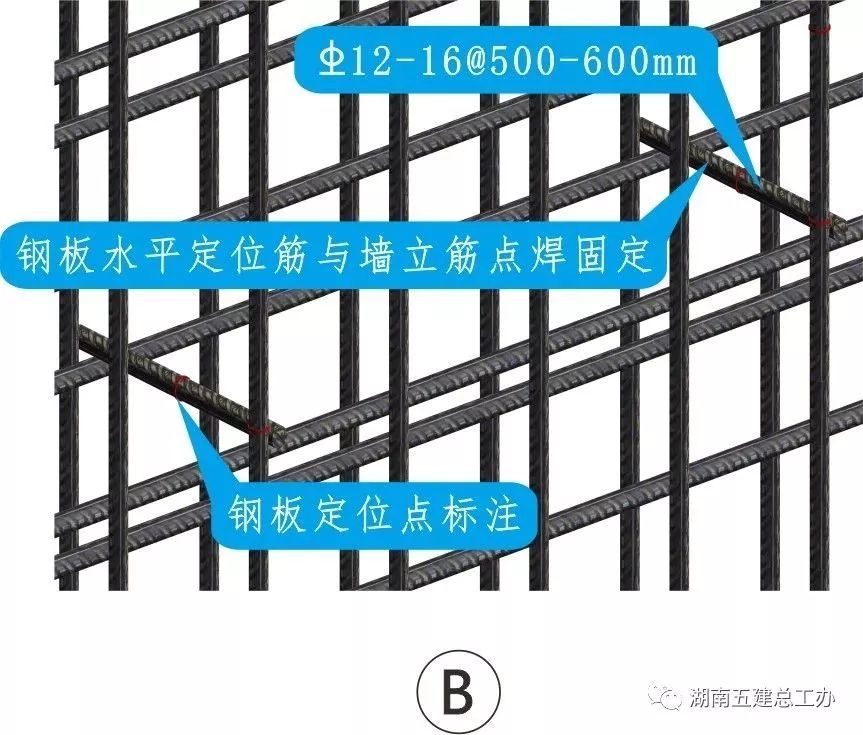

B.

G.

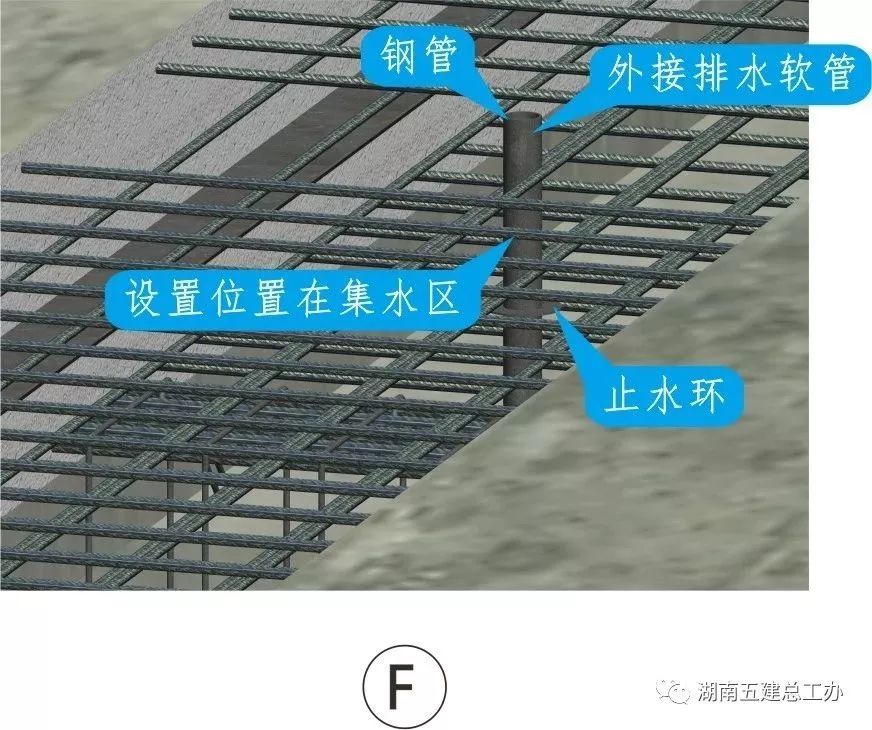

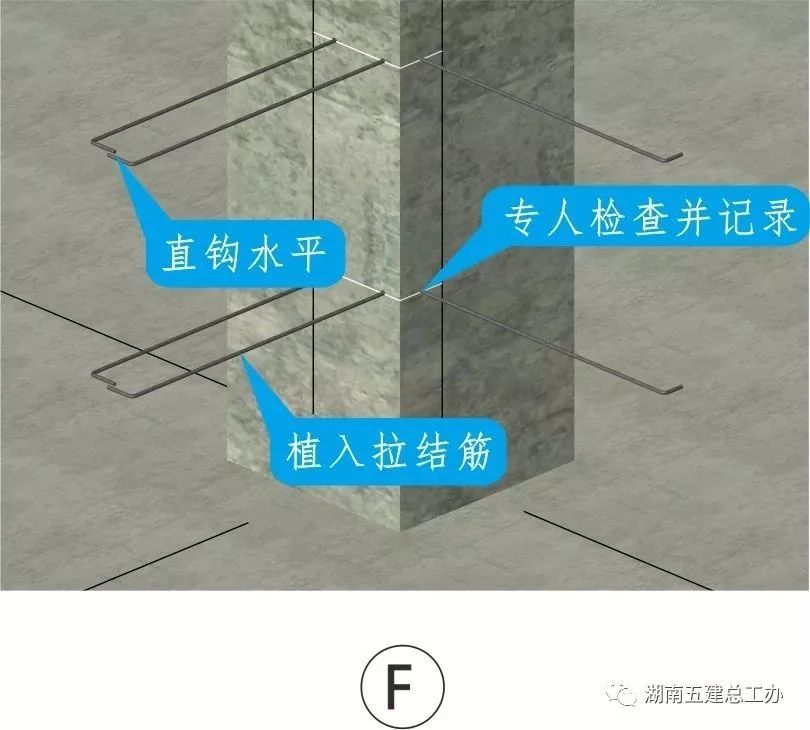

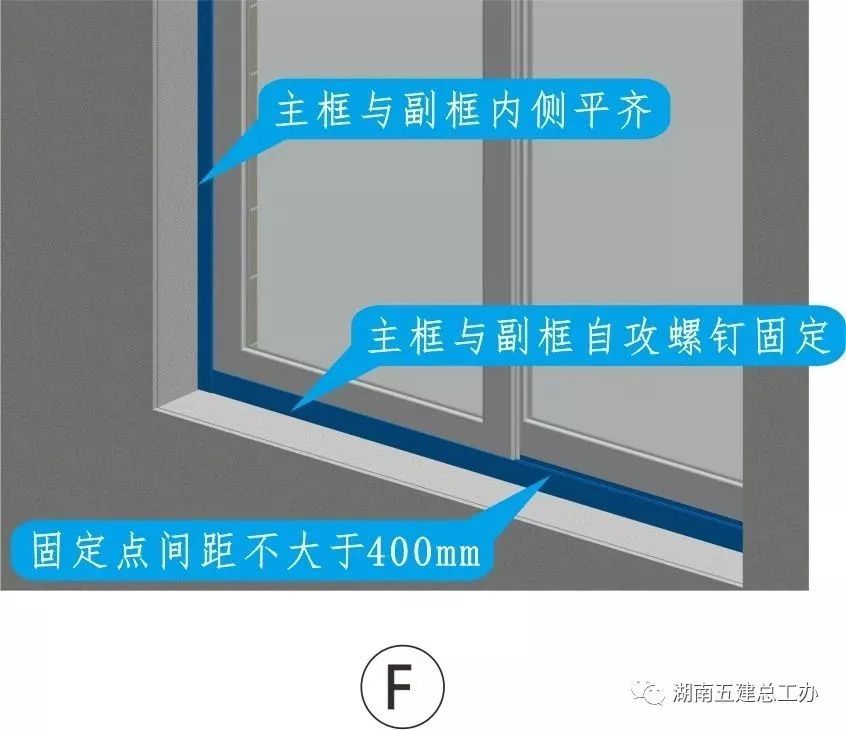

F.

