With the further promotion of aluminum mold, there is still room for the decline of rental fee and labor fee, and the cost will gradually occupy an advantage.

30 yuan / m2.

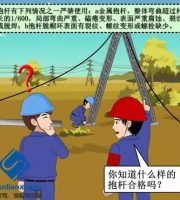

two Climbing frame construction 2.1 installation process of climbing frame: 2.2 advantages of climbing frame construction 2.2.1 the standard components of the scaffold are prefabricated in the factory and then assembled on the site, so that the scaffold is equipped, instrumented and standardized.

1.4.8 aluminum formwork has good rigidity, and a set of aluminum formwork can realize hundreds of turnover under normal construction conditions.

However, the unilateral cost of the internal and external wall plastering project is far lower than that of the wood formwork.

Wood mold is a necessary supplement to aluminum mold.

1 aluminum film construction 1.1 concept of aluminum film Aluminum alloy formwork is a building formwork made of aluminum alloy, also known as aluminum formwork.

It is an inevitable trend for aluminum formwork to be rapidly popularized in the domestic market.

Therefore, this paper analyzes the technical points of aluminum film, climbing frame and interspersed construction, so as to provide reference for construction enterprises.

It has complete supporting General accessories, which can be combined and assembled into a complex overall formwork with different sizes.

It is composed of three parts of aluminum panel, support and connector.

It has obvious advantages.

For real estate projects and projects with the requirements of observing and creating awards, the use of aluminum mold can achieve one-time survival, and the later rectification cost is much lower.

2.2.4 the bottom of the frame is completely sealed with the structural floor, which greatly eliminates the potential safety hazards.

2.2.5 the ground assembly, installation and removal at the construction site are relatively convenient, the operation is simple and rapid, the erection of frame body at high altitude is avoided, and the installation quality is easy to be guaranteed.

Compared with traditional wood formwork, the turnover times are also significantly increased, which actively responds to the requirements of relevant departments for green construction.

The material cost of wood formwork is 18-20 yuan / m2, which is basically the same as that of aluminum formwork.

Compared with other formwork, aluminum alloy building formwork has great advantages in construction period, cost, concrete quality, etc.

It not only has a positive significance for the project cost of high-rise buildings, but also has taken a big step on the road of industrialization of the construction industry.

At the same time, with the continuous implementation of industrialization in the construction industry, the construction configuration of climbing frame with aluminum film began to enter the public’s vision.

Both wood mold and aluminum mold have their own living space.

After using aluminum mold, it has little impact on the cost of wood mold such as garage.

Especially in the projects with demonstration sites and requirements for cup creation and award creation, its advantages are more obvious.

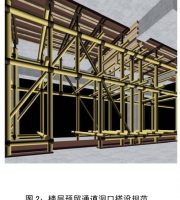

1 installation of wall and column formwork Fig.

2.2.2 compared with the floor type external scaffold, the one-time input of materials is greatly reduced.

If enterprises want to develop, they need to seek a breakthrough and deal with the challenge with the help of efficient construction methods.

However, the appearance quality of the two is quite different, and the wood formwork needs to spend the rectification cost in the later stage.

4 economic comparative analysis 4.1 comparison of economic benefits between aluminum film and wood formwork For a residential project in a city, except for the standard floor, the wood formwork construction and aluminum film construction are used for the second floor to the 29th floor above the ground respectively, as shown in Figure 1.

3 unit price analysis of aluminum film and wood formwork For conventional projects, when there are no special requirements for quality, the wooden formwork can be turned about 10 times at most.

Because aluminum molds can only be used in buildings with more than standard floors, wood molds are usually used in non-standard floors such as garage, first floor and top floor.

3 Installation at the intersection of beam and column Figure 4 Installation of internal corner formwork of wall formwork Figure 5 formwork support Figure 6 stairs 1.4 construction characteristics 1.4.1 the overall structure has high strength and good stability; High bearing capacity and good concrete apparent quality: 1.4.2 the flatness and perpendicularity of aluminum formwork are accurately controlled, and the concrete surface is smooth without pitting and slurry leakage, which can meet the construction quality standard of fair faced concrete.

There are many construction enterprises in China, and the construction level is uneven.

The development time of this mode is still short, and the technology is not mature.

The nine plywood is 50 yuan / piece, i.e.

If wood formwork is used, in order to ensure the appearance quality, 3-4 times of turnover are generally considered.

2.2.3 In the process of use, it depends on its own power to lift, does not occupy the tower crane, reduces the degree of labor, speeds up the construction progress, realizes the mechanized construction of high-rise building scaffold technology, improves the mechanization level of high-rise building construction, and promotes the progress of building construction technology.

1.2 construction process 1.3 picture collection of aluminum alloy formwork node installation Fig.

1.4.3 aluminum alloy formwork quick disassembly system has the advantages of light and fast operation, low labor intensity and high efficiency; 1.4.4 aluminum alloy formwork has beautiful and tidy appearance, high quality and good construction image; 1.4.5 supporting transportation tools for on-site disassembly and assembly, safe, efficient and easy operation; 1.4.6 all adopt finalized design, factory production and production, and the formwork engineering quality is excellent; 1.4.7 since there are few manufacturing and processing procedures on site, construction noise is reduced, energy conservation and environmental protection are achieved.

At this time, the cost is the most economical, about 37-39 yuan / m2, 8-12 yuan / m2 lower than the aluminum formwork cost of 45-51 yuan / m2.

Aluminum film has good appearance effect in practical application.

The third prize of 2020 excellent engineering cost academic paper of Chengdu Engineering Cost Association on cost analysis of aluminum film and climbing frame construction Zhong Sheng, Qu Xiaoxin, Wu Luojin (MCC Construction Engineering Group Co., Ltd., Chongqing) 404100) pick Important: in recent years, with the rapid development of China’s economy, new technologies, new processes, new materials and new equipment in the construction industry emerge one after another.

The secondary structure can realize thin plastering or even zero plastering.

It is not difficult to find that the economic significance of the aluminum film is concentrated in the secondary structure of the building..

The climbing frame not only has good overall protection effect, but also can be effectively interspersed with the subsequent construction of external wall plastering and guardrail installation, which lays a solid foundation for ensuring the construction period.

Compared with the traditional wood formwork construction method, the aluminum film does not have many advantages in the unilateral content of the main structure, and the early investment is also large.

Therefore, aluminum mold is an upgraded version of wood mold.

It can not only reduce the interference factors of construction personnel, but also improve the construction efficiency and help enterprises achieve the goal of reducing input and harvesting output.

Throughout the large construction enterprises, they are committed to the research of construction technology, which is the key to their long-term prosperity.

2 installation of beam formwork Fig.

For different projects, we need to analyze and select different template forms in order to achieve effect and profit maximization.

Compared with the limitations of aluminum formwork, wood formwork can be cut into any size required, especially in the application of special-shaped structure, which highlights the advantages of wood formwork.

It is designed according to the module and extruded by special equipment.

“Aluminum film + climbing frame + interspersed construction” mode is a construction technology rising in recent years.

With the continuous attention of construction engineering to quality, safety, economic benefits, civilized construction and social benefits, the advantages of aluminum formwork appear more and more.

Key words: aluminum film; Climbing frame; engineering cost 0 Introduction In recent years, China has vigorously advocated enterprise innovation and promoted the competitiveness of enterprises through R & D of various technologies.

For large-scale development of buildings, the use of aluminum formwork will greatly reduce the formwork cost.

The integrated attached lifting scaffold saves about 2 / 3 ~ 3 / 4 of steel on average, which is in line with the national industrial development direction of environmental protection, energy conservation and emission reduction.