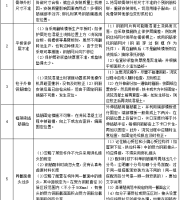

Concrete works 1.

1.

After concrete pouring, the comprehensive heat storage method shall be adopted for concrete curing, and a special person shall be responsible for temperature measurement.

Welding shall not be carried out on site in rainy and snowy weather.

The aggregate used for mixing concrete shall be clean and free from ice, snow, frozen blocks and other substances prone to frost cracking.

5.

Concealment and lag of quality accidents.

Source: in case of infringement by Tianjin construction safety supervision and management station, please contact to delete the characteristics of winter construction.

Before the installation of steel structure, in addition to the routine inspection, the component quality must be rechecked in detail according to the negative temperature conditions.

When the components of the same model are stacked, the levelness of the components must be ensured, and the cushion blocks must be on the same vertical line to prevent the components from sliding.

4) Temperature measurement method: the temperature measurement shall be carried out according to the number sequence of the temperature measurement hole.

6.

Arrange special personnel to measure the outdoor temperature, mortar and concrete temperature during construction and make records.

Anti skid measures must be taken when transporting and storing steel structures in winter.

The quality inspection and acceptance of reinforcement joints shall be carried out in batches.

Winter construction is a season of frequent engineering quality accidents due to unfavorable construction conditions and environment, especially concrete engineering and steel structure engineering.

Wind proof and shielding measures shall be taken for site binding, and the ice and snow on the reinforcement shall be removed in time.

Repair in light cases and re construction in heavy cases will not only bring losses to the project, but also affect the service life of the project.

The planning and preparation time of winter construction are strong.

Prepare the winter reinforcement welding operation instructions in advance, and organize the welding personnel to study to avoid blind construction.

2.

This is because the preparation time is short and the technical requirements are complex.

The preparation principle is: ensure the project quality; Economic and reasonable, so that the increased cost is the least; The required heat sources and materials have reliable sources and minimize energy consumption; It can really shorten the construction period.

6.

The water temperature shall be controlled at 70-80 ℃ (not higher than 80 ℃).

Portland cement and ordinary silica cement with high hydration heat shall be preferred, and the cement grade shall not be lower than c42.5.

4.

Hire consultants and experts to evaluate, screen winter construction methods and conduct special tests.

How to ensure the quality objectives of the project under the conditions of winter construction and rush to catch up with the construction period is the difficulty of construction technology and construction organization.

When welding must be carried out, effective shielding and protection measures shall be taken.

5) All temperature measuring holes shall be numbered and the layout of temperature measuring holes shall be drawn..

7.

The component stacking site must be flat and solid without puddles and ice on the ground.

4.

Special machines and tools for installing steel structures under negative temperature shall be inspected according to the requirements of negative temperature.

That is, the project is dry in winter, and most of them begin to be exposed in spring, which brings great difficulty to accident treatment.

There are often some quality accidents, which are caused by the lack of follow-up and hasty construction.

The minimum cement consumption shall not be less than 300kg / m3, and the water cement ratio shall not be greater than 0.6.

7.

The winter construction scheme shall include the following contents: construction procedures, construction methods, site layout, supply plan of equipment, materials, energy and tools, safety and fire prevention measures, temperature measurement system and quality inspection system.

There must be a winter construction safety production plan and implement it according to the plan.

Keep in touch with local meteorological stations and receive weather forecasts in time to prevent sudden attack of cold current.

7.

One beam measuring hole shall be set every 10m, with the hole depth of 1 / 3 of the beam height; One slab is set every 30m2, with hole depth of 1 / 2 of slab thickness.

3.

6.

3.

After the scheme is determined, relevant personnel shall be organized to study and make disclosure to the team.

Defects such as overheating, burns, biting and cracks shall be strictly prevented during welding.

Reinforcement works 1.

In the concrete mixed with antifreeze containing potassium and sodium ions, active aggregate or materials mixed with these substances in the aggregate shall not be used.

4.

Before stud welding, the welding current, welding time and other parameters shall be measured according to the negative temperature value to ensure the welding quality of stud under negative temperature.

Curing measures 1) early strength water reducer or antifreeze shall be added to the concrete during winter construction.