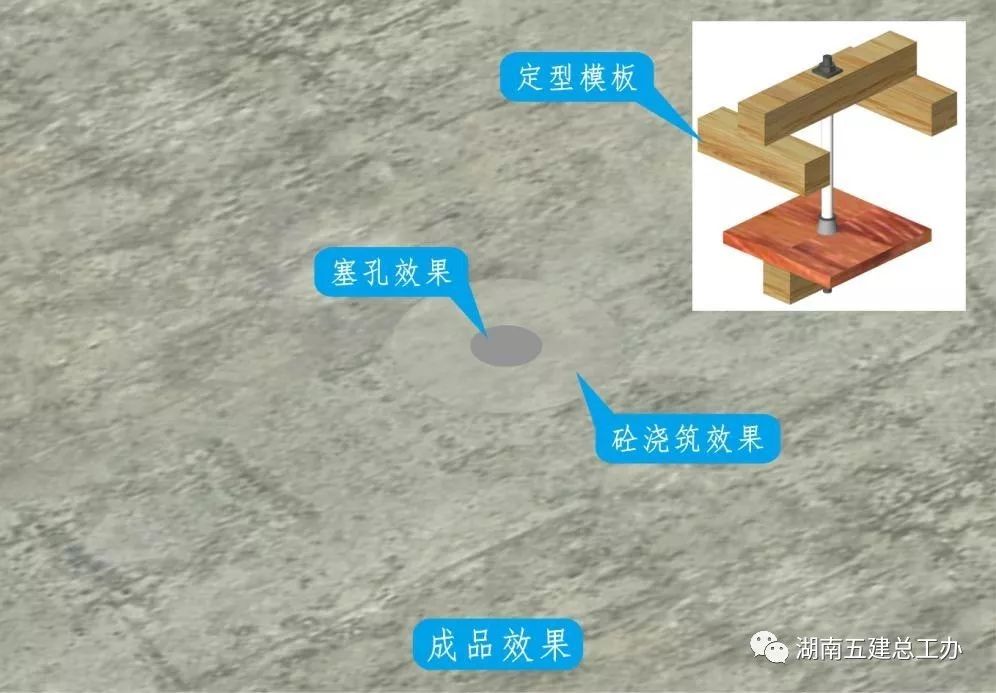

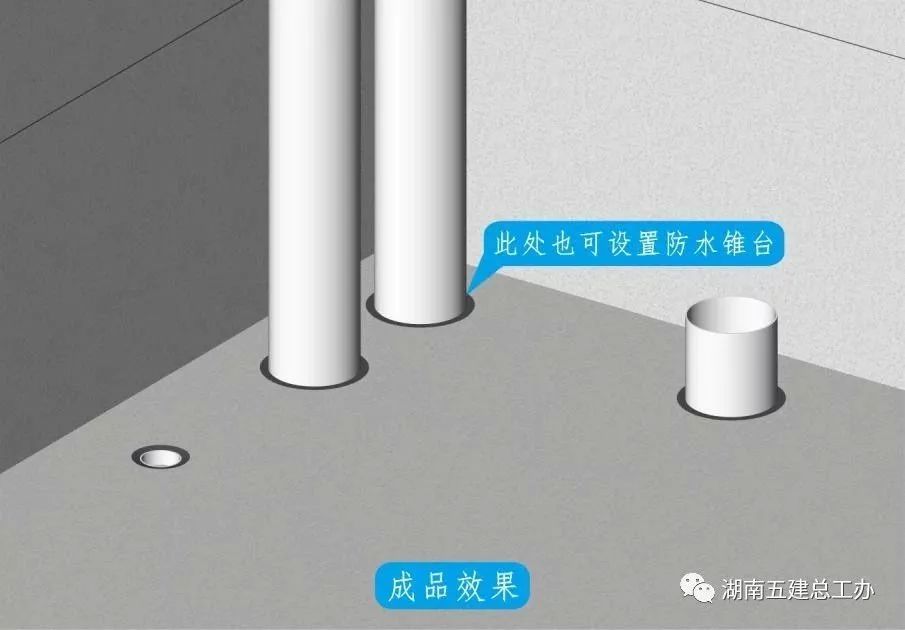

Clean and brush plain cement slurry around the reserved hole, and pour semi dry hard micro expansive fine aggregate concrete twice; Set mold closure at the bottom of the plate; The water storage test shall be conducted for more than 24 hours after completion.

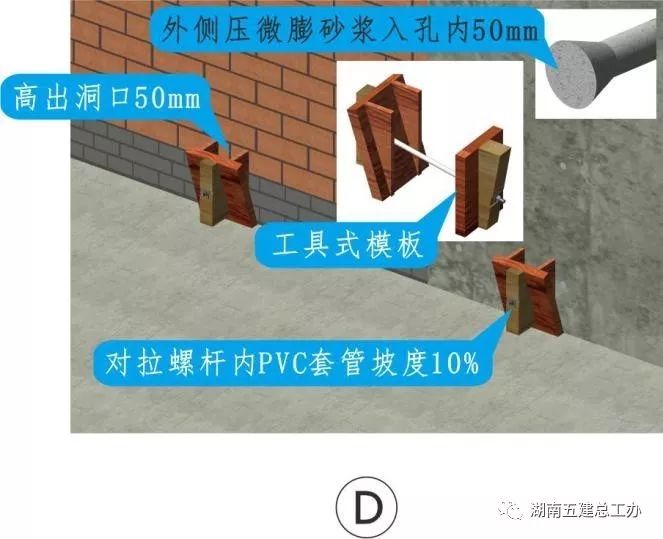

The template adopts the tool shaped template with strong universality, and the adjustable height and width shall be considered when customizing the template; The inside and outside of the screw hole shall be manually pressed into the hole with mortar rubbing long strips.

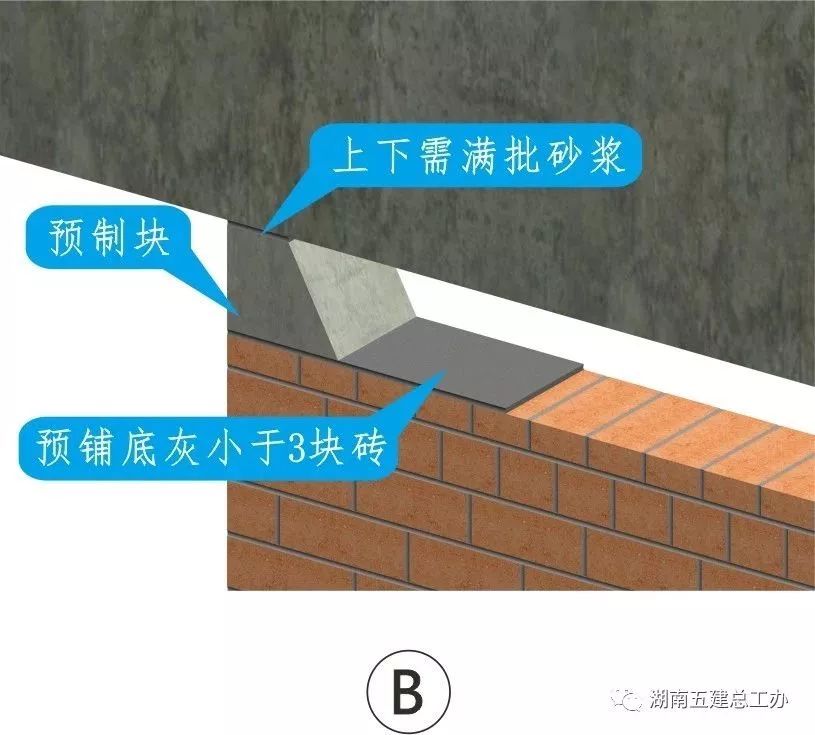

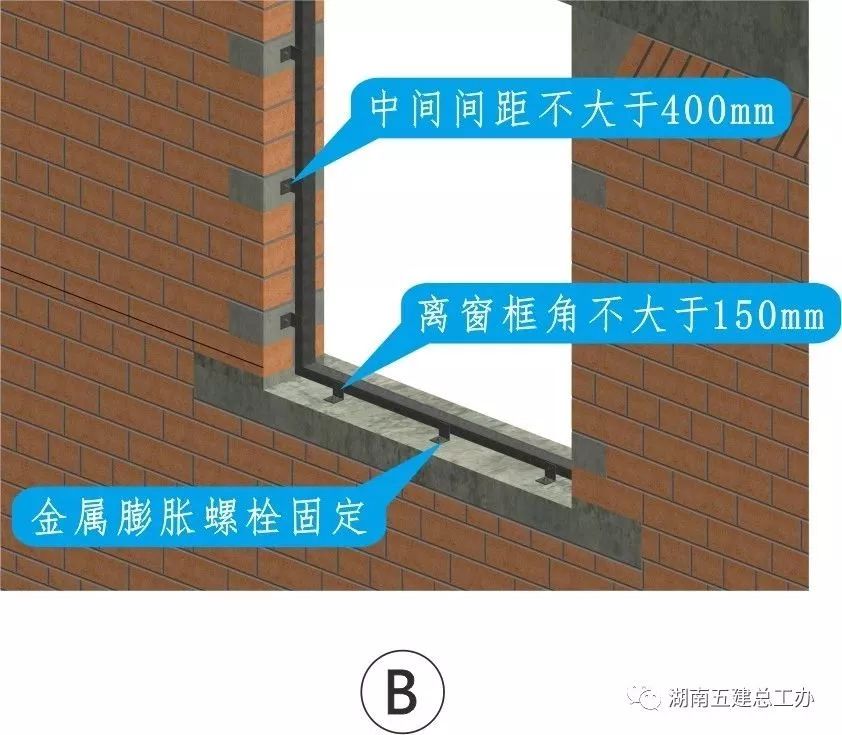

B.

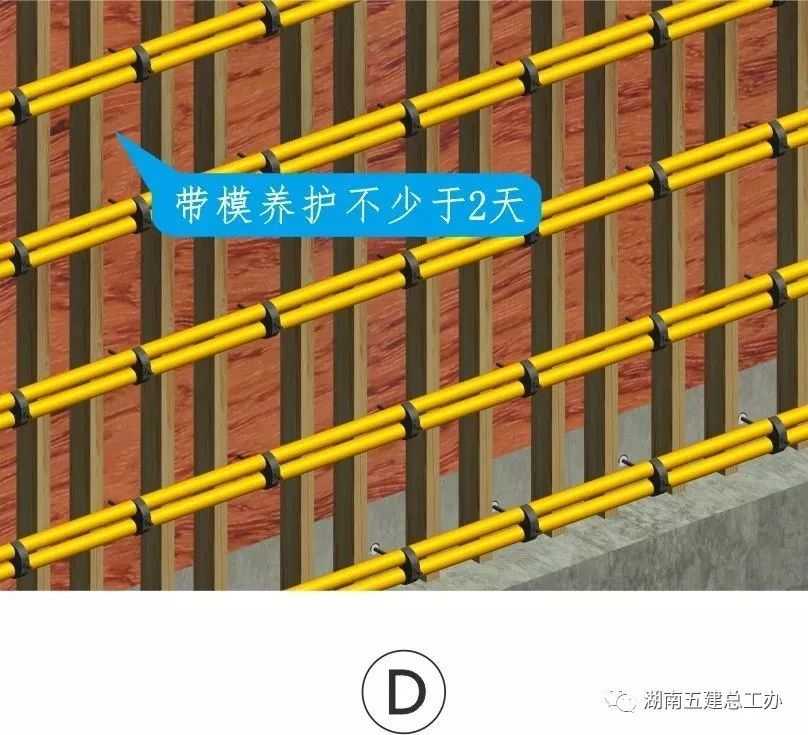

The formwork shall be removed 2 days after pouring, and the formwork shall be maintained during the period.

