The axis deviation at the joint shall not be greater than 0.1 times the diameter of the reinforcement and not greater than 2mm; The height of welding package shall not be less than 4mm; The bending angle at the joint shall not be greater than 3 degrees; Problem Description: 1.

Exposed reinforcement at the bottom of concrete structure slab and insufficient protective layer.

The processing hook of wall column stirrup does not meet the specification requirements; Correct method: 1.

During installation, it shall be ensured that the top and bottom are concentric; Problem Description: 1.

The height of the beam web is too high and the split screw is not used for reinforcement; Correct method: 1.

The height of the free end of the cantilever of the turnbuckle scaffold shall not be greater than 650mm; Problem Description: 1.

The beam with web height greater than 450 mm shall be reinforced with split screw to avoid formwork expansion and deformation at the beam in the later stage; Problem Description: 1.

The cushion block of reinforcement protective layer of concrete structure wall is not set enough, and there are cracks and exposed reinforcement; Correct practices: 1.

The distance between the starting reinforcement of wall column and the ground shall not be greater than 50mm; Problem Description: 1.

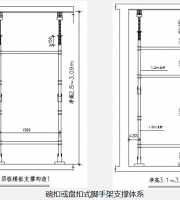

The bottom of the vertical rod of the formwork support frame shall be provided with a skid and a base, and the top shall be provided with an adjustable support.

The formwork support frame is 200mm above the ground at the bottom of the vertical pole, and the sweeping pole shall be set along the vertical and horizontal direction according to the procedure of vertical, lower and horizontal; Problem Description: 1.

The height of the free end of the cantilever of the turnbuckle scaffold is too high; Correct practice: 1.

The height of cantilever free end of steel pipe fastener scaffold is too high; Correct practice: 1.

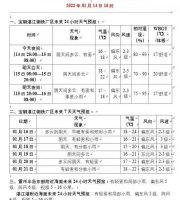

Problem Description: 1.

The fixed spacing of aluminum mold back plate pins is too large, which does not meet the specification requirements; Correct practice: 1.

The center spacing of the secondary keel of the roof formwork is 200mm ~ 250mm and evenly arranged; Problem Description: 1.

Stirrup reinforcement shall be set for slab reinforcement to effectively ensure the position of slab reinforcement and the thickness of protective layer; Problem Description: 1.

The shear wall is equipped with 6 pairs of pull screws, the bottom is 200mm from the ground, the top is 300mm from the top plate, and the middle spacing is controlled at 400mm-450mm.

The removal of concrete structural slab support system shall meet gb5066-2011 (formwork removal report); Problem Description: 1.

The formwork reinforcement method at the junction of beam and shear wall at the construction portal is unreasonable, and there is staggered platform; Correct method: 1.

The main beam stirrup at the junction of primary and secondary beams shall be set through; Problem Description: 1.

The welded joints of the longitudinal stressed reinforcement of the column are in the same horizontal plane; Correct method: 1.

When setting diagonal bracing, the spacing of wall diagonal bracing shall not be greater than 2000mm, and the length of wall diagonal bracing greater than or equal to 2000mm shall not be less than 2; Problem Description: 1.

Processing hook angle of wall column stirrup: 135 °, hook length: min (10d, 75mm); Problem Description: 1.

The specification requires that the extension length of top screw rod shall not be greater than 300mm; Problem Description: 1.

Problem Description: 1.

Fixing Socket Angular End Nail Plate

Problem Description: 1.

The main beam stirrup at the junction of primary and secondary beams is not set through; Correct method: 1.

The welded joints shall be staggered in strict accordance with the specification requirements, and the staggered length shall not be less than 35d and not less than 500mm; Problem Description: 1.

The screw shall not extend beyond the top of the steel pipe by more than 200mm, and the gap between the outer diameter of the screw and the inner diameter of the column steel pipe shall not be more than 3mm.

Double layer and two-way reinforcement shall be set around the reserved hole greater than 300mm; Problem Description: 1.

The setting of fixed diagonal bracing of shear wall is insufficient; Correct practice: 1.

The pin spacing should not be greater than 300mm; Problem Description: 1.

The number of effective threads of reinforcement straight thread does not meet the specification requirements; Correct practice: 1.

The reinforcement method of shear wall formwork does not meet the requirements; Correct method: 1.

The reserved hole larger than 300mm is not reinforced according to the specification; Correct method: 1.

The exposed thread buckle at the connecting joint of straight thread sleeve exceeds the specification requirements; Correct method: 1.

The tenon of the construction joint of the staircase on the operation floor shall return up to 1 / 3 or the beam support..

The height of the free end of the cantilever of the turnbuckle scaffold shall not be greater than 650mm; Problem Description: 1.

Correct practice: 1.

Set vertical and horizontal ladder reinforcement for shear wall to effectively control reinforcement spacing and positioning; Problem Description: 1.

Use a cutting machine to cut the reinforcement, ensure that the straight thread stripping end is flush, and set a protective cap at the joint position; Problem Description: 1.

The specification requires that the exposed wire buckle is 1.5p ± 0.5.

Some base plates are missing at the bottom of the formwork support in the floor; 2.

The beam bottom shall be supported separately, and the beam formwork at the junction of beam and shear wall formwork shall be made into shaped L-shaped formwork, and the secondary keel shall be pressed at the vertical joint of wall and beam formwork.

Earthwork backfilling shall be filled and compacted, and the layered backfilling shall meet the requirements of 200-300mm; Problem Description: 1.

Problem Description: 1.

The tenon of the construction joint of the stairs on the operation floor does not return up to 1 / 3; Correct method: 1.

The height of the free end of the cantilever of the turnbuckle scaffold is too high; Correct practice: 1.

The welding package of electroslag pressure welding is not full and eccentric; Correct practice: 1.

The exposed length of the top screw of the inner bent u support does not meet the specification requirements of 200mm; Correct method: 1.

The effective thread of straight thread connection shall be calculated according to the sleeve size and specification, and the number of exposed threads shall be reserved; Problem Description: 1.

The concrete structural slab support system was removed in advance; Correct practice: 1.

The jacking extension length of formwork support pole exceeds the specification requirements; Correct practice: 1.

The spacing between the secondary keels of the top plate is uneven; Correct method: 1.

The end of the reinforcement of the straight thread sleeve connection joint is not cut flush and stripped, which affects the stress of the joint, and there is no protective cap at the reserved joint position; Correct method: 1.

The earthwork of the outer wall of the basement is not backfilled in layers, and there are garbage and stones; Correct practice: 1.

The distance between the starting reinforcement of wall column and the ground is too large, which does not meet the specification requirements; Correct method: 1.

Some base plates and sweeping rods are missing at the bottom of the formwork support in the floor, and the stability of the frame is insufficient; Correct practice: 1.

The height of the free end of the cantilever of the fastener scaffold shall not be greater than 500mm; Problem Description: 1.