The failure of the material strength will directly affect the construction quality of the whole subgrade project.

The lower subgrade bed is mainly 0.8 to 1.5m below the subgrade surface, and the compactness of the subgrade bed shall be maintained above 96%.

Only when the quality of the foundation meets the specifications can the normal development of subgrade construction be ensured to the greatest extent.

If the depth from the road base to the pavement is less than 0.3m, the construction unit shall control the CBR value of the filler above 8.

The construction scale, work volume, the filling thickness of each layer of subgrade and the filling materials of subgrade are important factors affecting the equipment selection..

Conduct actual survey and Research on key technical indicators such as earthwork allocation and cutting section.

Research on highway subgrade construction technology and quality control Cheng Guo Zhan Huixiang Zhongyuan Road and bridge construction in Henan Province (Group) Co., Ltd., Nanyang 473000, Henan Abstract: in the process of highway construction, the construction quality of subgrade construction is a direct factor affecting the stability and reliability of highway.

For example, under the geological conditions of relatively flat operation surface, short length and shallow depth, the construction method of comprehensive excavation can be adopted.

In most cases, the construction unit will use the on-site CBR value to evaluate the strength of subgrade soil, and obtain a more scientific and perfect distribution of subgrade soil CBR value.

Compared with the upper roadbed, the strength requirements of the middle roadbed for the compacted filler can be slightly lower, and the CBR value of the filler can be lower than 8, but still higher than 5.

Only the materials meeting the strength can ensure the stability and reliability of the subgrade.

Then, according to the actual situation, formulate appropriate construction scheme and select appropriate construction technology.

0-0.3m below the subgrade surface is the upper subgrade bed of the subgrade.

When the slope ratio is less than 1:5, it can be solved by ordinary treatment.

2.3 subgrade compaction subgrade compaction construction needs to adopt appropriate construction technology and compaction equipment according to different subgrade levels.

2.2 the primary task of subgrade filling construction is to select appropriate materials.

In case of special circumstances, such as the use of composite foundation, the foundation needs to be reinforced according to the actual needs.

So as to ensure the service life of the foundation and reduce the impact and damage to the whole highway caused by subgrade permeability.

1.3 foundation flatness the flatness of the foundation seriously affects the stability of highway driving and the service life of the highway.

Subgrade construction can be carried out normally only when the following requirements are met.

Therefore, layered excavation can be used for assistance in this case.

Therefore, in the treatment of foundation slope, the appropriate construction scheme must be carefully selected according to the actual situation.

At present, most of the equipment used in domestic highway construction are large tonnage rollers.

As for the selection of filler types, the construction unit can select gravel mixture with good grading or cinder that meets the filler selection requirements after treatment and other fillers with high stability according to the actual situation.

After the subgrade excavation construction is officially started, targeted operations shall be carried out in the designated construction area in strict accordance with the construction technology formulated in the construction scheme.

The strength of the filler used for compaction of this layer must meet the specifications, and the CBR value shall not be less than 8.

In the area where the operation surface is relatively flat, but the operation length is relatively long and the depth is relatively deep, the method of longitudinal bench excavation can be used for construction.

Generally, the depth of operation in this case will exceed the maximum extent of direct mechanical excavation.

Key words: highway subgrade; construction technology; quality Quantity control 1 subgrade construction requires that the foundation is an important foundation for subgrade construction.

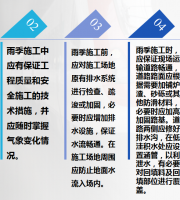

Rainwater is easy to enter the subgrade through infiltration, which has a great impact on the quality and stability of the whole subgrade.

If it is higher than this proportion, the connecting steps with a height of about 30cm and a width of more than 1m shall be excavated on the original foundation, and the steps shall be tilted inward, compacted and leveled to ensure that the strength and density of the steps meet the engineering requirements.

1.1 bearing capacity of foundation the bearing capacity of foundation is the main factor determining the stability and reliability of subgrade.

However, in the actual construction process, the construction unit must select the appropriate model of roller according to the different use conditions, because the use of roller has a specified range, and the precautions in the use process also have certain differences, which can not be incomplete.

During the construction of subgrade compaction, it is necessary to use mechanical equipment such as roller.

Therefore, we must strengthen the quality control of subgrade construction, control each process of construction process, select appropriate construction technology and ensure the construction quality.

The basic principle of material selection is not to select materials lower than the minimum strength requirements.

The construction technology and equipment used in the upper, middle and lower subgrade beds are different.

2 highway subgrade construction process 2.1 When the subgrade excavation is officially carried out, it is necessary to make sufficient construction preparations, investigate the natural environment around the construction, and analyze the main geological types of the construction area.

If necessary, interception, diversion and drainage measures shall also be taken, and permeable materials such as sand gravel with a certain thickness can also be laid.

According to relevant standards, If the filling height of subgrade is less than the thickness of subgrade bed (80) cm, the compactness of the base should not be lower than the compactness standard of the roadbed.

In most cases, there are three main requirements for Subgrade Construction on the foundation, namely, the bearing capacity of the foundation, the porosity of the foundation and the flatness of the foundation.

Ensure that the bearing capacity of the foundation can meet the current needs and lay a solid foundation for subgrade construction.

Therefore, in order to minimize the occurrence of foundation seepage accidents, the porosity of foundation filler must be strictly controlled.

1.2 porosity of the foundation affects the stability of the foundation If the foundation porosity does not meet the specifications, it is easy to have water seepage accidents.