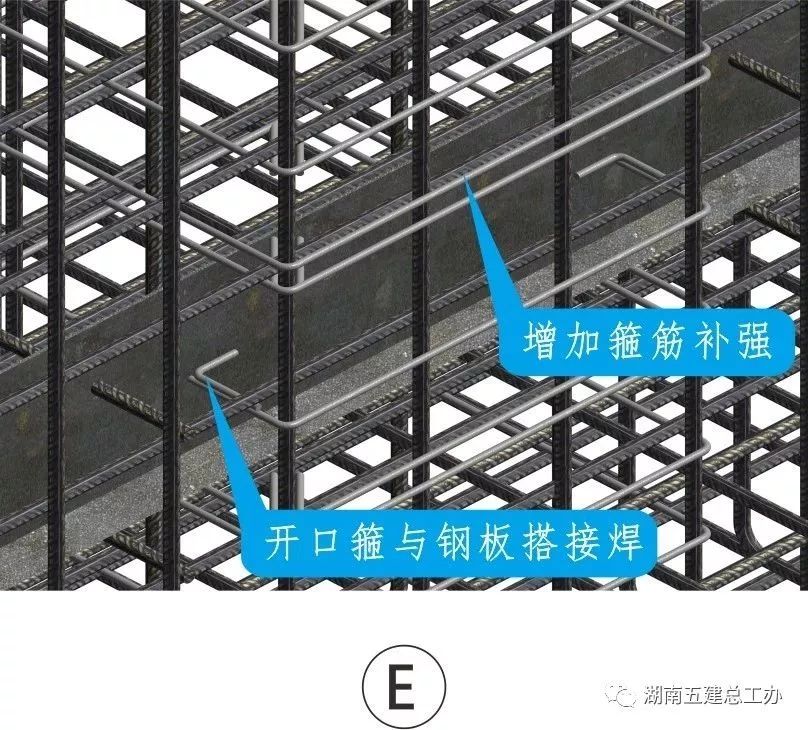

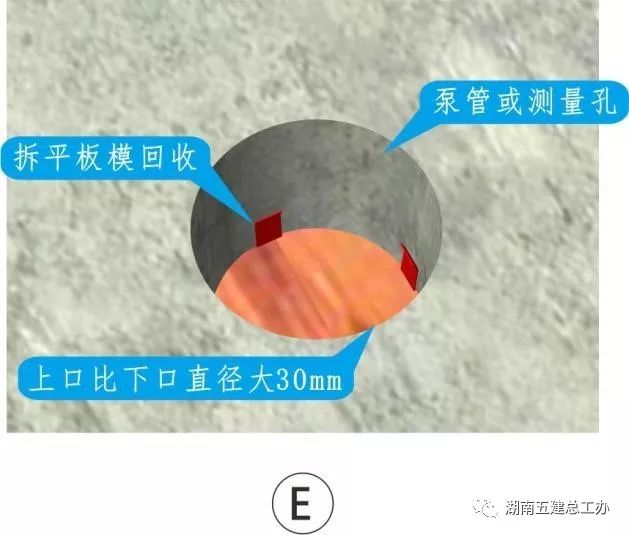

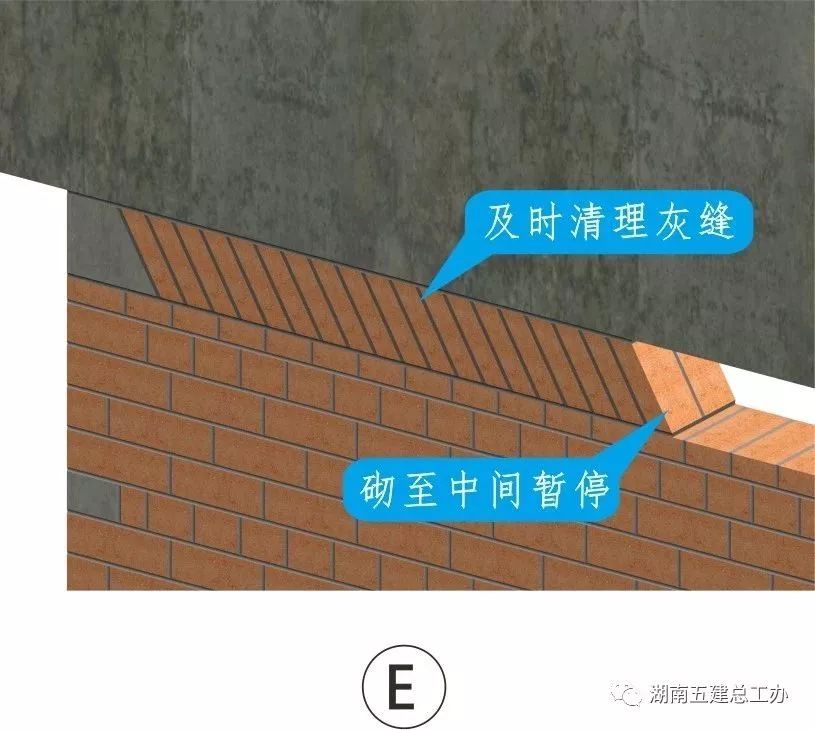

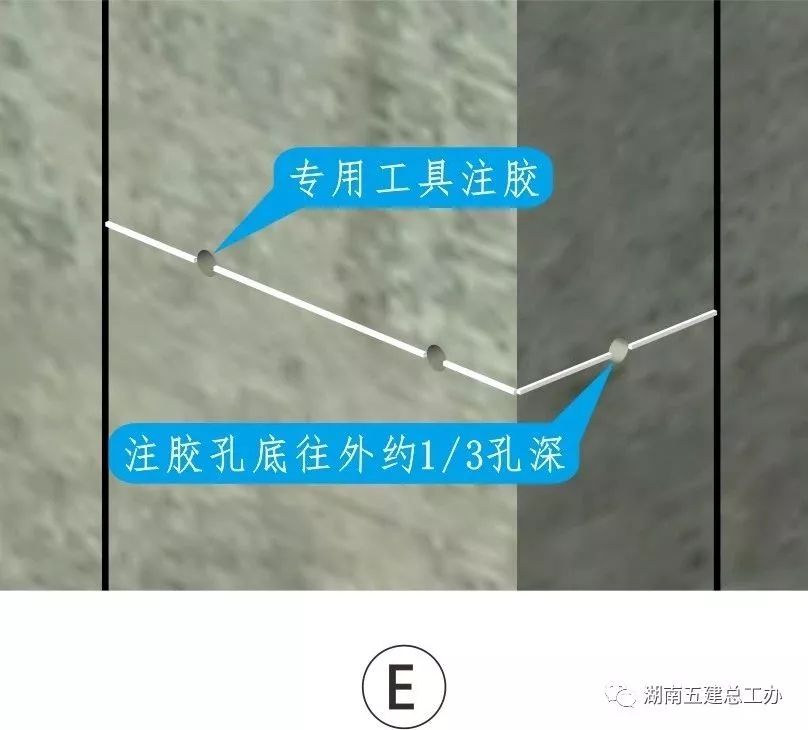

E.

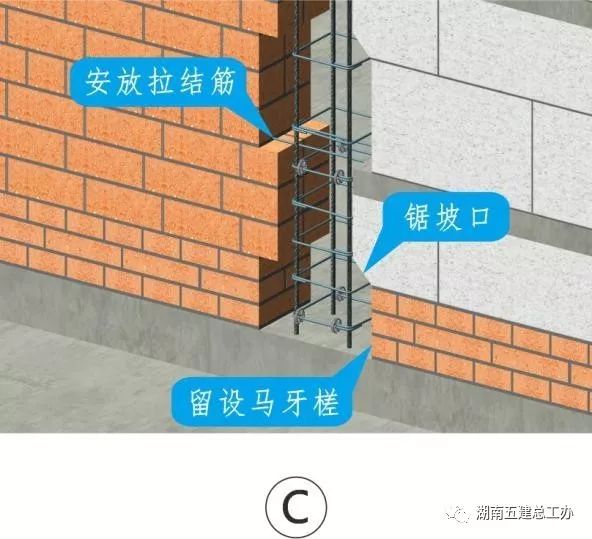

The concrete of the finished structural column is dense, and the surface is flat and smooth; The horse tooth tenon is closely engaged with the masonry, without holes, honeycombs, slurry leakage and wall pollution.

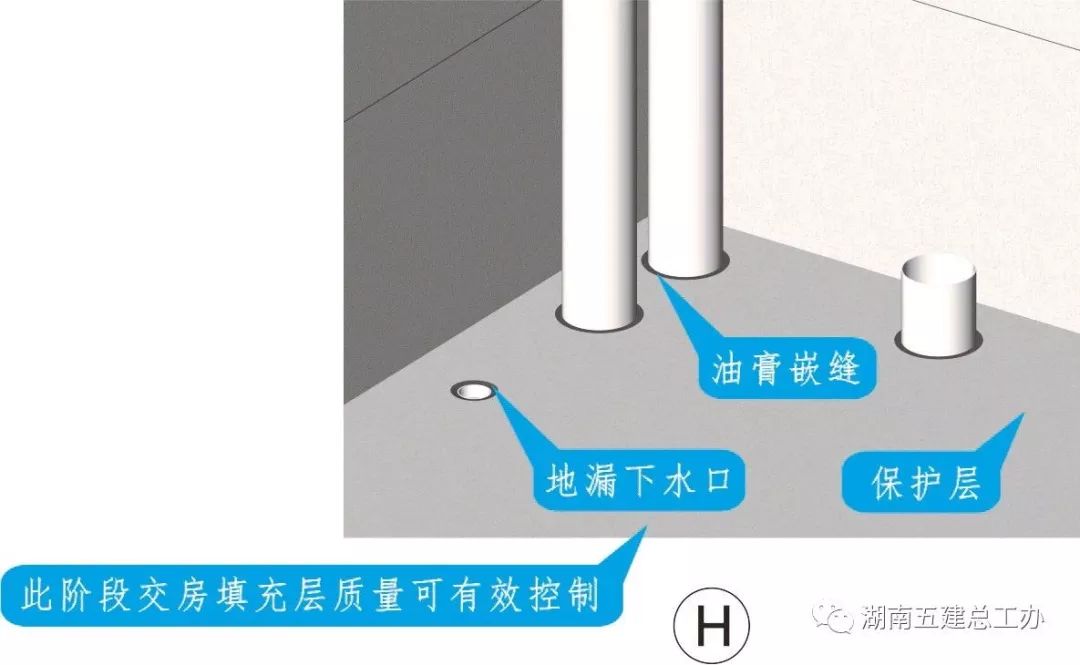

After the water storage test is passed, the floor and wall protective layer shall be constructed immediately, and the wall protective layer shall be connected to the wall waterproof layer.

