The distance from the edge of end fastener cover plate to the rod end shall not be less than 100mm.

(4) The installation of wall connecting parts shall be carried out simultaneously with the erection of scaffold and shall not lag behind the installation.

When it is difficult to set there, other reliable measures shall be taken to fix it.

Common problem 7: the setting position of small cross bar deviates from the main node, and small cross bar is omitted at some main nodes.

A transverse horizontal bar must be set at the main node, which is fastened with right angle fasteners and is strictly prohibited to be removed.

Common problem 2: the height difference deviation of longitudinal horizontal pole is large (the height difference of longitudinal horizontal pole on site exceeds 100mm).

common problems of cantilever scaffold structure 1 Common problem 1: the verticality deviation of vertical pole is large (the verticality deviation of vertical pole on site is 150mm).

Treatment measures: when the vertical pole of scaffold is disconnected at the place with overhanging balcony and bay window plate, the disconnected scaffold shall be reinforced with reference to the scaffold reinforcement measures at the door opening given in the specification.

When overlapped and extended, the overlapping length shall not be less than 1m, and shall be fixed with not less than 2 rotating and fasteners.

The specification stipulates that the length of the ends of each bar protruding from the edge of the fastener cover plate shall not be less than 100mm.

(2) The diagonal bridging rod shall be fixed on the extended end or vertical rod of the transverse horizontal rod intersected with it with rotating fasteners, and the distance from the center line of rotating fasteners to the main node shall not be greater than 150mm.

The materials shall be stacked more than 3m away from the distribution box, and there shall be a smooth channel.

Common problem 10: the cantilever length of the cantilever section steel of the cantilever scaffold is greater than its anchorage length, and most of the U-shaped reinforcement pull rings of the anchored section steel cantilever beam are single, and the wooden plug at the U-shaped reinforcement pull ring of some anchored section steel cantilever beams is missing.

8.

Common problem 5: the spacing of upright rods is too large, some upright rods are not continuously set, and reinforcement treatment is not carried out (in the process of site construction, the spacing of vertical poles is set at random, and similar problems exist at the longitudinal horizontal poles).

Common problem 3: the joint position of longitudinal horizontal pole is in the middle of span (the position of joints of horizontal and vertical poles on site is extremely random).

I.

The specification stipulates that: (1) the height of primary cantilever scaffold shall not exceed 20m.

7.

(2) The profile steel cantilever beam should adopt the profile steel with biaxial symmetrical section.

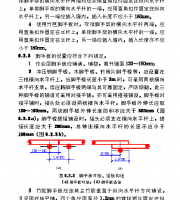

The specification stipulates that: (1) the joints of two adjacent longitudinal horizontal poles shall not be set in the same or the same span; the staggered distance of two adjacent joints in the horizontal direction of asynchronous or different spans shall not be less than 500mm; the distance from the center of each joint to the nearest main node shall not be greater than 1 / 3 of the longitudinal distance, as shown in the following figure: (2) When the vertical pole is lengthened by butt joint, the butt fasteners of the vertical pole shall be staggered, and the joints of two adjacent vertical poles shall not be set in the synchronization.

In conclusion, there shall be no two joints in the synchronous same span of the scaffold 。 4.

The model and anchor of the cantilever steel beam should be determined according to the design, and the section height of the steel beam should not be less than 160mm.

The inclination angle between the inclined rod and the ground should be 45 ° ~ 60 °.

Prevention: power distribution Materials, especially inflammables, are not allowed to be stacked around the box.

(4) the cantilever end of section steel cantilever beam shall be provided with a positioning point that can reliably fix the scaffold pole and steel beam, and the positioning point shall not be less than 100mm from the end of cantilever beam.

The wooden plug is missing and the section steel is missing The anchorage length is less than its cantilever length The U-shaped anchor bar is a single one.

The specification for the dislocation of diagonal bridging diagonal bracing diagonal bracing without connection between diagonal bracing and vertical pole stipulates that: (1) the extension of diagonal bridging diagonal bracing shall be overlapped or butt jointed.

(3) The U-shaped reinforcement pull ring or bolt used for anchoring shall be formed by cold bending.

Common problem 8: there are many sundries accumulated on the scaffold and they are not cleaned in time, resulting in potential safety hazards to the construction personnel below.

(5) When the anchoring position is set on the floor, the thickness of the floor shall not be less than 120mm.

If the thickness of the floor is less than 120mm, reinforcement measures shall be taken.

6.

Hazards: in case of emergency, the access is inconvenient and the power supply cannot be disconnected in time; the maintenance personnel are not conducive to operation.

Refer to two drawings: the scaffold lifted from the 16th floor is missing all the wall connecting parts from bottom to top at the North staircase, and the setting position of the wall connecting parts is very random.

(6) The cantilever beam spacing shall be set according to the longitudinal distance of the vertical pole of the cantilever frame, one for each longitudinal distance; the structure of the section steel cantilever scaffold is shown in the following figure: II.

The specification stipulates that: (1) the wall connecting parts shall be set close to the main node, and the distance from the main node shall not be greater than 300mm.

10.

Common problem 9: the diagonal bridging bar is misplaced, And the diagonal bridging rod is not connected with the vertical rod or horizontal rod of the frame body with fasteners.

FAQ 4: small cross bar The length of the ends of some longitudinal horizontal bars and wall connecting members protruding from the edge of the fastener cover plate is less than 100mm (there are many such problems on site, which need to be rectified).

(2) It shall be set from the longitudinal horizontal bar in the first step of the bottom layer.

The diameter of the U-shaped reinforcement pull ring or anchor bolt anchoring the profile steel cantilever beam should not be less than 16mm.

The small cross bar deviates from the main node, and the small cross bar is not set according to the specifications: (mandatory provisions).

The tail end of the cantilever beam should be fixed on the reinforced concrete beam slab structure at two or more places.

The specification stipulates: 3.

Treatment measures: the management personnel shall track and check in time and clean up the potential safety hazards in time.

The specification stipulates: 2.

(3) The width of each cross bridging shall not be less than 4 spans, and shall not be less than 6m.

Common problem 6: the setting method of wall connecting parts is inconsistent with the specification, and the quantity is too small , and the site is seriously missing, It brings great potential safety hazards to the scaffold (this problem must be rectified as soon as possible).

5.

(3) diamond arrangement shall be preferred, or square and rectangular arrangement shall be adopted, generally “two steps and three spans”.

Common problem: use the plastic knife switch (HK8) eliminated by the state..

The gap between the U-shaped reinforcement pull ring, anchor bolt and section steel shall be wedged with steel wedge or hardwood wedge.

The staggered distance between the two separated joints of one vertical pole in the synchronization shall not be less than 500mm in the height direction; the distance from the center of each joint to the main node shall not be greater than 1 / 3 of the step distance.

9.

Common problems of temporary power consumption: too many materials are stacked around the distribution box, which is inconvenient for access and is not conducive to operation.