The whole process is efficient, convenient, intelligent and accurate.

With the Ministry of housing and urban rural development including the “measurement robot” into the “list” and promoting it nationwide, the construction to intelligent manufacturing has become the focus of the layout of real estate related enterprises in the process of innovation and transformation.

The measurement robot can help real estate enterprises realize the automatic measurement of real quantities at each stage of the construction process, and the explosion points are automatically matched to the wall of the corresponding drawings, so as to facilitate the rectification personnel to directly correspond to the rectification and retest verification through the mobile app.

Various project quality data reports 03 the automatic project quality management system places the measured real robot ucl360 at the planned next station and opens rongchuang Zhizao app for measurement.

Therefore, during the construction stage, the construction party and all participants shall conduct full inspection on the actual measurement link, the data can be traced and retained, and the measurement data can be reused by all participants, so as to comprehensively improve the operation efficiency of construction quality inspection.

Construction robots have become the focus of attention, and the research and application of intelligent construction equipment such as construction robots has become one of the key tasks.

The measured real robot ucl360 can automatically generate tables from the measured data and upload them to the client.

All data are directly viewed in rongchuang intelligent manufacturing app.

How many measurement methods does ucl360 robot have? Answer: there are two measurement methods: simulated manual ruler lowering and full wall measurement.

The measuring robot completes the automatic leveling, scanning, modeling of a single room in 3.5 minutes, fuzzy matching between drawings and models, result calculation, coordinate conversion, output of data and contour map, completion of blasting point on the wall, and automatic matching of blasting point data to the corresponding wall.

At present, the measurement of the whole wall is mainly used to measure the flatness of the wall.

Each wall is supported by tens of millions of point cloud data, and there is no dead corner quality monitoring.

The comprehensive efficiency is improved from the perspective of industrial chain..

“Robot building” and “intelligent building” are undoubtedly hot searches in the construction industry in 2021.

Xuhui group, known as a “Transparent Factory”, also shouted the slogan of “100% measured quantity”, requiring that the measured quantity should be transparent in data, process and supervision.

Data viewing method 2: the contour line of the whole wall measurement indicates the concave convex condition of the wall flatness through the color and positive and negative measurement values, and the flatness condition of the whole wall is clear at a glance.

The concave convex of the wall is clear at a glance, which is convenient for manual rectification; 3.

Three characteristics of full wall measurement: 1.

The measured real data is automatically uploaded to the mobile terminal CAD assistant in the whole process.

Taking the measurement robot as an example, let’s see how various enterprises implement it: real estate enterprises require 100% measured real quantity, and take “reaching perfection and reaching far” as the brand concept, Committed to building high-quality products, rongchuang group subversively put forward the concept of “100% measured quantity, interpreting quality with data”, and began to use the measuring robot ucl360 produced by Angrui technology in projects all over the country.

By re modeling the CAD drawing, the line segments and text information in the 2D drawing are transformed into BIM information recognized by the computer / algorithm.

Numerical measurement of the whole wall, breaking the upper limit of traditional manual ruler; 2.

Construction robots are gradually replacing people to complete construction operations under the conditions of large quantities, repeated operations, dangerous environment, heavy physical consumption and so on.

In recent years, real estate enterprises, general contractors and batch decoration companies have spared no effort in the investment of “intelligent construction”.

The mobile phone interacts with the drawing to intuitively find the next station position, one key automatic measurement, explosion point automatic on the wall, and contour map is convenient for rectification.

The CAD drawing is the result of the planning by the CAD assistant.

What are the three data viewing methods of wenucl360 robot? Answer: data viewing method 1: 3D model can directly view the data of each wall on the 3D model, which is very intuitive.

The combination of actual measurement of rongchuang Zhizao app and BIM application has separated people from data in the whole process of quality control, and paperless online data is real-time, fair, effective and transparent, creating necessary conditions for multiple use of data in all links in the process of intelligent construction, and greatly improving the comprehensive efficiency from the perspective of industrial chain, At the same time, it also greatly improves the construction quality.

The “list” has considerable guiding significance for the future development of intelligent construction.

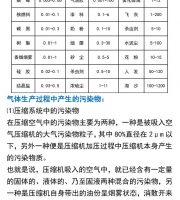

Rongchuang Zhizao app measured real quantity plate, so what is “100% measured real quantity”? How does the real robot work? Next, we will make a detailed description from the following aspects: 01 full wall measurement the measured real robot ucl360 developed by Angrui technology, whose measurement range is: Wall flatness and verticality; Squareness of internal and external corners; Height and width of door opening; Room space, depth, clear height, squareness and area; The ground flatness and levelness are extremely poor.

Easily find the explosion point: the whole wall measurement quantifies and reflects the construction quality with the detection of the overall wall data, provides the function of viewing the contour map, and helps the manual wall rectification with the positive and negative measured values, so that the rectification personnel can easily find the explosion point position of the corresponding wall.

The data during the construction of Party A’s project can be shared and used by the construction party, decoration party, property and other parties.

There is no need to record data manually in the whole process, which saves time and effort, and can avoid any human induced data error and fraud.

02 automatically upload data.

Data viewing method 3: data report to meet the needs of different end customers, our report can be customized according to customer needs.

Identify CAD drawing rules and information through artificial intelligence, carry out BIM information re modeling of drawings, provide effective information for automatic actual measurement, and provide structured data support for each stage of project management.

The measurement principle is: semantic segmentation, recognition and modeling of the wall, ground and ceiling of the house space, and calculation and processing of the ten million point cloud, so as to obtain the whole wall measurement data.