After the shaped formwork is removed, the plastic pad at the bottom of the slab shall be cleaned in time and repaired with cement mortar, and then the screw holes shall be manually filled in sections with dry hard micro expansion mortar from the upper part of the slab.

After repairing the outside of the hole, scrape and apply 1.0mm thick JS waterproof film in layers and times in time.

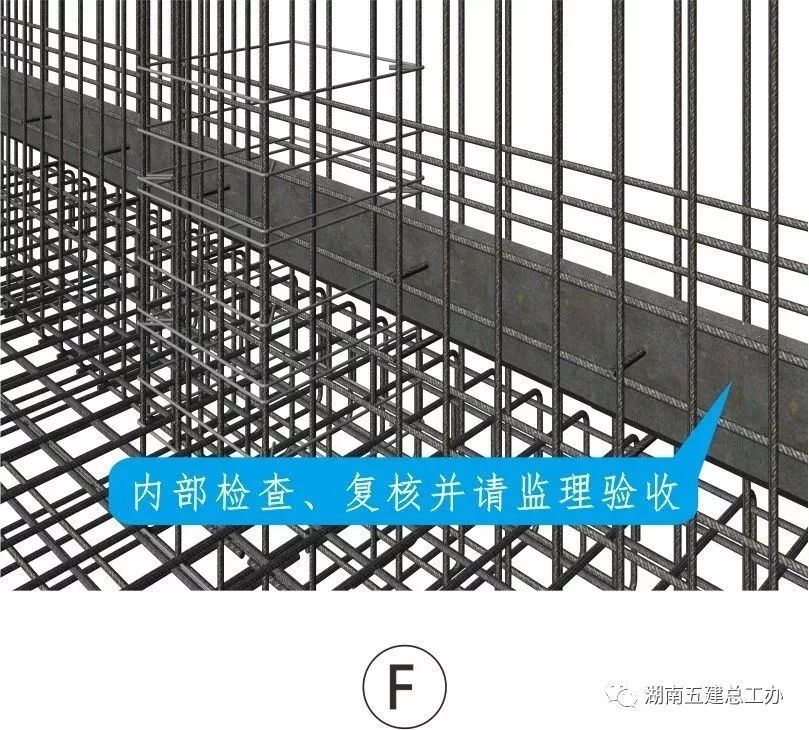

F.

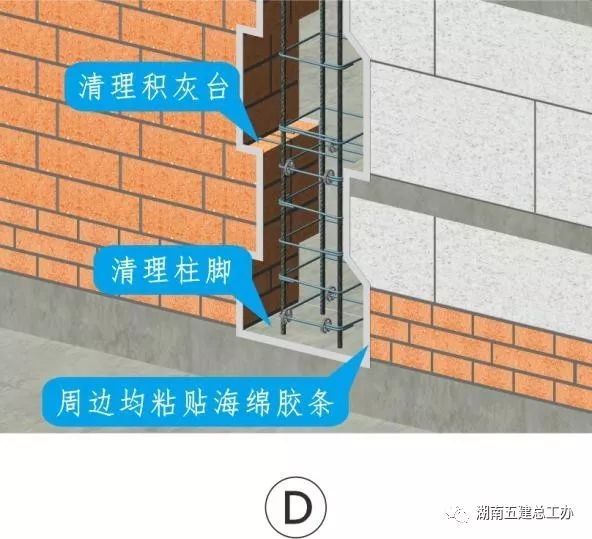

D.

E.

There is no formwork running, slurry leakage, honeycomb, loose concrete and other phenomena at the bottom of the board, and there is no height difference with the bottom of the board.

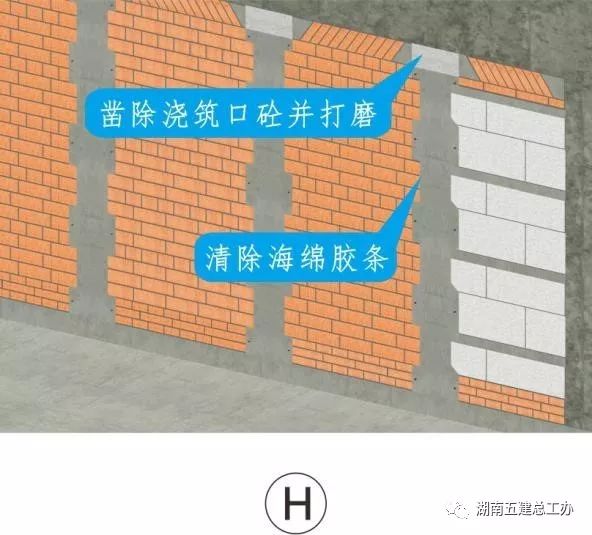

Chisel off the pouring inclined mouth after the coarse aggregate is not loose (3-5 days after pouring), and grind it flat with a hand-held grinder after chiseling; Clean and remove the sponge rubber strip with an ash shovel.

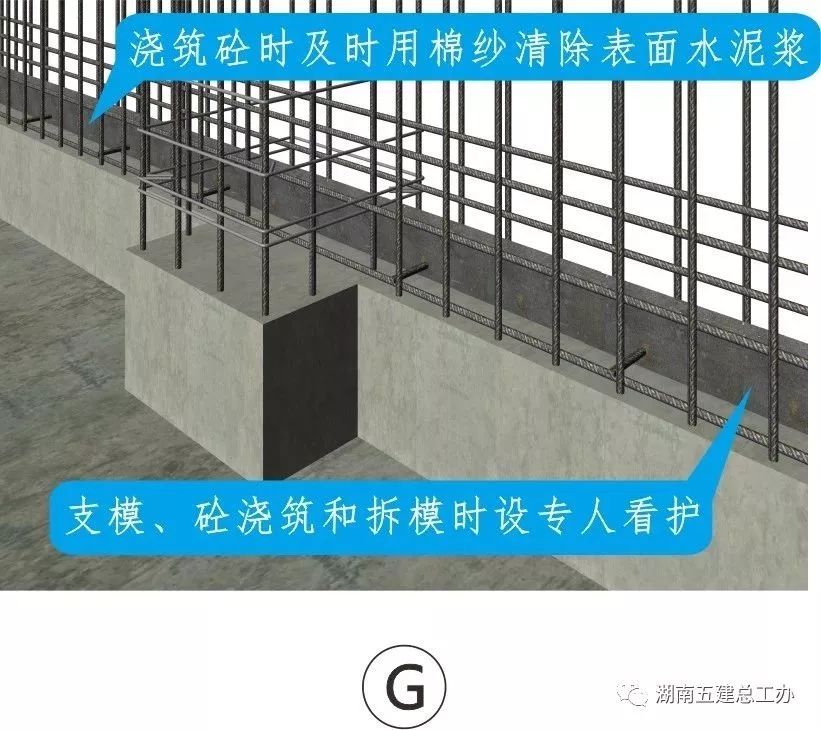

Before pouring, the formwork and column side masonry shall be wetted.

B.

The embedded steel pipe at the pull joint of the outer frame shall be cut off by gas cutting instead of electric welding.

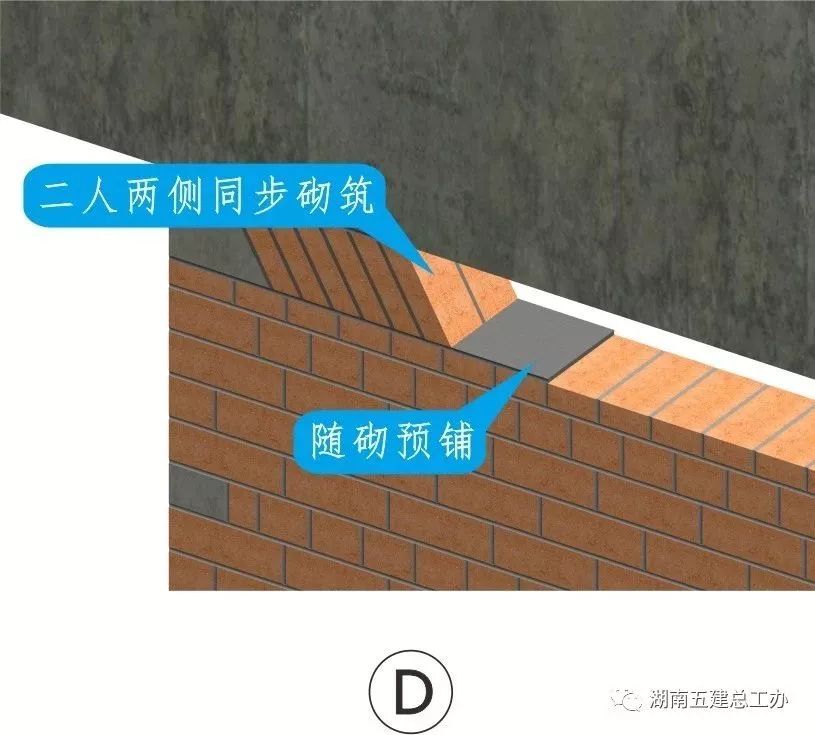

The horse tooth tenon and tie bar shall be reserved according to the design and specification requirements.

In order to prevent the residents from filling with garbage, the construction can transport the light materials indoors before the house is handed over, and the residents sign the certificate of responsibility during decoration.

B.

