Before this work, the DC system shall be switched and the two sets of DC systems shall be connected in parallel.

IV.

In order to prevent personnel from entering other operation panels by mistake, the working area and non working area are isolated by fence in the main control room, as shown in the figure below.

For this, special insulation baffle can be used to isolate the live part, and warning signs can be pasted for prompt, as shown in the figure below.

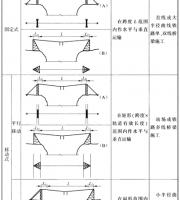

The main work contents of DC system overhaul of the station are shown in the figure below.

III.

05 optimize the allocation of resources.

construction difficulties and safety precautions for DC charging panel overhaul the main content of DC charging panel overhaul is to replace the monitoring module and charging module on DC charging panel.

4.

Disconnect the feeder air switch from the feeder terminal block.

Separate the base of the feed terminal block from the feed unit plug-in frame, and then pull out the feed plug-in frame unit for overall replacement.

However, if the DC bus behind the DC contact screen operates with electricity, it is very easy to cause accidents such as DC system short circuit, grounding and personal electric shock if safety isolation measures are not taken.

When replacing the feeder frame unit without power failure, it is necessary to transfer the DC load first, which is easy to cause DC voltage loss.

Taking the DC system overhaul of a 220 kV substation of the company as an example, this paper expounds the difficulties and safety precautions in the construction of “core cutting” transformation of two power, two charge and four feed DC system.

The advantage of this transformation method is that there is no need to replace the panel cabinet and feeder cable, which can greatly save investment and shorten the construction period, but there are also many difficulties and safety risks in the implementation process.

At the same time, two standby air switches are selected as the temporary space-time switches for load transfer on the left and right terminals respectively.

After verifying that the upper and lower voltages of the air switch are correct and the polarity is consistent, close the temporary air switch.

Source: e Dian security you, me and him..

A brief description of the “core cutting” transformation of the two power and two charge DC system refers to the replacement of all components on the DC screen without power failure to realize the renewal and upgrading of the DC system.

This work requires two people to cooperate in front of and behind the screen.

Before disconnecting the feeder plug-in frame unit, hang a special mechanical lock on the disconnected air switch to prevent false closing of the air switch.

The main content of DC feed panel is to replace the feed frame unit (including air switch, indicator light, Hall current sensor), meter, sampling module and insulation monitoring device.

construction difficulties and safety precautions of DC contact panel overhaul the main content of DC contact panel overhaul is to replace the meter, indicator and sampling module on DC contact panel.

At the same time, it is marked with the sign of “no closing, someone working” for warning.

Lead out the positive and negative wires of the two load transfer switches respectively and connect them to the left and right feed terminal blocks.

3.

The replacement steps of the feed plug-in frame unit are as follows: 1.

2.

Overall safety measures on site the work scope of this DC system overhaul only includes DC panels and cabinets (71p ~ 77p) in the main control room, as shown in the figure below.

5.

At this time, the DC load is transferred from two loads to the temporary air switch for power supply.

Short the positive terminal and negative terminal on the feed terminal strip on the left and right sides of the feed plug-in frame unit with short connectors respectively.

II.

This paper analyzes the construction difficulties and safety precautions of DC system overhaul in a 220 kV substation of the company, which can provide reference for DC professionals to complete the “core cutting” transformation of DC system, and further improve the transformation ability of DC system of the company.

Wear insulating gloves and stand on the insulating pad when taking out the battery pack insurance during switching operation to prevent personal electric shock accident when taking out the battery pack insurance; The battery fuse base is sheathed with a special insulating box and hung with a “no switching on” sign to prevent short circuit between the positive and negative poles of the battery and personal electric shock.