Building a people-centered building is to return the production process of construction products to the construction industry, return the user-oriented property, renewal and operation and maintenance to the housing service industry, and let the people realize the “housing dream” of safety, health and sustainability! Shanxi zhongzhijian group is a multi industry enterprise with CMA qualification certificate of national metrology qualification Third party testing organization.

Shanxi zhongzhijian group Click the blue word to pay attention to our technology efficiency.

The one-stop reliability testing technology service platform has professional technical team, scientific management system, positive service attitude, efficient communication mechanism, high-quality after-sales service, experienced testing scheme design, perfect process system from sampling to testing to output report, and provides all-round and one-stop testing services.

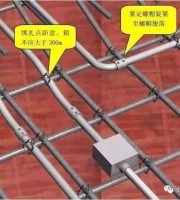

The air bag inflates and expands to fill the gap between the reinforcement tightly to ensure that the installation is vertical without inclination, and installed to the beam bottom without shaking.

Process operation flow guide 01 Airbag selection The diameter of the air bag shall be more than 20mm larger than the spacing of the horizontal bars of the beam, and the height of the air bag shall be more than 300mm higher than the design height of the plate beam section.

The technical application shares the construction technology of high-grade and low-grade concrete interception, the high-grade and low-grade concrete is used, the local mixed pouring and the cost exceeds the standard.

Compared with the traditional steel wire mesh stubble blocking process, the air bag stubble blocking process has the advantages of recyclable use, high strength, easy cleaning, high temperature heat sealing, tie resistance and wear resistance, good forming appearance, and low on-site operation difficulty, which can effectively speed up the construction progress, Better solve the problem of serial marking of high-grade and low-grade concrete, effectively avoid the appearance color difference of high-grade and low-grade concrete, and reduce the later repair.

Process introduction the construction process of high-grade and low-grade concrete interception refers to that after the reinforcement at the beam column joint is bound, the non inflated partition airbag is placed in the gap between the reinforcement, the small inflatable cylinder is used to inflate, the gap between the beam reinforcement is filled tightly with the inflatable expansion of the airbag, and then the high-strength concrete at the beam column joint is poured, After pouring, deflate and shrink the air bag and separate it from the concrete, pull it out and pour the beam and slab low-strength concrete, so as to effectively avoid high standard and low use of concrete.

The diameter and height of the air bag shall be universal as far as possible.

This issue mainly introduces “Construction technology of high and low grade concrete interception”.

However, this problem can be solved successfully by adopting “high and low grade concrete interception construction technology” in the core area of beam column joints.

As an important initiative of the construction company to reduce costs and increase efficiency, Guangdong Anshun construction also actively encourages employees to “innovate technology” and “share technology” in this regard.

Accounting for labor and equipment costs, a 25 storey building can save nearly 10000 yuan and achieve cost reduction and efficiency increase.

The traditional steel wire mesh stubble blocking process requires at least two small workers on the first floor, The construction can be completed within 1 day, which is affected by the binding progress of slab reinforcement; The first layer of air bag stubble blocking process only needs 0.5 small workers, which can be completed in 2 hours and is not affected by the process.

To further enhance the awareness of staff and the level of construction skills, the official account of “Anshun construction in Guangdong” will regularly organize all the technical skills in the construction, share them with each other, learn and progress together, and exchange new technologies and new skills with each other, help production control and control, and create high-quality projects.

These words often make the engineering people helpless.

Through practice, the air bag stubble blocking method adopted in the “high-grade concrete interception implementation process” has greatly reduced the difficulty of workers’ on-site operation and accelerated the construction progress.

Shanxi zhongzhijian group long press to pay attention to us!! Tel.: 0355-7888888 company address: Shop B6, yujingyuan, Changxing North Road, Changzhi City..

After simple cleaning, the air bag can also be used to the next floor or flow section to reduce cost and increase efficiency.

In terms of material control, “high-grade and low-grade concrete interception construction technology” greatly reduces the waste of materials, and each floor can save about 2 square meters of high-scale concrete.

Today, the technology product line is continuously extended and the quality is gradually improved, truly achieving specialization, branding and scale.

After the traditional stubble blocking method is formed, the new stubble blocking method works in two ways to reduce cost and increase efficiency.

02 positioning installation The installation position is set in the low-strength members, and the distance from the edge of the high-strength members is not less than 500mm.