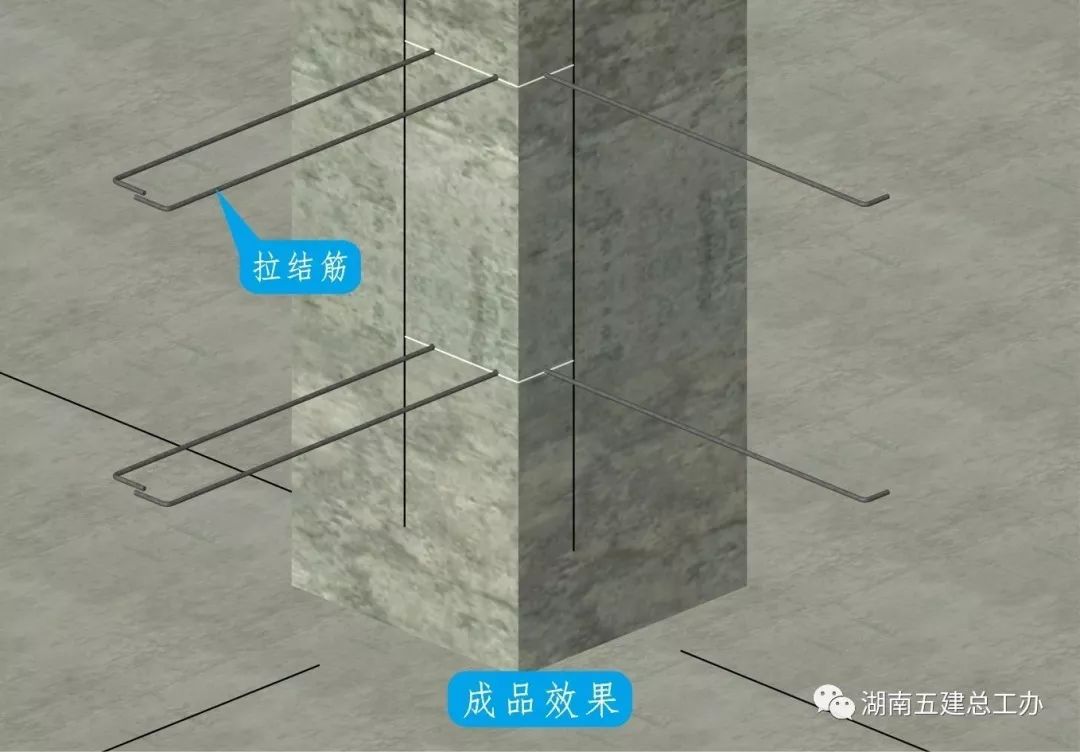

If the deviation of vertical reinforcement is large, chemical planting reinforcement can be adopted, and the planting reinforcement shall meet the requirements of relevant specifications.

The formwork shall be cleaned with sponge tape.

The concrete strength of the finished effect pump pipe and measuring hole is one grade higher than the original design, the concrete is poured and tamped tightly, there is no height difference between the old and new concrete surfaces of the floor slab, the surface is flat and there is no obvious color difference.

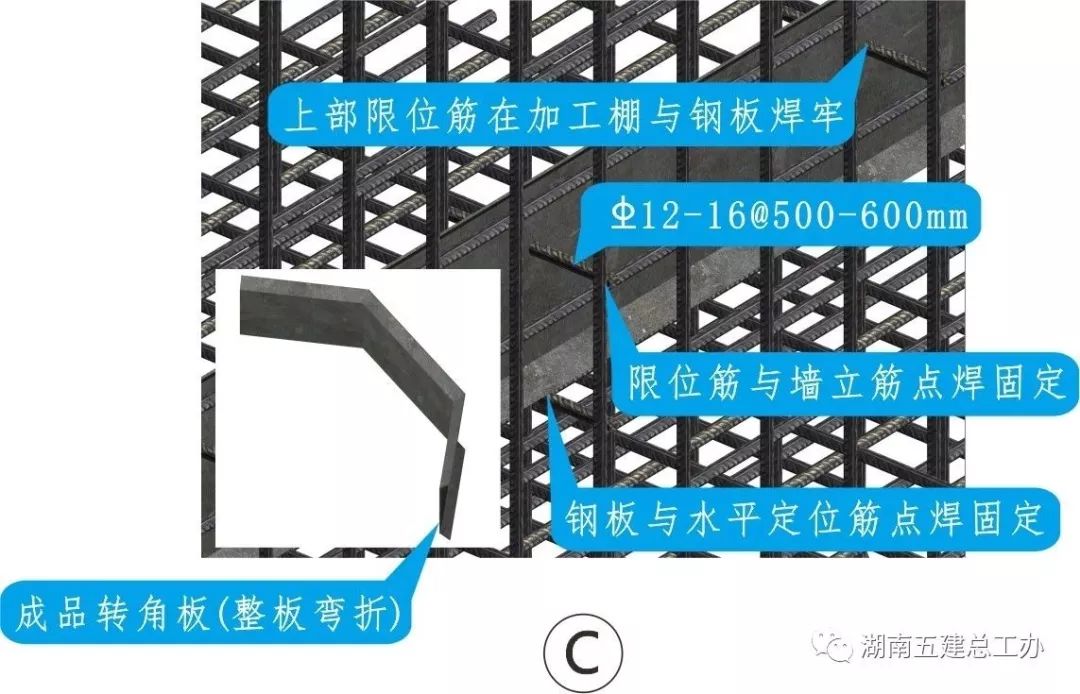

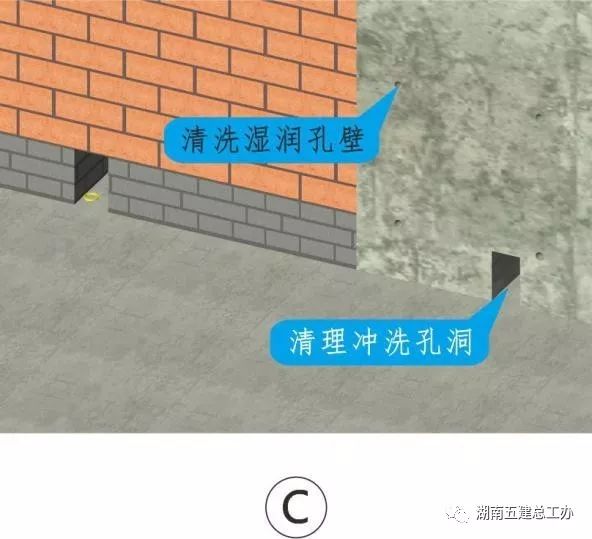

C.

After the formwork is removed, the hole concrete pouring quality shall be checked and the quality defects shall be repaired in time.