During the winter construction of formwork works, whether to add thermal insulation layer on the outside of formwork and the thickness of thermal insulation layer shall be determined by thermal calculation.

2) During winter construction, special personnel shall be assigned to measure the temperature to monitor the molding temperature and curing temperature of concrete until the concrete reaches the critical frost resistance strength.

When the outdoor air temperature is too low, necessary sealing and thermal insulation measures shall be taken for the reinforcement processing shed to ensure that the reinforcement will not be bent and straight thread formed at too low temperature.

In order to ensure the mixing temperature of concrete, the heating temperature of water must be strictly controlled.

The admixture added into the concrete should be chlorine free salt type, which can effectively improve the process performance of the concrete, improve the durability of the concrete, ensure the early strength in the low temperature period and the hardening under the negative temperature, and prevent early freezing.

4.

3.

2 before winter, special personnel shall be organized to prepare winter construction scheme.

Before pouring concrete, remove the ice, snow and dirt on the formwork and reinforcement, and preheat the formwork with a hot air blower: take windproof and antifreeze protection measures.

Once the concrete is frozen, conduct secondary heating and mixing to make the mixture have appropriate construction workability before pouring; Mechanical layered vibration shall be adopted during pouring, the layered height shall be strictly controlled, and the vibration speed shall be fast.

5.

If the component deformation caused by missed inspection during fabrication and transportation and stacking is greater than the regulations and affects the installation quality, it must be repaired and corrected on the ground, and can be lifted and installed only after meeting the design requirements and specifications.

The appearance of welded joints shall be inspected by welders first, and then accepted by quality inspectors.

5.

During mixing, aggregate shall be added first and then cement shall be added to ensure that the outgoing temperature is ≥ 15 ℃ and the molding temperature is ≥ 10 ℃.

2.

All gusset plates lifted at the same time with components, hanging ladders used by installers, fixtures and ropes for correction must be bound firmly.

When directly using lifting rings and lifting lugs to lift components, check whether the connecting welds of lifting rings and lifting lugs are damaged.

Uncooled joints after welding shall avoid touching ice and snow.

5.

3.

2.

If nonconforming products are found, they shall be reworked immediately.

Special measures for winter construction steel structure installation 1.

When the steel cable for binding and lifting steel members is in direct contact with the hook, an anti-skid spacer shall be added.

If there is snow, ice and condensation on the component, it shall be removed before installation, but the coating shall not be damaged.

The components installed on the same day shall form a spatial stability system to ensure the installation quality of steel structure and the safety of structure.

Detection of concrete quality during winter construction 1) measure the heating temperature of water and the temperature when adding mixing.

When the reinforcement connector is used for connection, it can only be used after negative temperature test.

Winter Preparation 1 during winter construction, the construction of the project shall be carried out continuously.

2) Measure the temperature when the concrete is discharged from the mixer and poured into the formwork, and measure it at least four times in each working shift.

Reinforcement used under negative temperature conditions shall be inspected and inspected during construction; The reinforcement shall be protected from impact and scoring during transportation and processing.

8.

4.

The steel structure shall be corrected immediately after installation at negative temperature, and shall be permanently fixed immediately after correction.

For negative temperature welding of reinforcement, flash butt welding, electric arc welding, pneumatic welding and other welding methods shall be adopted.

3) The measurement method of concrete curing temperature and the setting of temperature measuring holes (points) shall be set at the parts easy to dissipate heat when the heat storage method is adopted for curing; The measuring holes of cast-in-situ concrete beams and slabs shall be set perpendicular to the horizontal direction of beams and slabs.

During the installation of high-strength bolt joints, the friction surface of components must be clean, free of snow, ice, rain, contact with soil, oil and other dirt.

3.

The removal time of formwork and thermal insulation is determined by calculating the maturity value of concrete and the test block under the same conditions of pressure test concrete.

After the thermometer is inserted into the temperature measurement hole, block the hole and leave it in the hole for 3 ~ 5min, then quickly take it out of the hole to make the thermometer level with the line of sight, carefully read, record it in the temperature measurement record table, and cover the temperature measurement hole with thermal insulation material as it is.