Before installing the electric box, snap the control line of the electric box on the plastered surface according to the elevation of other indoor electric boxes.

Process flow 2.

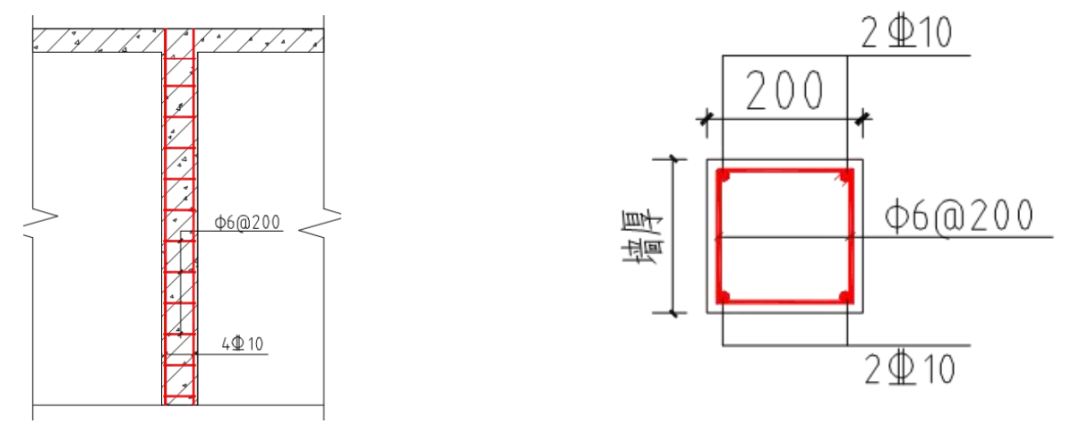

The guide wall and inverted sill shall be built with solid bricks at the bottom of the masonry, and its height can not be less than 200mm.

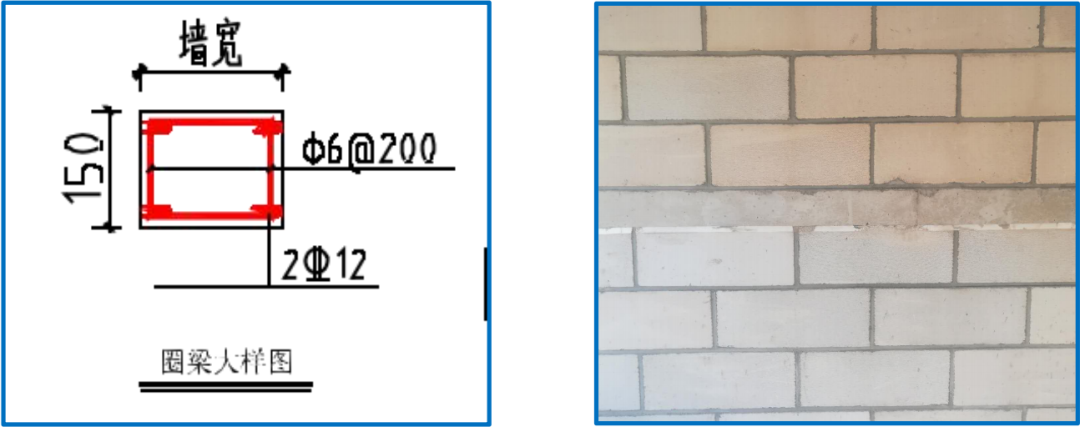

The contact surface with the block shall be pasted with adhesive tape to prevent slurry leakage from the ring beam.