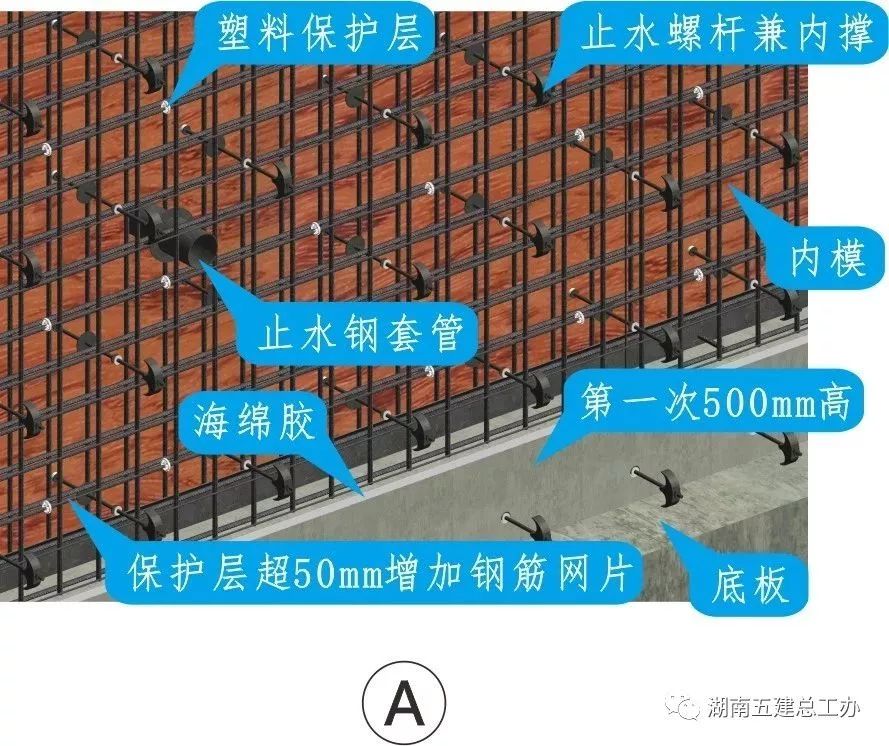

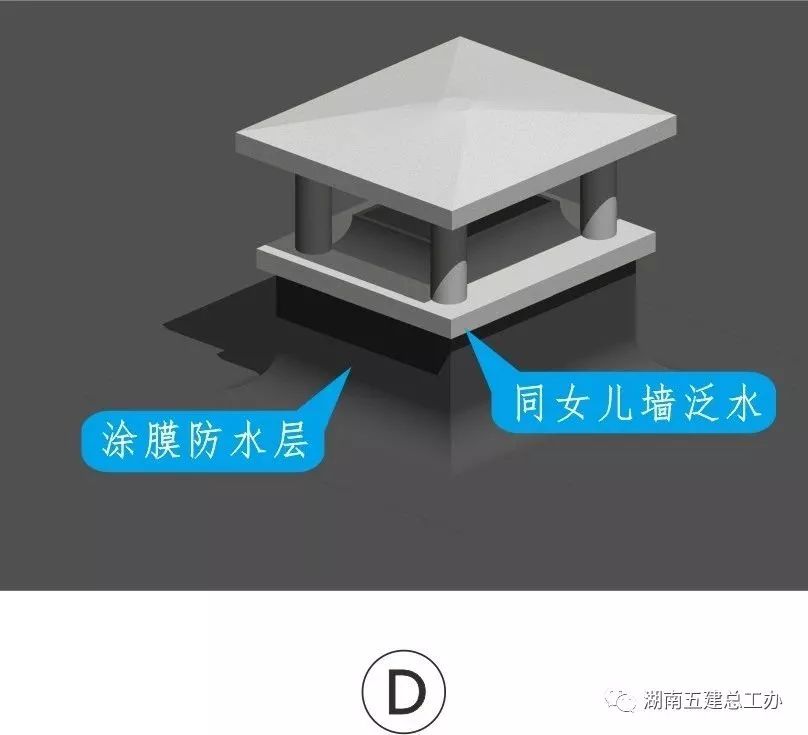

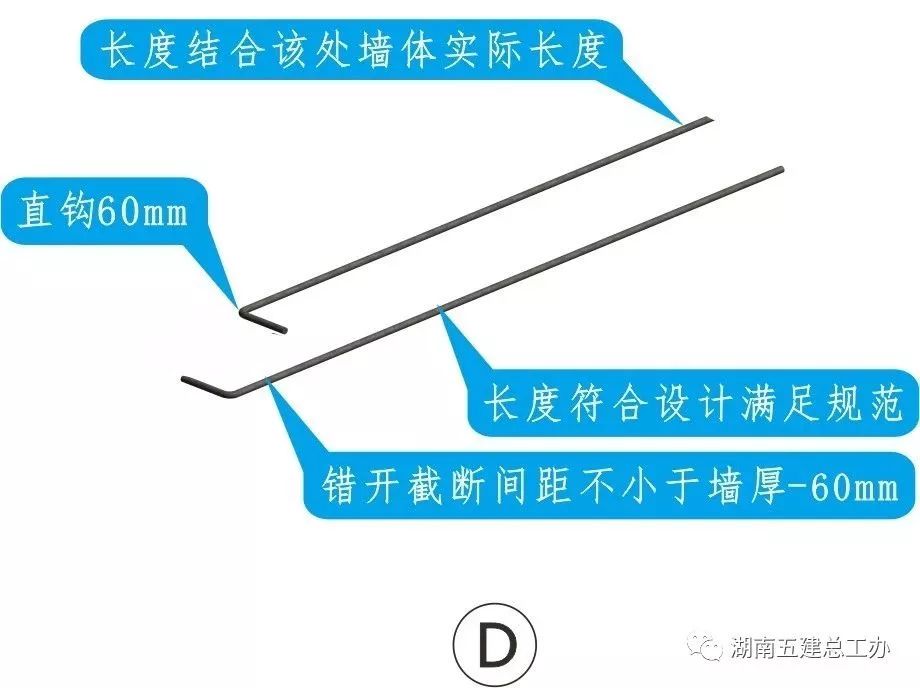

The standardized practices are worthy of our reference and study: (I) ① structural column construction ② floor construction hole construction ③ external wall hole repair (II) ① waterproof of drainage toilet on the same floor ② external wall window installation (with sub frame) ③ Masonry inclined brick top sealing (III) ① basement exterior wall construction ② horizontal construction joint water stop steel plate installation ③ base plate post cast strip pouring (IV) ① roof hood waterproof ② exterior wall window installation (no sub frame) ③ standardization of tie bar planting construction process (I) I.

D.

If the large edge of the hole is less than 100mm, semi dry hard micro expansive fine aggregate concrete or cement mortar can be used for layered, staged pouring or manual filling.

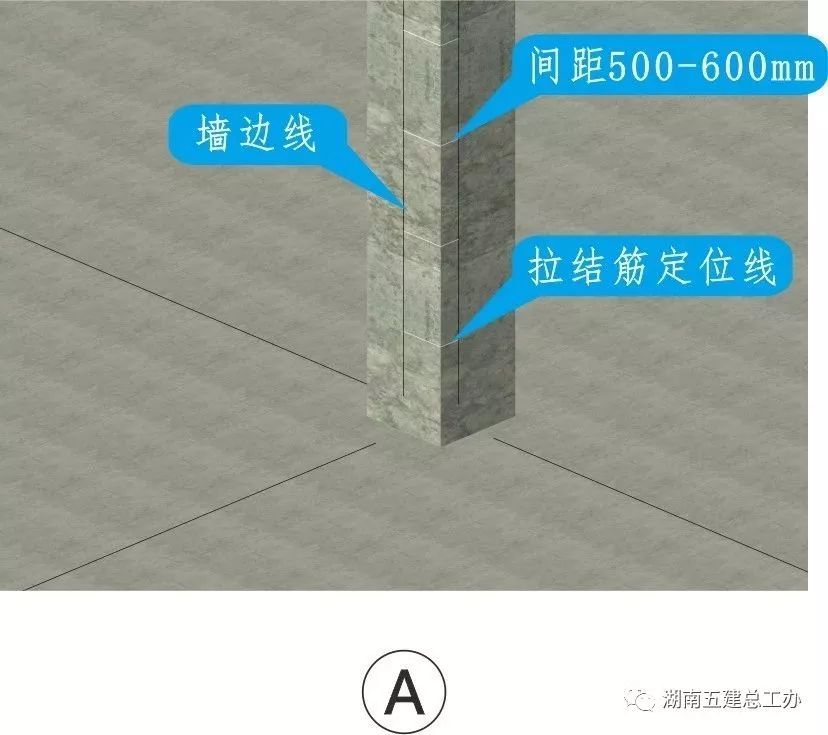

Adjust the position of vertical reinforcement according to the positioning line of structural column.

Originated from the chief engineer office of Hunan fifth construction, this paper interprets the processes and key points of 12 important processes in building construction in the form of three-dimensional diagrams in four chapters.

clean the floor, find out the axis and control line marked during the construction of the main structure, and snap the wall sideline, auxiliary control line and structural column positioning line.

E.

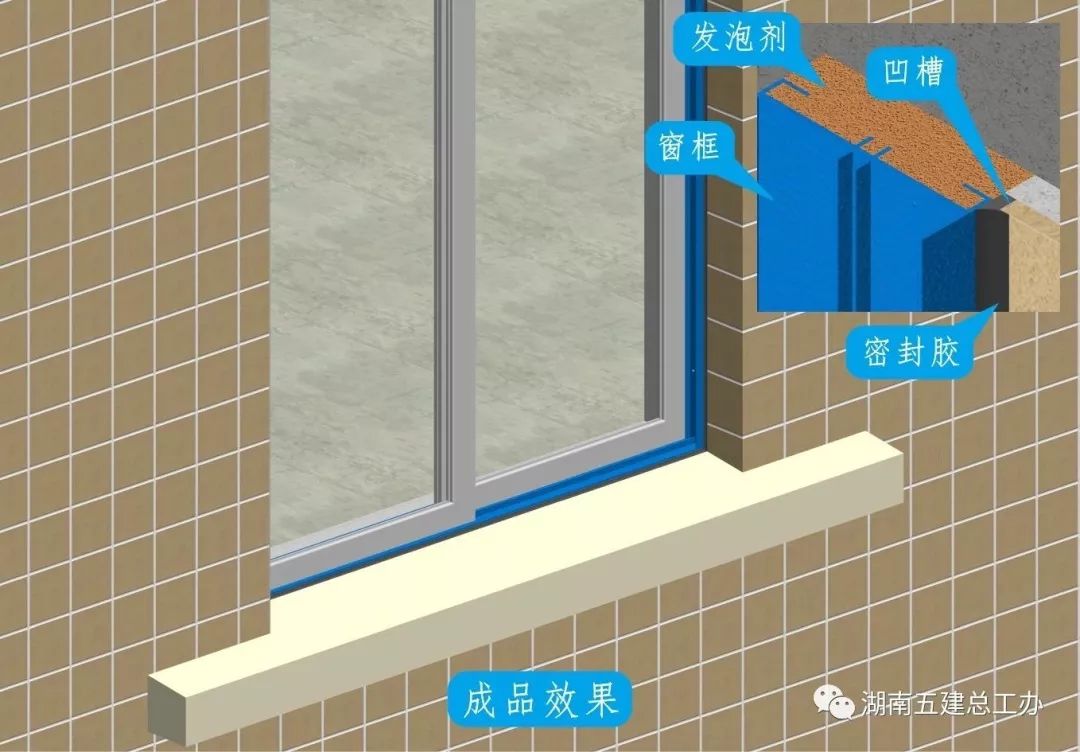

Standardization of construction process (II) I.

F.

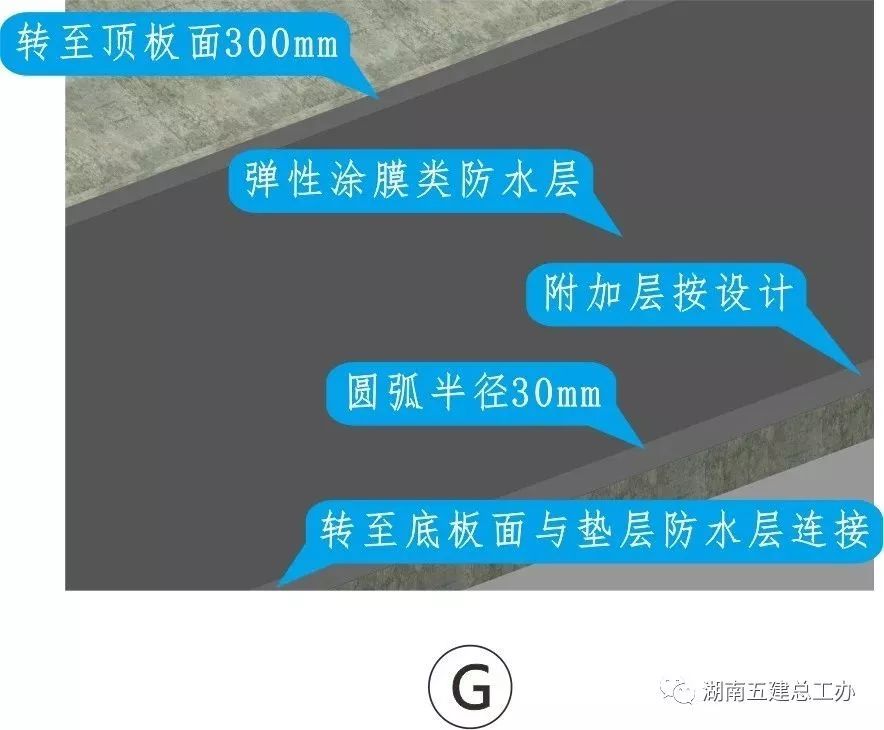

The overall painting shall be carried out in layers.

