should be avoided as far as possible.

All climbing frames are embedded in the cast-in-situ structural wall with lifting scaffold.

The allowable deviation of the paving length of the composite plate is less than 5mm.

In order to solve the problem of slurry leakage during concrete pouring, double-sided adhesive tape is pasted on the edge of the beam.

When removing the prefabricated components of the support, it is the same as the cast-in-situ structure.

Beam, shear wall and floor concrete shall be poured at the same time.

After the hoisting and adjustment, the joints shall be filled, and the slab joints shall be filled with high-strength mortar to prevent slurry leakage and pollution during concrete pouring.

In addition, bending shall be prohibited during the construction of longitudinal reinforcement.

During the design of Aluminum Laminates, keels shall be designed in the laminate area to support the laminates.

When there is no reasonable cast-in-situ floor in the floor, the distributor base shall be designed as cast-in-situ floor.

4 after the reinforcement binding of the composite beam is completed, in order to facilitate the insertion of the anchor reinforcement of the composite plate into the beam, the beam side formwork shall be opened, the negative moment reinforcement shall be bound, and then the concrete shall be poured to form an integral with the composite layer.

Secondly, select distributors.

The pole shall be added in the middle where the distance between poles is too large.

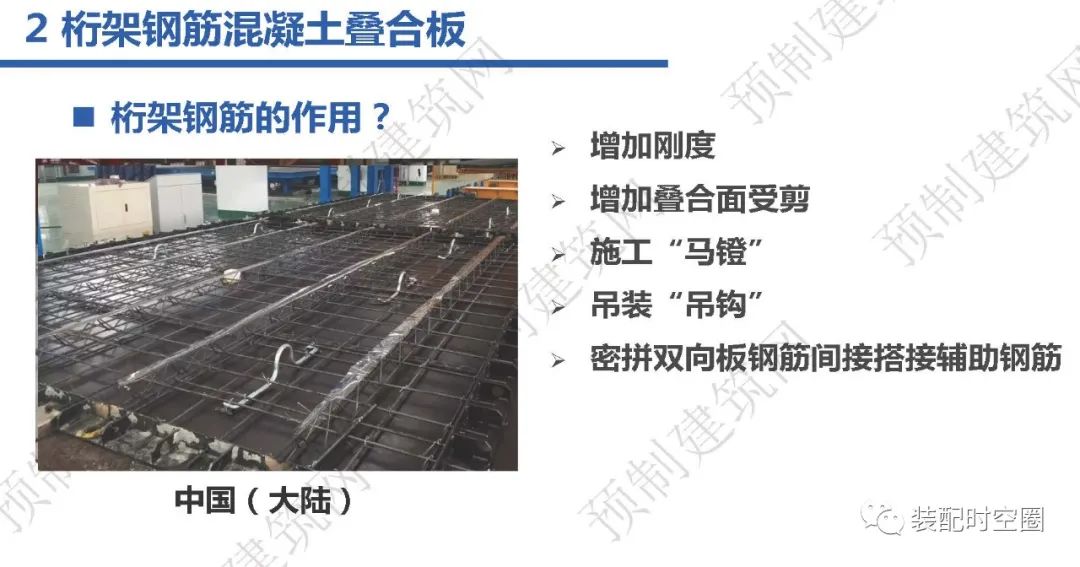

Since the reinforcement binding needs to pass through the truss on the laminated plate, confirm that the direction of the reinforcement hook is correct.

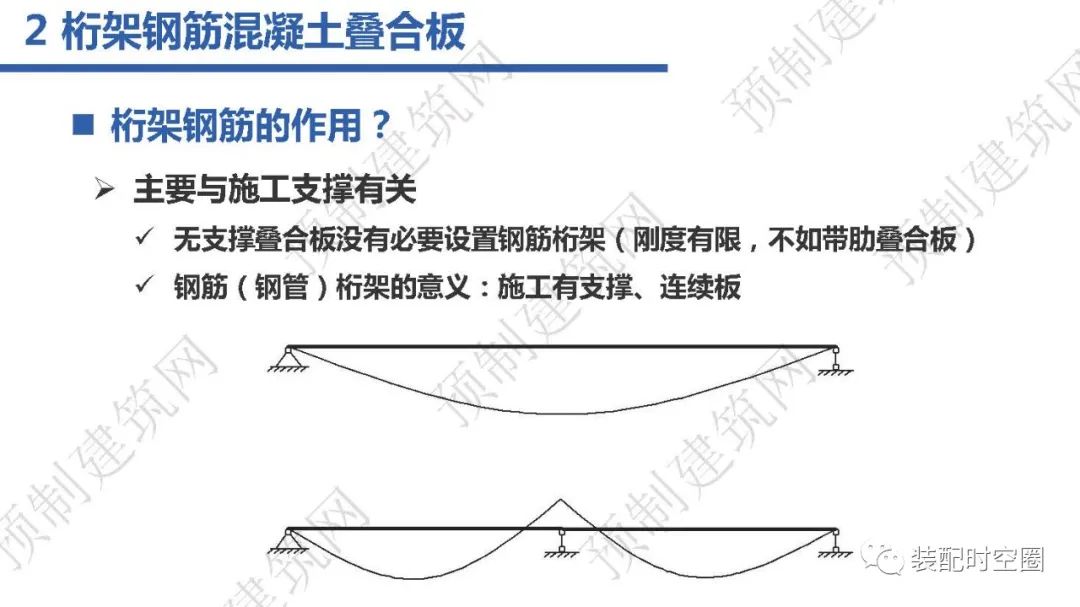

Based on the above advantages, it can be found that in the actual construction of prefabricated building structures in China, the application of laminated plate construction technology has become an inevitable trend of building development in the future, and more and more engineering projects have applied this technology Design of technical 1 support system for laminated slab construction in prefabricated building structure before the construction of composite slab, vertical rod support should be designed.

7.

In case of bad weather, color strips shall be added on the surface of the laminate, and the color strips must be installed within three days.

Especially in the construction of fabricated building structure, most of the laminated plates have completed the construction of foundation works in the factory, so there is no need to treat the laminated plates twice at the construction site, which effectively shortens the construction period of the project; Secondly, the application of laminate construction technology can greatly reduce unnecessary costs in construction.