9.

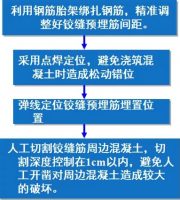

1) before binding the horizontal reinforcement, draw a positioning line on the adjacent column body, and the starting position of the positioning line shall be consistent with the spacing.

① the thickness of shear wall reinforcement protective layer in the design description and specification drawings is unclear, and the construction is arbitrary; ② Cushion blocks are not set as required or the number of cushion blocks is insufficient; ③ Ladder reinforcement is not set as required, and there are no effective positioning measures for longitudinal reinforcement; ④ The on-site quality monitoring of management personnel is not in place.

If concrete cushion block is used, binding wire shall be embedded during cushion block fabrication to facilitate binding and fixation.

6.

During the binding, the iron wire at adjacent binding points shall be buckled in an eight shape to avoid the deflection and deformation of reinforcement mesh; 3) The on-site management personnel shall strengthen the quality inspection and control of line drawing positioning and binding points to avoid random binding without line drawing or loose binding.

The longitudinal reinforcement of the shear wall is offset and the spacing between internal and external reinforcement is uneven 1) after accurate setting out, draw the position line at the position of the shear wall and fix the positioning reinforcement to ensure the accurate position of the longitudinal reinforcement when inserting reinforcement into the shear wall; 2) For the joint of beam, column and wall with small space, pay attention to timely correct and adjust the position of reinforcement affected by impact during concrete pouring.

The axis of electroslag pressure welding joint is offset or the reinforcement is bent ① the end of the reinforcement is not straight, the blanking of the reinforcement head is not flat, and the clamping in the fixture is not straight or inclined; ② The fixture has been worn for a long time, resulting in the non concentricity of the upper and lower reinforcement, and the difference between the diameters of the upper and lower reinforcement is too large; ③ Excessive force during preloading causes the upper reinforcement to shake and shift; ④ The lower reinforcement is not positioned and tilts or shakes during welding; ⑤ After welding, the clamp is loosened prematurely, and the joint is not cooled enough to tilt the upper reinforcement.

When binding the reinforcement, strictly control the position according to the positioning line; 2) During the binding of horizontal reinforcement, pay attention to fasten the intersection points of all reinforcement without missing binding.

The diameter of the horizontal reinforcement is the same as that of the horizontal reinforcement of the wall, with a length of – 2mm of the wall thickness.

common quality problems of shear wall reinforcement construction main causes 1.

After the concrete is hardened, the position of reinforcement with serious deviation shall be corrected according to the ratio of 1:6; 3) The ladder reinforcement shall be set in strict accordance with the requirements.

3.

During cushion block binding, the head of binding wire shall face the interior of the component to avoid rust spots; 2) The ladder reinforcement shall be set in strict accordance with the requirements.

The thickness of shear wall reinforcement protective layer is insufficient.

The longitudinal reinforcement of shear wall is offset, and the spacing between internal and external reinforcement is uneven ① the bottom reinforcement at the junction of beam, column and wall is dense, the space is insufficient, and the longitudinal reinforcement cannot be fixed in the design position; ② The concrete is impacted during pouring and is not adjusted in time, resulting in the deviation of joint reinforcement from the design position; ③ Ladder reinforcement is not set as required, and the spacing between inner and outer reinforcement is lack of effective control measures; ④ There are loopholes in the on-site supervision of the management personnel, and the construction personnel are not required to take technical measures to ensure the accurate positioning of the reinforcement in time.

Click the blue word above to follow us 01 Common quality problems and main cause analysis problems and cause analysis table No.

1) when blanking the reinforcement, the requirements of the anchorage length under different conditions shall be considered to avoid insufficient blanking length; 2) The horizontally distributed reinforcement of the shear wall shall extend to the wall end and be cut off after bending inward for 10 days, where D is the diameter of the horizontally distributed reinforcement; 3) When there is a wing wall or corner wall at the end of the shear wall, the horizontally distributed reinforcement on both sides of the inner wall and the horizontally distributed reinforcement on the inside of the outer wall shall extend to the outside of the wing wall or corner wall, and shall be cut off after bending horizontally to both sides, and the horizontal bending length shall not be less than 15d; 4) At the corner wall, the horizontally distributed reinforcement outside the outer wall shall be bent into the wing wall at the outer corner of the wall end and overlapped with the horizontally distributed reinforcement outside the wing wall, with an overlapping length of 1.2la; 5) For the shear wall with frame, the horizontal and vertical distributed reinforcement should penetrate the column and beam respectively or be anchored in the column and beam; 6) Before construction, the site management personnel shall clarify the anchoring requirements of the horizontal reinforcement of the shear wall, and timely correct the wrong anchoring method and insufficient anchoring length during the on-site construction..

The thickness of protective layer of shear wall reinforcement is less than 1) plastic cushion block or concrete cushion block shall be set as required.

