Inspection method: observation and hand mold inspection 4.2.2 the plastering around corner guards, holes, grooves and boxes shall be neat and smooth, and the plastering surface behind the pipeline shall be flat.

2.4.3 installation conditions of water and electricity: check whether the water and electricity pipeline is installed in place before plastering.

4.1.2 the variety and performance of mortar shall meet the design requirements.

(3) The reserved groove position must be roughened.

Inspection method: check the product certificate, mobilization acceptance record, retest report and construction record.

If it exceeds 3mm, it shall be repaired with special putty first.

3.2.3 the thin plastering construction shall be started after the base course is cleaned.

Inspection requirements: organize special personnel to be responsible for plastering around holes, grooves, boxes and behind pipes.

III.

Stacking cement, river sand and mixing on site will produce a large amount of site dust and noise.

Inspection method: check the construction records.

(2) High horse stool shall be prepared before plastering, and the shelf shall be 20 ~ 25cm away from the wall for easy operation.

Plastering can be carried out only after the inspection is qualified and the pipeline and box edges have been repaired.

Compared with traditional plastering, it has the following advantages:_ Traditional plastering and thin plastering transport cement and river sand to the construction site in batches.

After plastering, the quality inspection department shall inspect and fill in the project acceptance records.

Inspection method: check the construction records..

Inspection methods: observation, measurement and inspection with tape measure.

The actual measurement of wall vertical leveling shall be carried out according to the measured data, and the plastering thickness shall be determined.

II.

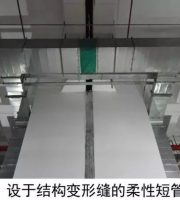

Your every message and every praise are the driving force for us to move forward! If the article is helpful to you, please forward it to your relatives and friends! Thin layer plastering refers to the plastering with a thickness of no more than 8mm, and the particle size of aggregate is preferably less than 1.25mm (control 50-80 mesh).

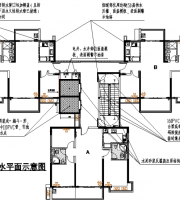

(2) Flatness: check with 2m aluminum alloy guiding rule, and the flatness error is required to be within 5mm.

The transportation cost is large, the stacking pollution on the construction site is large, the quantity is not easy to count, and it is easy to transport in place at one time.

The scraper shall be fully scraped vertically and then horizontally.

The dot screeding, hanging mesh, dot screeding, dot screeding and hanging mesh shall be completed.

When the same wall is constructed in two times, the upper part shall be constructed first and the lower part shall be constructed later.

The site is modulated by workers according to their memory, which is prone to uneven proportion, affecting the project quality.

(3) Squareness: set the squareness of the wall with internal and external corner ruler or infrared laser instrument, and the squareness error is required to be within 10mm.

(4) Paste grid cloth: alkali resistant glass fiber grid cloth (with a mass of not less than 120g glass fiber net per square meter), at the junction of aerated block and concrete, the overlapping width of each side of the grid cloth shall not be less than 100mm, and it shall be pasted with mastic.

It is easy to stack and modulate.

2.2.2 polymer thin-layer anti crack plastering mortar is adopted, which is refined from polymer, organic admixture, high-grade cement and additives.

The anti crack mortar shall be used up within 1 hour and plastered as soon as mixing.

Materials and products must have factory certificate, technical performance test report and operation manual, and the technical performance must comply with relevant national product quality standards.

(4) Determine the plastering thickness of the wall according to the checked verticality, flatness and squareness.

4.1.3 alkali resistant glass fiber grid cloth shall be pasted at the junction of aerated block wall and concrete, and the overlapping width of each side of the grid cloth shall not be less than 100mm.

The depth of base course and masonry mortar joint shall not exceed 3mm.

Construction preparation 2.1 technical preparation 2.1.1 be familiar with design drawings and requirements, select materials according to relevant standards and specifications, prepare construction scheme or technical measures, calculate material demand plan, and prepare technical safety disclosure.

construction process 3.1 process flow base course cleaning → check the verticality, flatness and squareness of the wall, and determine the plastering thickness → scrape the special mortar plastering layer → acceptance 3.2 key points of construction 3.2.1 Base course treatment (1) base course treatment of aerated block: remove surface sundries, residual mortar, dust, etc.

Inspection method: strictly follow the construction process requirements during construction.

Inspection method: observation.

2.4.2 during masonry construction, the construction shall be carried out in strict accordance with the specification requirements, the perpendicularity shall be controlled within 5mm, the flatness shall be controlled within 5mm, the squareness shall be controlled within 10mm, and the qualified rate shall be controlled above 95%.

Inspection requirements: the retest of materials shall be witnessed and sampled by the supervisor or the person in charge of relevant units, and signed for approval.

2.1.2 organize and arrange sample construction.

Inspection requirements: the base course must be inspected and accepted before plastering, and the concealed acceptance record shall be filled in.

There is no need to stack cement, river sand and no cement on site The manual transportation and batching and mixing of river sand can avoid dust and reduce noise on the site and effectively improve the safe and civilized construction on the site.

Mortar is mixed and paved with mortar, and the large surface is scraped Detailed end product effect Four quality standards for plastering 4.1 main control items 4.1.1 before plastering, the dust, dirt and oil stains on the base surface shall be removed.

3.2.2 determine the plastering thickness (1) perpendicularity: use infrared laser to check the perpendicularity of the built wall, and the perpendicularity error is required to be within 5mm.

The middle part shall be completed in the long direction of the same wall, and the internal and external corners shall be made finally.

Through comparison, it is found that using special mortar for thin plastering is conducive to energy conservation and emission reduction, comprehensive utilization of resources, promote the construction of an energy-saving society, ensure project quality, improve construction efficiency, reduce labor intensity and promote civilized construction, It helps to reduce the noise and dust pollution at the construction site, reduce the pressure on the urban environment, and promote the coordinated and sustainable development of economy and environment.

The thin plastering layer is very thin and the water loss is fast, so it is required to have high water retention rate (> 99%) and bonding strength.

The traditional method of environmental protection.

4.2 general items 4.2.1 the surface quality of general plastering works shall meet the following requirements: the surface of ordinary plastering shall be smooth and clean, and the joint shall be flat.

It can be modulated by adding water according to the proportion, which will not cause different hardness, and the quality is prone to hollowing, The cracking phenomenon requires two manual operations, which is laborious, time-consuming and costly.

The work efficiency of thin-layer plastering is very fast, and the wet operation of mud and water is eliminated, which provides necessary conditions for the insertion of subsequent processes.

Inspection requirements: operate in strict accordance with specifications and process standards.

4.2.3 the total thickness of plastering shall meet the design requirements.

The materials prepared through special mix proportion have superior adhesion and crack resistance, no hollowing and cracking, and their hardness is better than that of traditional plastering.

2.2 material preparation 2.2.1 calculate the quantity of materials required for plastering according to the construction drawings, and put forward the date of mobilization of materials in batches.

2.3 serial number of construction machines and tools tool name specification model quantity 1 infrared laser 1200w2 2 guiding ruler 2m13 internal and external angle ruler right angle ruler 25-50cm14 feeler gauge_ 15 steel tape 5m46 hand-held electric mixer_ 27 ash bucket_ eight 8 custom high Madden 1.5m49 stainless steel spatula_ four 10 handheld laser rangefinder class II laser, maximum output power ≤ 1mw12.4 operating conditions 2.4.1 before formal plastering, the template shall be first, and the full formal construction can be carried out only after the requirements are met and the construction interface is determined.

Generally, the plastering thickness is 3-5mm, and the maximum plastering thickness shall not exceed 8mm.