Pay attention not to use bamboo and wood materials such as formwork leftovers, and pay attention to the selection of size according to the requirements of different structures.

3) The color shall be consistent with or close to the concrete, and the volume shall be as small as possible.

In the previous inspection, it is often found that the reinforcement is offset and sagging, resulting in the thin or even missing protective layer.

The use of cushion blocks should pay attention to: 1) cushion blocks of different sizes are used in different construction parts.

Type and selection of cushion block generally speaking, concrete, cement mortar, marble, granite, plastic cushion block and steel bar head brushed with anti rust paint can be used as cushion blocks, which are also more used materials.

At present, the problems of reinforcement corrosion and concrete cracking caused by improper setting of protective layer are common, which seriously reduces the service life of the structure.

Click the blue words above to pay attention to our concrete protective layer: the concrete used to protect the reinforcement from the outer edge of the reinforcement in the structural member to the surface of the member, which is referred to as the protective layer for short.

3.

4) When fine aggregate concrete is used, the cushion block is generally one grade higher than the concrete strength grade, and the specification can be 7cm × 7cm × Thickness of concrete cover.

2、 Selection and use of cushion block 1.

Under the joint action of overloaded vehicles and other reasons, some even need to be rebuilt.

4) Compared with the traditional cushion block, the plastic cushion block has the following advantages: it has the characteristics of standardization, finalization and universality, and the quality is stable; The thickness of the protective layer can be adjusted by adjusting different placement angles, which reduces the uneven thickness caused by human factors and is convenient to use; The cushion block has the advantages of light weight, small volume, high strength and corrosion resistance; The support is stable and not easy to fall off.

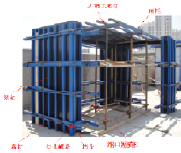

However, the commonly used square cushion block shape should be improved and the self-locking function should be added, as shown in the left figure.

In case of damage and displacement of reinforcement, they shall correct and repair in time to ensure the correct position of reinforcement in the concrete.

From the author’s practical experience, the following points are summarized for reference: 1) it should have sufficient strength, not easy to break and corrosion resistance.

In particular, the transportation vehicles are strictly prohibited to enter.

Therefore, concrete cover is an important structure in reinforced concrete members, but it is easy to ignore.

Its disadvantage is that the stiffness is not enough, which is easy to make the reinforcement mesh sag.

2) It is well combined with concrete and has close expansion and contraction performance.

Due to the limited service life, there is no relevant investigation record for reference.

The combination of cushion block and concrete is difficult to achieve the same effect as the overall pouring.

However, individuals have doubts about the bonding properties and anti-aging properties of plastic blocks and concrete.

The size deviation of formwork will also lead to insufficient or excessive protective layer.

1) Cement mortar is ideal in combination with concrete and color, but the cushion block shall generally not be lower than the strength grade of concrete.

2.

There shall be self-locking devices such as grooves to facilitate the fixing of reinforcement and prevent sliding.

In addition, the anti rust effect directly affects the service life of the members, which is difficult to supervise and is not recommended, especially on the flexural and tensile members.

2.

At present, this problem has attracted enough attention.

Simple connection with reinforcement, self-locking and no falling off.

For example, the service life of many bridges is about 15 ~ 20 years, far from reaching the design life.

Therefore, the construction unit shall carefully carry out the joint review of drawings and technical disclosure, so as to make the construction personnel understand that different construction parts have different requirements for the thickness of protective layer, rather than uniform.

During reinforcement processing, the setting out size shall be correct, especially for some drawings with dense and complex reinforcement layout, the setting out of reinforcement shall be carried out according to the actual situation after calculation, so as to avoid the inability to install due to the dense reinforcement at the junction point and the size deviation of the protective layer.

2) The construction personnel shall not walk on the beam and slab reinforcement at will and trample on the reinforcement mesh at will.

Cement mortar has defects in strength, and it is generally better not to use it.

Correct the bad habits during pouring.

If it is not well combined with the concrete, or the expansion and contraction performance is too different, it is easy to produce cracks or even fall off around the cushion block, so that the cushion block becomes a bad section with weak strength and a breakthrough point of water vapor erosion.

The concrete protective layer enables the reinforcement to have anchoring force on the reinforcement under the grip of the concrete, so that the reinforcement and concrete can bear the force together, and the steel-concrete structure can play a normal function and role; The concrete surface with too thick protective layer is prone to cracks.

The reinforcement workers must work on duty.

The dimensions meet the requirements.

2.

3) Fine aggregate concrete fine aggregate concrete is an ideal cushion block material and is recommended.

2) The number of cushion blocks shall meet the requirements, and the vertical and horizontal spacing of cushion blocks shall be controlled at about 100cm, which shall not be too large or too small.

At the same time, the protective layer can prevent the infiltration of humid gas and water, avoid the corrosion and expansion of reinforcement and damage the concrete, so as to maintain the durability of the structure and ensure its normal safe use function and service life.

Requirements of cushion block at present, there are no specific specifications and requirements for cushion block.

When the height of the structure is greater than 1.5m, the specification of concrete protective layer cushion block should be 10cm × 10cm × Thickness of concrete cover..

Personally, I think this is easy to be ignored.

The fabrication shall be standardized and the size shall be accurate.

These two problems are common in the construction process.

Therefore, attention shall be paid to the fabrication and installation of formwork.

After the removal of some formwork, the reinforcement can be found to be exposed, which must be corrected.

If there is a certain contrast between the color and concrete, the appearance is not very good.

At the same time, from the design and calculation model, it will also reduce the effective height of the section and reduce the flexural capacity of the section.

1、 The thickness of reinforced concrete protective layer depends on many factors, such as the environmental category of concrete structure, the strength grade of concrete, the specification of reinforcement and the type of concrete components.

2) The steel bar head brushed with antirust paint has the advantages of good combination, small volume and little impact on the strength of components.

3) When the reinforcement diameter is small, the cushion block shall be properly densified.

Therefore, the larger the cushion block size is, the weaker the bad section will be.

This will cause the displacement of steel reinforcement and the deviation of concrete cover thickness.

A movable operation platform shall be set up.

If the bonding performance is not good, cracks around the pad will easily cause corrosion of internal reinforcement.

1) during construction, especially in the parts with dense reinforcement, due to the difficulty of vibration, the operators sometimes pry the reinforcement with a vibrating rod or use the vibrating reinforcement to transmit the vibration force.

On the premise of adopting mass production and strengthening supervision to ensure construction quality, I personally think it is the best choice at present.