It shall replace the wall reinforcement in situ, with a spacing of about 1500mm.

The lap length of horizontal reinforcement of shear wall is insufficient and the joint position is wrong ① the blanking length of horizontal reinforcement is insufficient; ② The horizontal reinforcement is not overlapped according to the design and specification requirements; ③ The horizontal reinforcement joints are not staggered according to the design and specification requirements; ④ The site management personnel do not understand the binding requirements of shear wall reinforcement clearly, and the quality control is difficult to be in place.

4.

If the lap is welded, it shall comply with the code for welding and acceptance of reinforcement; 4) Before construction, the site management personnel shall clarify the binding requirements of shear wall reinforcement, and timely correct the insufficient lap length and incorrect joint connection position during on-site construction.

5.

2.

4.

1) the requirements of lap length shall be considered during reinforcement blanking to avoid the occurrence of insufficient blanking length; 2) The lap length of horizontally distributed reinforcement of shear wall shall not be less than 1.2la (LA is the anchorage length of reinforcement); 3) The clear spacing along the horizontal direction between the lap joints of the horizontally distributed reinforcement in the same row and between the lap joints of the upper and lower adjacent horizontally distributed reinforcement shall not be less than 500mm.

5.

The end shall be polished, and the protruding parts of the reinforcement on both sides and ends shall be painted with antirust paint; 4) The management personnel shall strengthen on-site supervision and management, especially at the beginning of column reinforcement binding and concrete pouring, and timely guide the construction personnel to review and adjust the column position.

02 Detailed explanation 1.

The arrangement of shear wall hooks is wrong or the quantity is insufficient ① the shear wall hooks are skewed, resulting in the smaller spacing between the inner and outer reinforcement of the wall; ② The draw hook is not arranged as required, especially the quincunx draw hook; ③ The site management personnel do not understand the layout and binding requirements of the steel hook of the shear wall clearly, and the quality control is difficult to be in place.

The reserved reinforcement of shear wall is lack of protection and the end of reinforcement is polluted ① during concrete pouring, effective protection measures are not taken for the reinforcement at the upper part of the concrete surface, resulting in reinforcement pollution; ② The protective cap is not installed in time after the joint reinforcement is reserved, and the reinforcement is exposed to the air for a long time, which is polluted or rusted; ③ No special person is responsible for the protection of reserved reinforcement, and there are missing links in quality control.

The horizontal reinforcement spacing of the shear wall is uneven.

8.

The diameter of the horizontal reinforcement is the same as that of the horizontal reinforcement of the wall, with a length of – 2mm of the wall thickness.

3.

The lap length of horizontal reinforcement of shear wall is insufficient and the joint position is wrong.

Figure 32.3 ‑ 3 sufficient cushion blocks are arranged outside the shear wall figure 32.3 ‑ 4 ladder reinforcement is set in the shear wall to control the reinforcement spacing.

The welding package of electroslag pressure welding is uneven ① the end of reinforcement is uneven; ② Uneven flux filling and poor reinforcement melting effect; ③ After welding, the fixture is loosened prematurely and the melting amount of reinforcement is less; ④ After welding, the construction personnel did not timely remove the external residue of the welding package, check the welding package quality, the construction procedure was incomplete, and there were loopholes in the monitoring of the management personnel.

It shall replace the wall reinforcement in situ, with a spacing of about 1500mm.

The end shall be polished, and the protruding parts of the reinforcement on both sides and ends shall be painted with antirust paint; 3) Before construction, the site management personnel shall strengthen the technical disclosure, clarify the thickness of reinforcement protective layer, cushion block and ladder reinforcement arrangement method for different parts on site, and strengthen the quality supervision in the process of shear wall reinforcement binding.

7.

The anchorage method of the horizontal reinforcement end of the shear wall is wrong or the anchorage length is insufficient ① the blanking length of the horizontal reinforcement is insufficient; ② During the construction of horizontal reinforcement, the constraint components at the inner edge of the wall are not considered; ③ The site management personnel do not understand the anchorage requirements of steel horizontal reinforcement of shear wall clearly, and the quality control is difficult to be in place.

The diameter of the vertical reinforcement of the ladder reinforcement shall be one model larger than that of the vertical reinforcement of the wall.

The horizontal reinforcement spacing of shear wall is uneven ① the horizontal reinforcement is not marked for positioning before binding; ② The number of binding points of horizontal reinforcement and longitudinal reinforcement is insufficient, and there is downward deflection in the middle; ③ The on-site quality monitoring of management personnel is not in place.

Illustration 32.3 ‑ 1 ladder reinforcement for shear wall illustration 32.3 ‑ 2 ladder reinforcement for shear wall 2.

The diameter of the vertical reinforcement of the ladder reinforcement shall be one model larger than that of the vertical reinforcement of the wall.

The anchorage method of the horizontal reinforcement end of the shear wall is wrong or the anchorage length is insufficient.