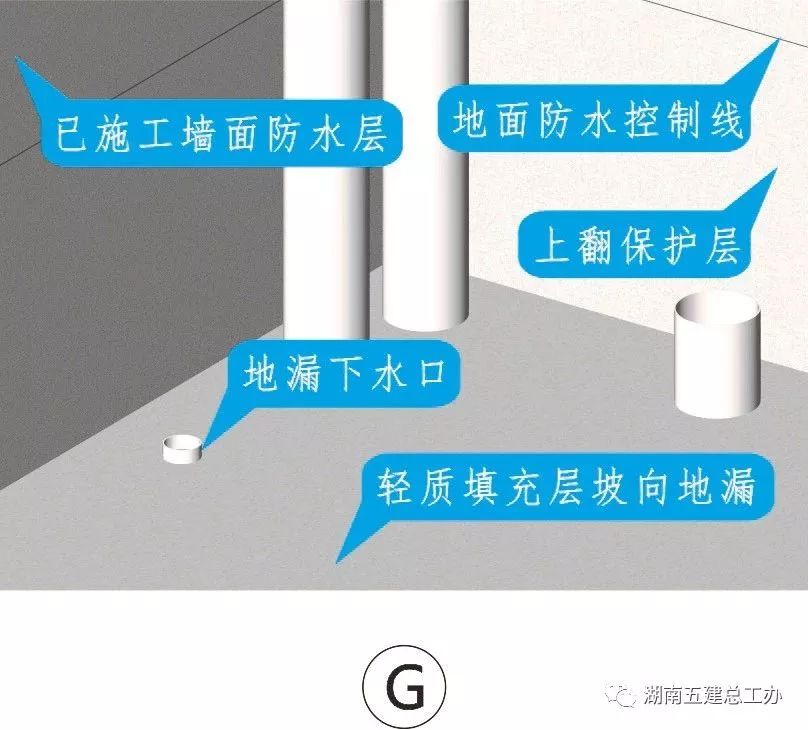

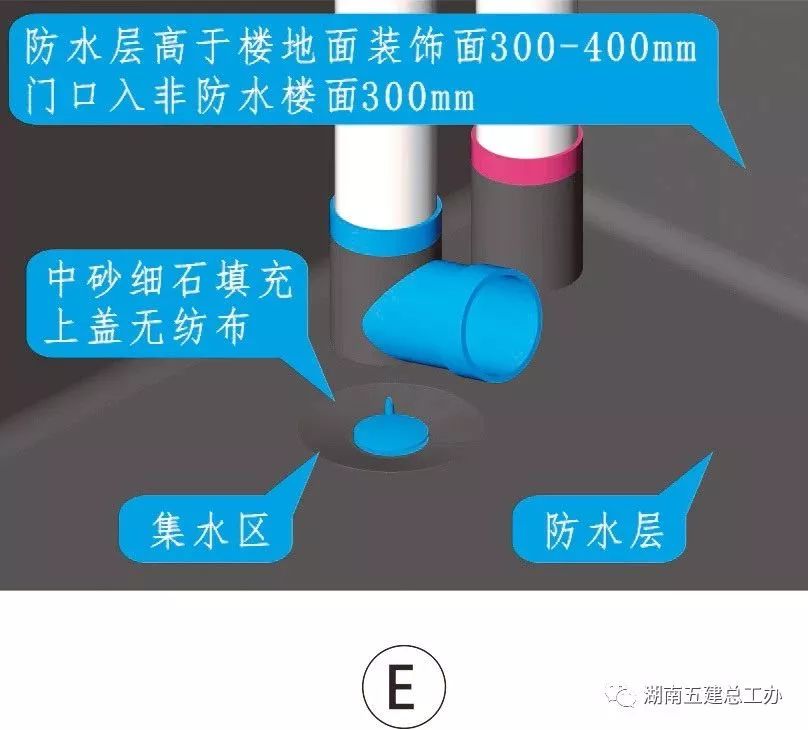

A groove shall be reserved around the pipe and embedded with waterproof ointment.

The direction between each layer shall be vertical, and the total thickness shall not be less than 1.5mm.

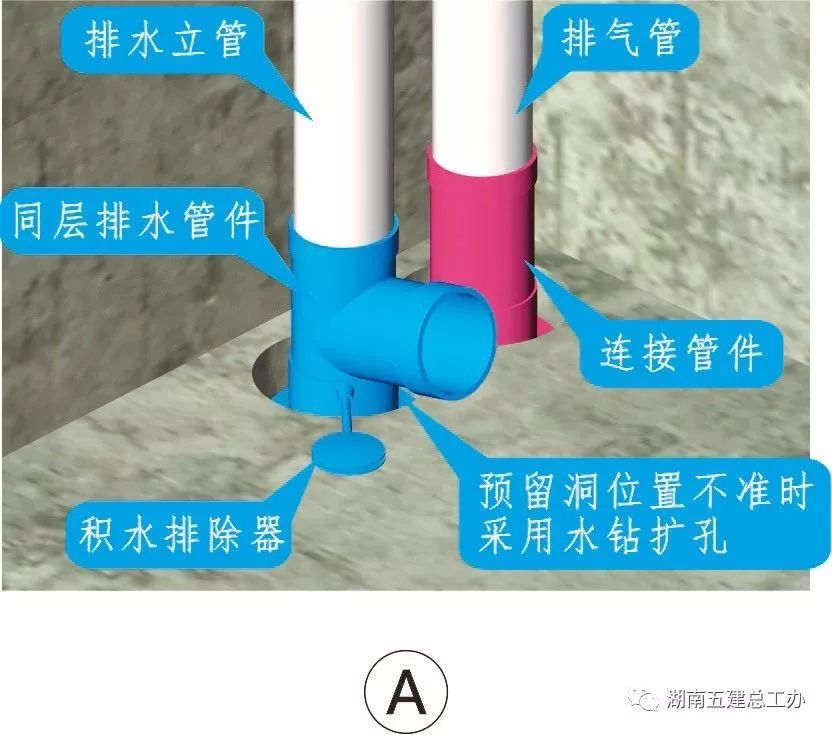

There shall be a water stop structure around the pipe section passing through the floor, and the bottom of the water collector of drainage pipe fittings on the same floor shall be flat on the structural plate surface, so as to ensure the smooth discharge of water in the waterproof leveling layer, waterproof layer and filling layer.

After the main body concrete and measurement work are completed, the hole wall mortar and transparent adhesive tape can be cleaned, the hole wall shall be roughened with handheld equipment, and then fixed with shaped formwork.

The filling layer must be made of light materials.

Before hole formwork erection and screw hole repair, clean and flush the periphery of the hole to ensure that the periphery of the hole is clean and free of mortar and oil stain.

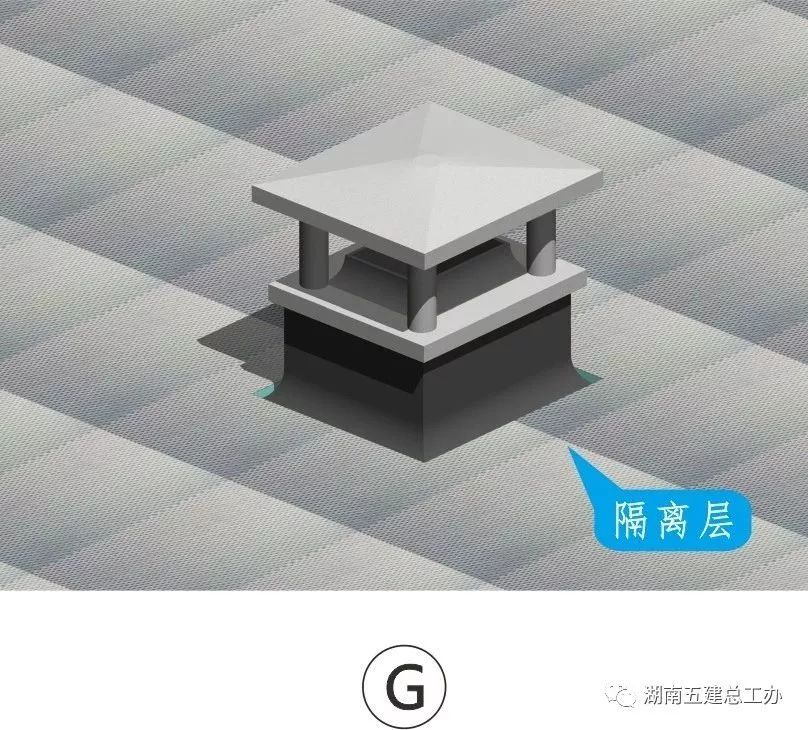

G.

The coating thickness of each layer shall be uniform and the direction shall be consistent.

special personnel shall be assigned to be responsible for the pouring of reserved holes and screw holes of external wall masonry and concrete wall, and supervise the whole process of hole repair.

After the hole wall is wet, tamp it in layers with slightly expanded fine aggregate concrete higher than the original design grade; V-shaped groove shall be reserved around the upper screw, and the surface shall be plastered and polished before the final setting of fine aggregate concrete.

2、 Floor construction and tunnel construction technological process Process key points a.

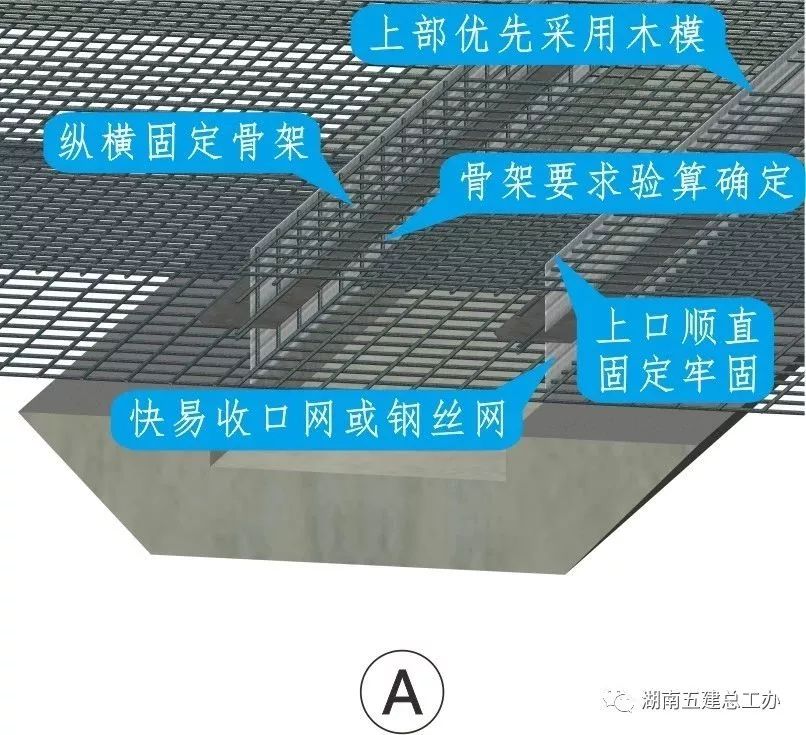

structural column construction technological process Process key points A.

The tenon shall be 60mm out, and the height of each horse tooth tenon shall not exceed 300mm.

