Three specimens are randomly selected from each acceptance batch for unidirectional tensile test.

The tensile test piece of the joint is 600mm long, and the joint shall be located in the middle of the test piece.

Copyright statement: the copyright belongs to the original author.

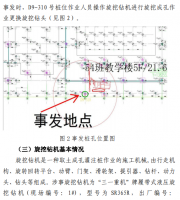

The workers of wire head processing should be operated by trained licensed personnel, and the operators of the same machine cannot be changed at will.

construction process ① reinforcement blanking ② reinforcement section flat head ③ rolling thread processing ④ screw head quality inspection ⑤ capped protection ⑥ on-site connection ⑦ construction inspection II.

before threading, the grinding wheel cutter shall be used to grind the threading, and then the through-stop gauge shall be used for inspection.

After the installation of the sleeve, the torque value shall be tested according to the acceptance requirements.

The rib stripping rolling straight thread sleeve connection in mechanical connection is widely used at present.

The screw heads passing the inspection shall be protected by the sleeve head and stacked by classification and code.

For more information, please check the historical messages after following In reinforced concrete construction engineering, there are three connection methods of reinforcement: welding, mechanical connection and binding connection.

[disclosure content] i.

Qualification rate requirements: the sampling qualification rate of connecting sleeve or lock nut shall not be less than 95%.

Reinforcement straight thread connection, i.e.

The processing length of the steel wire head is generally two wires more than the fair difference (half of the sleeve length) (the number of complete screw threads).

Before formwork assembly and concrete pouring, the site shall be inspected to see whether the materials are cleaned to avoid unnecessary waste.

The acceptance examples of sleeve materials shall be shared ↓↓↓· during data inspection and supply, The joint type inspection report of corresponding joint performance grade and the mechanical performance inspection report of sleeve raw materials must be provided at the same time.

If the pass rate is still less than 95%, the batch of products shall be inspected one by one, and the qualified products can be used.

After the screw head is processed, it shall be screwed with a sleeve to ensure the service quality, and a protective cap shall be set for protection (because the reinforcement is easy to rust after breaking the oxide layer).

Construction process index control ① Sleeve ② Rebar processing screw head ③ Examples of key points for processing straight thread of connecting joint reinforcement ↓↓↓ the reinforcement thread processed on site shall not have thread string, discontinuity of thread opening, etc.

The contents filled in the sampling sheet shall include the entrusting unit, project name, construction unit, sampling time, reinforcement manufacturer or place of origin, reinforcement grade or brand, reinforcement specification, welding connection mode, use position, number of test pieces, required inspection items, sampler, witness, witness number, etc.

500 joints of the same grade and specification of the same batch of materials under the same construction conditions shall be inspected and accepted as one acceptance batch.

In the reinforcement binding stage, you should often go to the site to check the use (whether it is wasted) and whether the use method is correct.

When the qualified rate of sampling inspection is less than 95%, another product of the same quantity shall be selected for re inspection.

Wire head processing is that both ends of the reinforcement shall be cut flat (with grinding wheel cutting machine, gas cutting is strictly prohibited) to ensure the flatness of the reinforcement end, so that the installation torque can effectively counter the jacking force against each other, so as to eliminate or reduce the deformation caused by the thread gap when the reinforcement is pulled.

6.

The unqualified products shall be returned to the manufacturer for treatment· Other precautions 1.

Before the workers start processing, they should start processing only after the process inspection of the thread head made by the workers is qualified, so as to avoid losses caused by blind mass processing.

▲ This table is for reference only.

When the total pass rate of the two inspections is not less than 95%, the batch of products is qualified.

Of course, you can also check whether the torque of the mechanical connection reaches the strength (for example, press down with a torque wrench against your own weight to see if it can be pressed).

Three dimensional technical disclosure of reinforcement straight thread connection construction ↓↓▲ Video – Technical Center of China Railway fourth Bureau Construction Engineering Co., Ltd.

reinforcement rib stripping and rolling straight thread sleeve connection, is a mechanical connection method that uses a special rolling machine to roll the end of the reinforcement through the cold work hardening method, so as to make the end of the reinforcement to be connected produce plastic deformation and form threads, and then connect the two reinforcement together with the internal thread sleeve corresponding to its threads.

The through gauge can be screwed in smoothly and meet the required screw in length.

▲ Straight thread sleeve sample · visual inspection: the thread profile of the connecting sleeve shall be full, the surface of the connecting sleeve shall be free of cracks, and the surface and internal threads shall be free of serious corrosion and other visible defects· Dimension inspection important dimensions (outer diameter and length), thread profile and accuracy shall be inspected to meet the requirements of the manufacturer’s product design drawings.

Through three-dimensional technical disclosure video and implementation case analysis, this paper comprehensively summarizes the key points of reinforcement straight thread connection construction technology for your reference.

3.

▲ in the joint type inspection report, the standard sleeve is used for the connection of excavated foundation reinforcement and integrally hoisted reinforcement cage, and the reinforcement cage that needs to be hoisted by sections adopts positive and negative screw thread flared type or lock nut type (generally not used).

If there are less than 500 joints, they shall also be regarded as one acceptance batch.

The internal thread shall be inspected with a special thread plug gauge, the plug through gauge shall be able to be screwed in smoothly, and the screw in length of the plug stop gauge shall not exceed 3P (P is a pitch length).

If the copyright of the work is involved, please contact us and we will delete the content at the first time! Details of advanced training courses on fine management of construction project cost, EPC project investment control, contract pricing and settlement management and whole process engineering consulting operation in the new era after the implementation of civil code and judicial interpretation of engineering contract (I), the whole process control of construction project risk and the whole process actual combat of EPC project and the new version of EPC contract model text Details of special training course 2021 actual combat ability improvement of chief engineer and technical director of excellent construction projects details of special training course grasp the development trend of construction industry and provide the latest policies, information and knowledge of construction industry in time! Long click the QR code below to focus on “information platform in engineering field”..

Allowable deviation: sleeve diameter D ≤ 50; Allowable deviation of outer diameter ± 0.5; The allowable length deviation is ± 0.5· General test items for sampling and inspection: tensile strength.

2.

5.

4.

The screw in of non-stop gauge shall not exceed 2.5P, and the sampling quantity shall be 10%, The inspection qualification rate shall not be less than 95%, the length of the screw head shall be 1 / 2 of the sleeve length, and the tolerance shall be 0 ~ 2p.

When reviewing the type inspection report, attention shall be paid to: ① the basic parameters of the joint specimen must be recorded in detail in the inspection report; ② The inspection report shall not exceed 4 years; ③ Type inspection report is only required for standard joints; ④ The type inspection report of HRB500 reinforcement joint can also be used as the type inspection report of HRB400 and HRB335 joints of the same type and grade, otherwise it is not allowed.