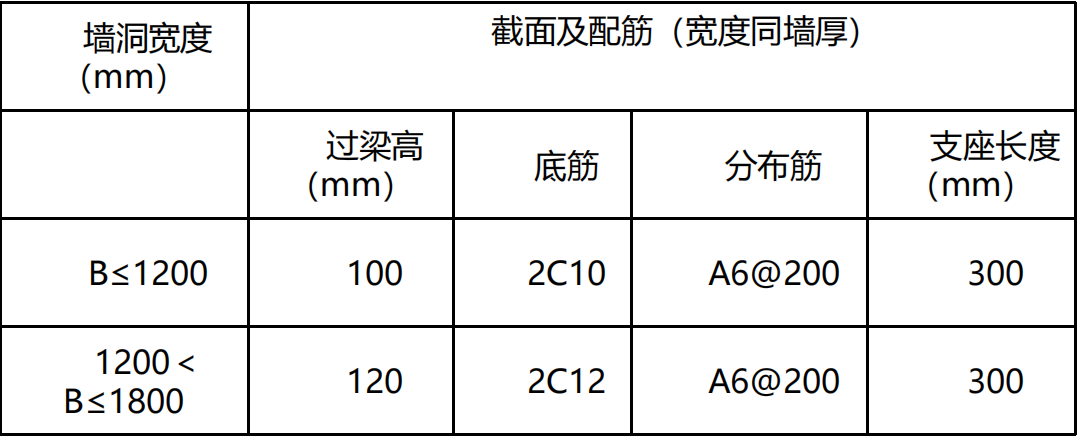

The secondary component centralized processing area includes centralized processing of prefabricated lintels, prefabricated blocks for air conditioning holes, prefabricated blocks at the edges of door and window openings, etc.

Base course cleaning, cleaning floor base course soil, slurry and other sundries, washing with water and dedusting.

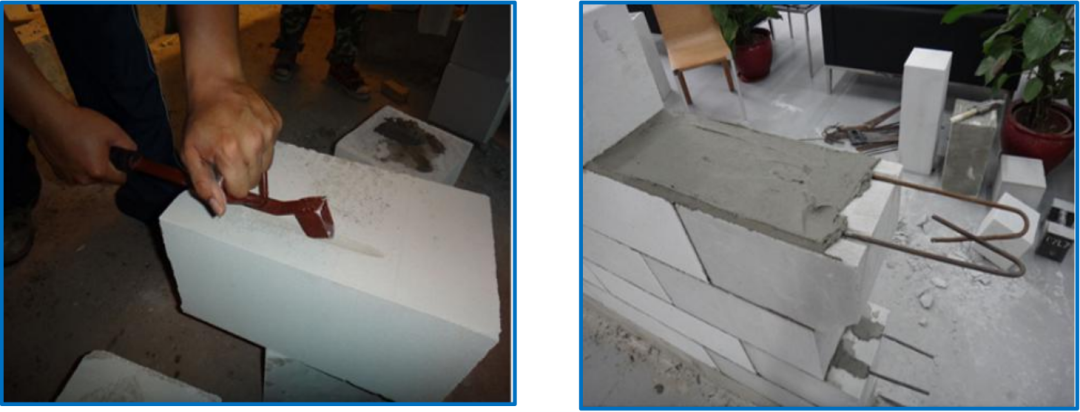

It is strictly prohibited to scrape the middle of the mortar application surface into a concave shape (it is easy to cause the horizontal mortar joint to be hollow).

5.

6.

(3) When the opening is less than 2.1m, concrete precast blocks can be used; Concrete precast blocks shall be set, the first brick from the bottom shall be precast blocks, and one brick shall be set every other brick or 400mm (determined according to the module of the brick) at the upper part.

01 preliminary preparation 1.

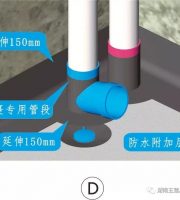

The platform is at least 10cm higher than the periphery and can effectively drain water.

The material stacking blocks shall be stacked and processed in a centralized manner.

(2) The mortar joint shall be horizontal and vertical, 3-5mm wide, 3-5mm deep, plumpness ≥ 90%, staggered up and down, and there shall be no through joint; At the bottom of the first skin block, the slurry height shall be used to ensure that the thickness of the reserved top joint of the wall shall be controlled between 20 ~ 30mm; When the block needs to be sawn, the length of the sawn block shall not be less than 1 / 3 of the total length of the block; The masonry shall be carried out in sequence from the corner or cross wall.

The vertical and horizontal walls shall be built cross, and the overlapping length shall not be less than 1 / 3 of the block length; The masonry corner and the junction (if any) of internal and external walls shall be built at the same time.

The advance and retreat size shall be greater than 60mm.

The secondary prefabricated components shall be poured on site in advance.