Before acceptance, the mortar scattered on the column base and ash accumulation table during masonry shall be cleaned, and the sponge adhesive strip shall be pasted at the junction of column and wall; After self inspection, please ask the supervisor for acceptance and record for the record.

C.

In this process, the fine aggregate concrete and cement mortar are added with expansion agent and waterproof agent.

Twenty four hours after the concrete pouring of the floor slab, open the cover plate of the embedded bucket, release the fixing piece and lift it out of the embedded bucket; When the flat die is removed, the fixed piece shall be recovered in time for turnover.

F.

During floor concrete pouring, the floor management personnel shall take targeted care of the embedded barrel to avoid the direct contact of the pouring and vibrating equipment with the embedded barrel, resulting in the offset or deformation of the embedded barrel.

The fine aggregate concrete pouring in the holes of formwork erection must be vibrated with a small vibrator and shall not be replaced by a simple way.

If there is no double-layer reinforcement at the reserved hole, the double-layer annular reinforcement steel shall be welded into a skeleton.

If the large edge of the hole is greater than 100mm, the formwork must be erected for pouring.

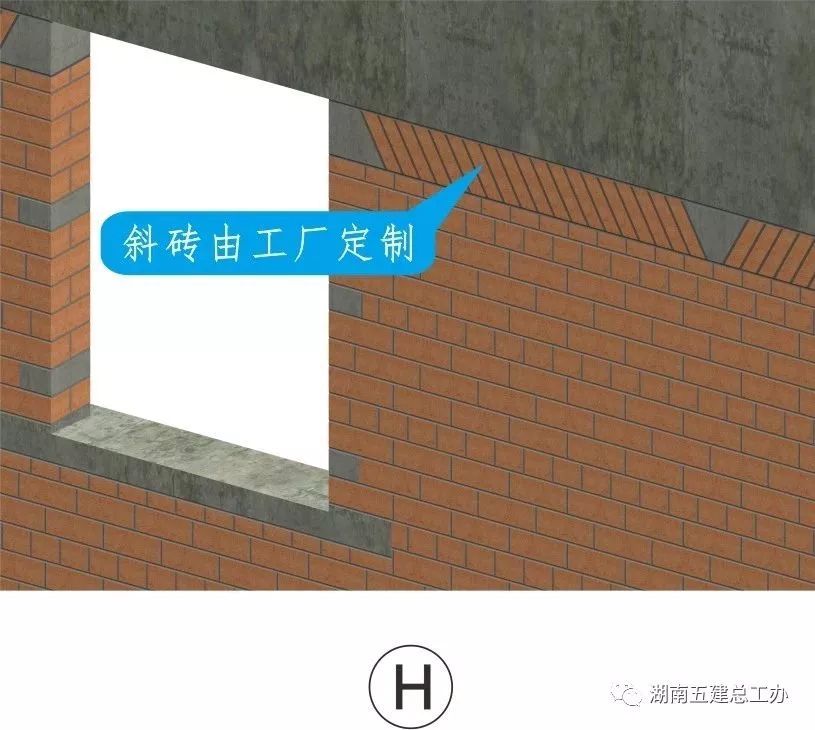

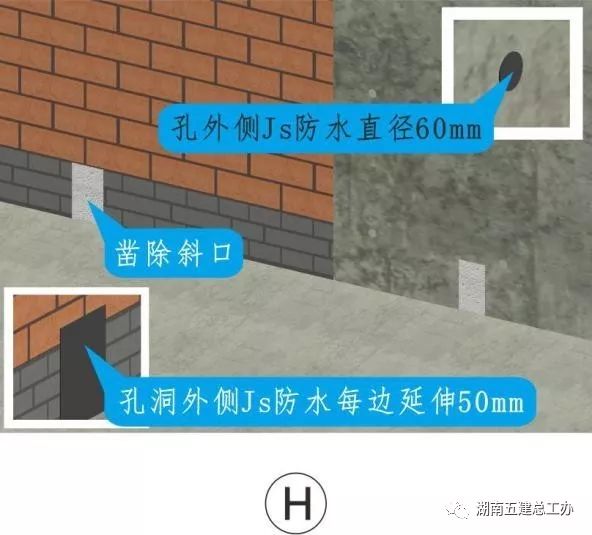

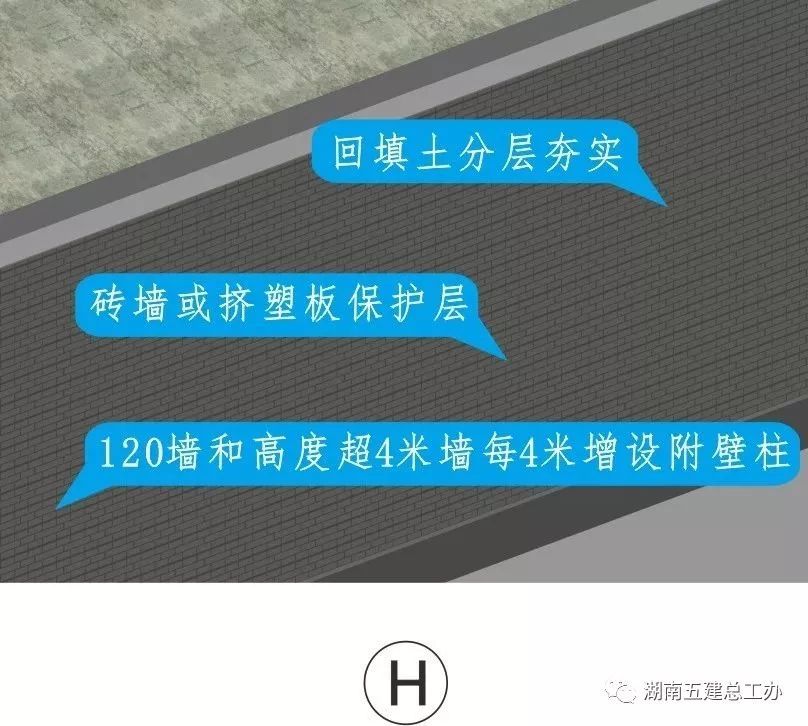

H.

The double-layer annular reinforcement around the hole shall be uniformly processed and manufactured in the reinforcement processing area.

The formwork of structural column shall be cleaned with sponge rubber strip without residue; The pouring mouth shall be carefully chiseled and polished in place, and the surface shall be flat without coarse aggregate pits.

3、 Repair of exterior wall holes technological process Process key points A.

The horse tooth tenon shall retreat first and then enter.

The leveling course shall be plastered and polished twice, and the slope shall be towards the ponding collection area.

The slope of the ground protective layer of the finished product effect building is obvious to the floor drain outlet, there is no ponding, sand and ash on the surface, and the waterproof ointment caulking around the pipe is full and smooth.

In order to prevent cracking, alkali resistant mesh cloth can be set in the wall protective layer for reinforcement.

Before the decorative surface layer of the floor of the residential building, a coating waterproof layer shall be made on the protective layer to form a composite waterproof layer with the civil waterproof layer.

H.

C.

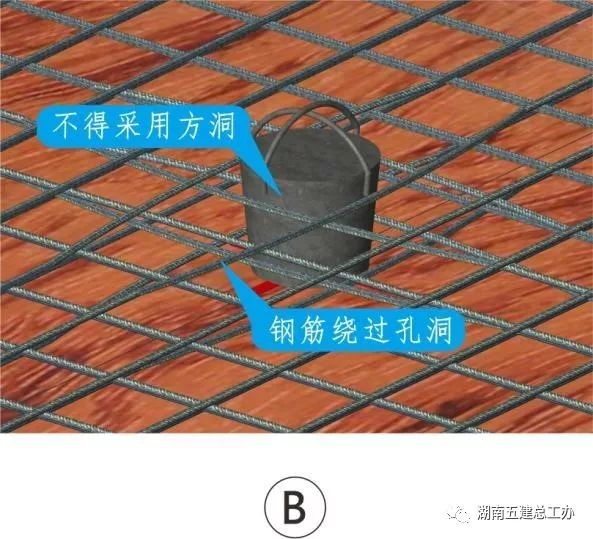

Due to the small size of pump pipe and measuring hole, the floor reinforcement here is not cut off, and the method of bending around the hole is adopted; Larger holes shall be treated according to the design requirements.

At least 80% of the formwork shall be new without peeling and loose edges; Clean the formwork surface and apply release agent before formwork erection; The split screw shall be used for fixing, and the tension shall be appropriate, and no holes or holes shall be left on the wall.

After 2 days of formwork removal, manually chisel the pouring inclined mouth and grind it flat.

D.

There is no obvious connection mark between the vertical flanging waterproof protective layer and the wall waterproof mortar, and the protective layer is free of cracks, clean and clean without pollution..

G.

After the base course is fully coated with cold primer oil, the waterproof layer shall be painted on the large surface.

H.

E.

the lower diameter of the conical measuring hole of the floor is 150mm, the upper diameter is 180mm, the lower diameter of the conical pump pipe hole is 220mm, and the upper diameter is 250mm; Position according to the main control line and fix it after review.

Before the leveling course, the defects of the base course shall be repaired with waterproof mortar, and the plain cement slurry interface shall be treated after cleaning.

The external wall screw grouting micro expansion waterproof cement mortar has no shrinkage cracks with the matrix, the size and color of the surface round cake are consistent, and there are no pollutants such as cement slurry around the hole.

During pouring, manual feeding and small electric vibrator shall be used for layered (300mm) vibration, and other simple vibration methods shall not be used instead.

H.

key points of waterproof process flow of drainage toilet on the same floor A.

D.

The formwork shall not be loosened or removed within 24 hours after the hole concrete is poured.

C.

G.

After the leveling layer is completely dry and cleaned, apply a coating additional layer around the pipe root passing through the floor and around the wall root, and add glass fiber cloth in the waterproof additional layer.

The formwork loosening and removal time shall be strictly controlled to avoid premature damage to the surface of the structural column, resulting in pitted surface of the column.

The finished product effect is that the masonry and concrete wall holes are densely poured with fine aggregate concrete without honeycomb and pitted surface, the thickness of JS is uniform, the surface is free of cracks, and the pouring opening is clean and flat without coarse aggregate pits.

Mortar shall be poured to the floor in time, and the embedded box and loose objects around the hole shall be chiseled off.