C130 concrete is prepared with steel fiber, which greatly increases the difficulty of pumping; 5.

Material localization.

The concrete shall meet the relevant index requirements of durability.

High requirements for slump retention performance, initial slump ≥ 250mm, initial expansion ≥ 700mm, 5-hour slump loss ≤ 20mm and expansion loss ≤ 50mm; 8.

After multiple selection and comparison, the final R & D results of the scientific research team can achieve multiple composite reinforcement effects such as compact filling effect, physical water reduction, pozzolanic activity and alkali excitation.

The vertical pumping height is 380m and the total length of pump pipe is more than 500m; 2.

If you do not want to miss the highlight of this official account, please set the public address of the construction technology as the star sign and click “collect”, “look at” and “Zan” at the end of the text, so that each new article will appear in the subscription list at the first time.

/ / official account official of WeChat / NOCITCE / WeChat changed the push rule because of the official account of WeChat.

How to pump such strong concrete has always been a difficult problem faced by researchers.

“The use of C130 ultra-high strength concrete can reduce the use of concrete, formwork and formwork reinforcement components, reduce the use of revolving materials and material consumption of the project, and help achieve the” double carbon “goal.” The relevant person in charge of the scientific research institute said that the scientific research institute will uphold the spirit of “sincerity”, give full play to its professional advantages, actively “build” new landmarks, and contribute to the high-quality development of the enterprise.

A 1 square meter C130 concrete component can stably carry 6500 family cars.

The initial setting time shall not be less than 15 hours and the final setting time shall not exceed 20 hours; 9.

It is reported that C130 is ultra-high strength concrete.

The scientific research institute insists on using the high-quality aggregate produced by local materials, which is more technologically guaranteed than the domestic technical route of mostly using river sand or river sand + machine-made sand to prepare concrete.

The relevant person in charge of the scientific research institute said that super high-rise, long-span and special-shaped structure buildings put forward higher requirements for the strength, durability and reliability of concrete.

The Android and iOS user operation is the same.

While summarizing and analyzing their own pumping experience of ultra-high strength concrete, the technical team of the Scientific Research Institute continues to tackle key technical problems.

The new slump and viscosity reducing water reducer and viscosity reducing ultra-fine powder are used to make C130 concrete have the viscosity of C40 concrete.

C130 manufactured sand concrete has high technical requirements.

Source: Luban alliance of construction engineering, etc.

If the original copyright owner disagrees.

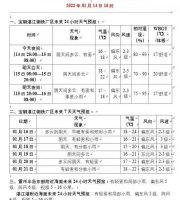

)The 380m ultra-high pumping test of C130 ultra-high performance steel fiber manufactured sand concrete was completed in Building 1 of country garden Guiyang center project, a key project in Guizhou Province, breaking the world record for the pumping height of all manufactured sand solid projects.

Click Set as star, The yellow star is the next official account.

Star setting: enter the official account homepage and click on the top right corner.

In this experiment, high-end testing and monitoring equipment and technical means such as sliding tube instrument are used to accurately obtain the difference of pumping resistance between C130 high-performance fiber manufactured sand concrete and ordinary concrete, so as to provide technical parameter reference for pump selection and pump pipe layout of similar super high-rise buildings.

(hereinafter referred to as “Research Institute”).

Ultra high strength, strength grade C130; 4.

High end equipment.

Technical points and difficulties: 1.

The copyright belongs to the original author and original source.

The scientific research institute promoted the development of the industry with the “four modernizations” of material localization, rationalization of collocation, innovation of proportion and high-end equipment, which not only solved the industry problems, but also added impetus to the “double carbon” goal.

The emptying time of inverted slump cylinder is less than 3 seconds, which can maintain the workability of concrete for more than 4 hours, It ensures that the concrete has the ability of ultra-high pumping above 400m.

The viscosity of concrete is high, so it needs to be adjusted to the viscosity of ordinary C30 concrete through proportion adjustment and admixture performance improvement.

Ratio innovation.

After hundreds of experiments and demonstrations, the scientific research team broke the performance limitations of various existing materials, continuously optimized the mix proportion through theoretical analysis, and finally realized the unity of high strength and pumping performance of manufactured sand.

The initial collapse emptying time is ≤ 3S, 3h collapse emptying time is ≤ 4S, and 5h collapse emptying time is ≤ 5S; 7.

Rationalization of collocation.

The innovative use of steel fiber materials in the mix proportion effectively improves the problems of high stiffness and insufficient toughness of high-strength concrete.

Prepared with pure machine-made mountain sand; 3.

Extremely low water binder ratio – the water binder ratio is less than 0.2, and mixing concrete is like glutinous rice balls; 6.

In December 6th, Guizhou Zhongjian architectural research and Design Institute Co., Ltd.