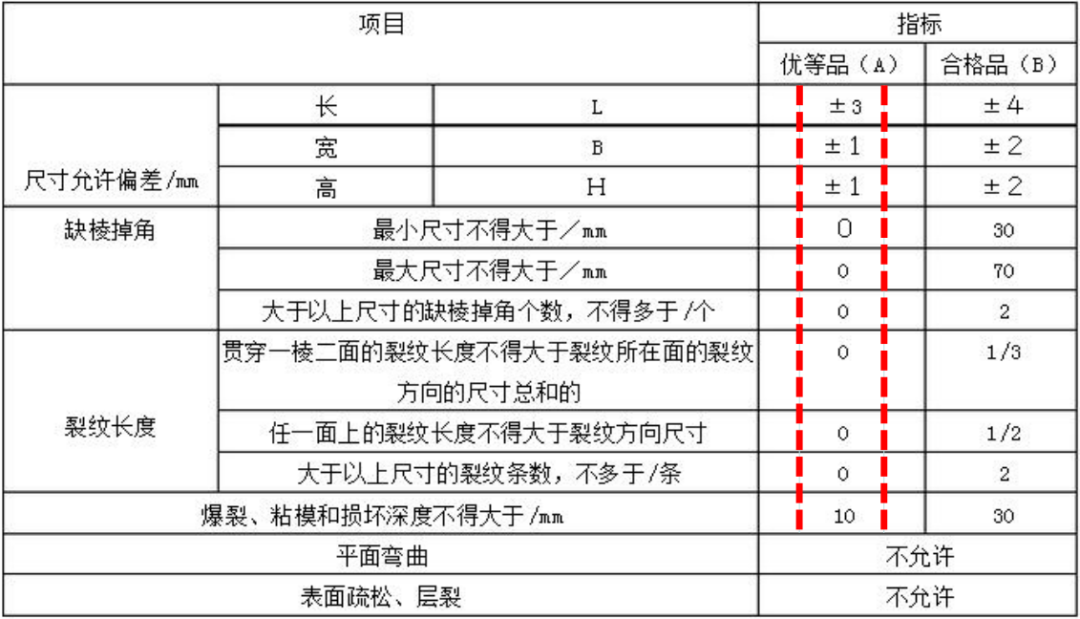

Dimensional deviation and appearance of block 3.

Construction machines and tools 6.

Instead, forklifts or flatcars should be used for transportation, and special personnel should be assigned to transport them to the floor to prevent block breakage.

The requirements for the horizontal positioning elevation of the inverted sill, i.e.

The horizontal projection length of inclined tenon shall not be less than 2 / 3 of the height; After masonry, 2m guiding rule shall be used to compound the perpendicularity and flatness of the wall, and the squareness shall be rechecked with laser level and tape; Recheck the Bay depth with laser rangefinder; Recheck the size of the door opening with a tape measure.

3.

Before slotting, it is required to snap the line, and it is strictly prohibited to dig cross and horizontal grooves.

During pouring, the dustpan opening method is adopted, and the outer side is vibrated and compacted by 20 series vibrating pump.

During formwork erection of structural column, it is not allowed to drill holes on aerated concrete, and the screw can be placed in the column.

shall meet the drawing design requirements; Inspection rules: type inspection + delivery inspection.

7.

4.

The age of the blocks used in the construction of high-precision blocks must reach the specified 28d, and the entry date shall be marked with a brush on the aerated block; Masonry materials shall comply with autoclaved aerated concrete (GB11968-2006) Concrete blocks; Appearance requirements: no missing edges, corners and cracks; Allowable dimension deviation: length L: - 3mm ~ 0mm; wide Degree B: ± 1mm; Height H: ± 1mm; (basic characteristics of high-precision block) physical performance indexes: dry density, strength grade, drying shrinkage Frost resistance, etc.

After the pipe is placed in the slot, it shall be fixed every 0.5m; When there are less than 2 pipes in the groove: wet the pipe groove with water first, and then repair it with cement mortar of a higher grade (the strength grade of mortar shall not be lower than M10); When there are more than 3 pipes in the trench: first fill the trench with fine aggregate concrete, and then hang the steel wire mesh (the width of the steel wire mesh shall not be less than 10cm beyond both sides of the trench).

