8 before pouring, the formwork shall be watered and wetted, and the garbage shall be cleaned up.

Within 12h after the completion of concrete pouring, special personnel shall be arranged for maintenance immediately.

19 the insertion range of the vibrating rod should be 250mm.

9 before pouring, check whether the outer frame is erected 1.5m higher than the finished surface of the layer of concrete, and hang dense mesh mesh.

It is recommended to send a special person to be on duty next to the tank car.

3.

For large holes, they shall be chiseled, watered and wetted, and then poured with concrete one level higher than the original concrete· .

Let’s take a look at how they control the process? 1 before concrete pouring, calculate the concrete volume 3 days in advance and report it to the commercial mixing station.

If there is secondary decoration, the surface shall be roughened.

At this time, the shear wall shall be poured first.

26 cover with film for moisturizing after roughening treatment.

16.

When the stairs are about to be poured, communicate with the mixing plant in advance.

Especially the anchoring position of the floor reinforcement on the beam.

After the concrete pouring of the shear wall in one place is completed, when the shear wall in another place needs to be poured, the outlet of the concrete pump pipe shall be quickly packed with gunny bags.

There is only one remedial measure behind it, that is, spray maintenance for a month, wasting manpower and material resources).

Do not vibrate after pouring to 200mm-300mm higher than the shear wall.

Concrete pouring construction process is very important, but it is often easy to be ignored.

The slump should be controlled between 160mm-180mm, and the spot check of concrete should be between 1 / 4-3 / 4 of the tank truck.

After the shear wall concrete is poured, do not vibrate with a vibrating rod at this time, and continue to pour the shear wall concrete.

Quickly pour the concrete of beam and slab.

When the shovel is shovel into the shear wall, it will be about 100mm thick to prevent rotting roots) 6 concrete vehicle must be reversed more than 20S before unloading the concrete into the ground.

Do not lift up when pouring concrete.

This is because the pouring time is long, people have fatigue period and are easy to slack off.

The vibrating rod should vibrate until the surface is flat, there is slurry flooding on the surface, and there is no bubble.

Different concrete cannot be mixed together.

The white cement and black cement with a volume ratio of 1:3 are treated with an appropriate amount of 107 glue.

Many formwork collapse events are caused by the ground pump pipe touching the formwork).

28 after formwork removal, if a small amount of honeycomb and pitted surface are found locally.

23 during concrete pouring, reinforcement workers, carpenters and electricians must have special personnel on site.

20 during pouring, the elevation must be well controlled through the 50 line and pull through line previously marked on the shear wall.

13.

7 check the concrete slump every 3 vehicles.

It is strictly prohibited to complete the pouring at one time.

17 when the pouring height of shear wall and column exceeds 2m, layered pouring and layered vibration must be adopted.

18.

Reinforcement worker: pay attention to the reinforcement of shear wall and beam, and do not stick to the surface reinforcement of formwork and slab during concrete pouring.

Prepare 4 vibrators, 3 for on-site use and 1 for emergency use.

When the wall column is vibrated twice, use 50 vibrator to vibrate while vibrating, and use 30 or 20 vibrator or manual hammer to hammer the formwork (two workers hammer at both sides of the wall column at the same time, from bottom to top, with a hammer spacing of 200mm) for secondary vibration, so as to prevent the generation of surface bubbles, honeycombs, pitted surfaces and rotten roots.

21 it is forbidden to add water to the tank car.

When the concrete of beam and slab is poured to the shear wall, vibrate together, and the concrete of shear wall and beam and slab can be well separated.

Transport the concrete with small slump for pouring (the stairs are inclined, the slump is large, and the water in the concrete is easy to flow away).

When pouring the elevator shaft, it must be poured in a rotary way, otherwise the formwork is easy to explode.

Therefore, it is very important to master the key points of pouring, as long as the key points are well controlled.

In the first 7 days, if the maintenance is not in place, the strength of the concrete is very difficult to achieve the design standard.

14 If the concrete models of shear wall and beam slab are different, the requirements of the owner and the supervisor are relatively strict.

Electrician: pay attention to the vibration of 24 floors after power failure.

5 the first vehicle concrete is the same cement mortar as the original mix proportion (first, it is inserted into the large iron bucket or the special cement mortar tool.

It is recommended to vibrate 25 floors with a flat vibrator.

Carpenter: pay attention to the occurrence of mold running and mold explosion.

15 when the reinforcement at the beam column junction is too dense, the vibrating hole shall be reserved during binding.

27.

Personnel arrangement: 6 persons for vibration (1 person for vibrator and 1 person for vibration), 2 persons for concrete leveling, 2 persons for receiving and polishing, 1 person for unloading port of tank truck (responsible for taking out large stones in concrete), 1 person for holding concrete discharge pipe, 1 person for on-site coordination, and 1 person for tank truck of 4 concrete truck to keep rotating during transportation.

Assign special personnel to control the elevation and flatness of the concrete surface around the shear wall and the root of the wall column within 3mm, so as to facilitate the formwork closing of the shear wall in the later stage.

Maintenance for at least 7 days (maintenance is very important.

22 pave the berm in advance before pouring concrete.

10 check whether it is necessary to lift the tower crane 11 check whether the ground pump pipe touches the formwork of the floor slab (it must not touch the formwork.

Prevent mixing of shear wall concrete and beam slab concrete.

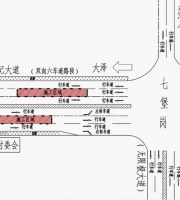

12 the pouring sequence is to pour the shear wall first, then the beam slab, and then the stairs when the beam slab is half poured.

2.