The whole brick shall be used for masonry layout as far as possible, and the number of non-standard bricks shall be controlled; Avoid through seam during typesetting; The gap control of typesetting top brick is adjusted through the height of guide wall or base slurry; Adjust the top brick gap (20 ~ 30mm) through the height of guide wall or grout base; Determine the net size of the main masonry room, the net size of the wall after plastering, the finished surface size of the kitchen flue and tube well, the finished surface size of the guest bathroom flue and tube well, the finished surface size of the main bathroom tube well, and the finished surface size of the flue tube well in the cloakroom through the sample room.

(it is recommended to use shaped steel formwork to improve the quality of prefabricated blocks).

Long distance cutting (no more than 1m) shall not be carried out at the same horizontal elevation of the wall at the same time; Slotting width and depth: the width of the pipe slot is 10mm larger than the outer diameter of the pipe, and the slot depth is d + 15mm.

Wall laying control line after surveying and setting out: snap the control line, door and window opening position line and “forehand wall” survival surface control line at each post built infill wall, and project them at the corresponding positions of the top plate and side wall (also known as heaven and earth line); Room squareness control line: in the room with rear wall, pop up 300 control lines to ensure the squareness of the room, and lead out the control lines on the wall to prevent plastering mortar from covering the control lines; Elevation control line: lead the indoor elevation 1m control line to the wall after plastering.

During the secondary transfer of material transportation and construction, it is strictly prohibited to use bucket trucks.

Special L-shaped iron parts (factory certificate + test report) are right angle iron parts made of galvanized steel sheet through mold folding and drilling; Specification: 300 × eighty × 1.2 (thickness) corresponding wall thickness: 150, 200, 250; Specification: 240 × sixty × 1.0 (thick) corresponding wall thickness: 100.

(4) (5) structural column: in case of non one-time pouring, the horse tooth tenon shall retreat first and then advance.

Inverted sill shall be set at the partition wall of the toilet, which shall be poured with the main body, and its height shall not be less than 200mm on the ground.

Special adhesive The dry mixed mortar is made of high molecular polymer and hydraulic silicate materials as the main raw materials and a variety of high molecular additives through high-precision measurement and uniform mixing in professional factories.

Centralized processing shall be carried out uniformly according to the masonry layout drawing; Temporary cutting of floors is prohibited; √ Do a good job in the four standardization requirements of masonry: “standardization of masonry drawings”, “single work under materials”, “visualization of process management” and “tidiness of on-site construction”.

After the blocks are transported from the manufacturer to the construction site, they shall be covered with a film transported to the site with the materials or equipped with a “upper cover and lower pad” centralized stacking site, that is, a shed shall be built above, and the outer eaves of the shed shall be at least 1m beyond the outside of the blocks to effectively prevent rain; The lower part is paved with square timber and formwork.

11.

4.

The junction box shall not be fixed during masonry, but shall be fixed at the plastering stage; The spacing of side-by-side pipes shall be greater than 15mm..

Pipeline slotting masonry pipeline slotting: after the masonry mortar reaches a certain strength (greater than 70% of the design strength), a special slotting machine shall be used for slotting.

The sundries on the wall, reinforcement and ground in the structural column shall be cleaned, and the dust and dirt on the wall surface shall be removed with a broom.

Attention, there are more dry goods 02 process flow 1.

9.

(adjust the top plug gap with the inverted sill) 5.

10.

The temporary break that cannot be built at the same time and must be left with tenon shall be built into inclined tenon.

The masonry is not optimized.

Deepen the control of masonry and customize non-standard blocks according to the depth of concrete tongue and groove; Example: 200mm wide shear wall, groove depth 8mm on each side, masonry size 180mm.

12.

2.

8.

Ø the vertical mortar joint of masonry shall be 100% grouted on one end face of the block; The tooth scraper shall be used for horizontal mortar application, and a layer of mortar with a thickness of about 5mm shall be fully scraped.

Wall masonry method (1) special adhesive masonry, stir at low speed, stir for about 1 minute, then stand still for 2-3 minutes, and stir for 1 minute after the materials are fully matured.

elastic measurement on the structural wall; (if there is no structural wall, it can be copied on the structural reinforcement to control the height) control line of the elevation position of the electric box: reserve the position of the electric box in the back wall.