IV.

(7) The construction disclosure shall be carried out in layers, and the construction technicians shall disclose to the team leader and quality supervisor, and the team leader shall disclose to the operation personnel.

Safety production, civilized construction, environmental protection and fire protection in Xi’an Relevant regulations III.

466 Lele Road, with one floor above the ground and frame structure.

Material and machinery plan 2.

(2) After the sampling and re inspection of facing bricks are qualified, the self-made sheathing plate shall be used to select bricks one by one.

emergency plan 7 X.

Cement: P.C # 32.5R cement shall be selected, and the retest inspection of raw materials must be carried out after the cement enters the site.

2.

Technical code for safety of high altitude operation in building construction (jgj80-91) 5.

Construction Schedule 1.

Assurance measures for pollution prevention and haze control 7 IX.

Preparation: review: Approval: July 2019 project record 1 project overview 2 2 preparation basis 2 3 construction progress 2 4 construction preparation 2 5 main construction methods and technical measures 3 6 quality assurance measures and construction standards 5 7 safe and civilized construction and assurance measures 6 VIII.

According to the drawing requirements, the exterior wall tiles of the project are 230 × 60mm specification, I easy to paste ceramic tile adhesive, which shall be constructed by our company.

2.

After the materials enter the site, the project department shall appoint a special person to receive and store them, timely take samples for retest, paste sample blocks, and conduct pull-out test.

The process flow of face brick inlaying of the North-South facade and West facade of the project: base cleaning → 15 thick 1:3 cement mortar priming and brooming, mixed with 3% waterproof powder → brushing a layer of plain cement slurry → 15 thick waterproof powder and waterproof sand Harvest rough finish of mortar cover → snap and arrange brick control line and detail line on the outer wall surface → paste model row and column bricks at internal and external corners and door and window openings according to the control line → inlay face bricks with 5-thick waterproof powder mortar → pointing with waterproof powder mortar → cleaning → curing.

The spacing of shooting nails shall ensure that the steel mesh does not warp and fall off..

(4) tdj2 theodolite shall be selected to check the geometric dimension and wall perpendicularity of the external wall of the main structure, and a through line shall be snapped at the large corner of the external wall.

The dimensional deviation of facing bricks shall be within the range specified in extruded ceramic bricks (GB / t4100-2015).

Among them, facing bricks, bonding materials and joint filling materials shall have the factory inspection report and product certificate of the manufacturer, and the geometric dimension, surface quality, water absorption, frost resistance and other indicators of facing bricks shall be rechecked.

3.

Material preparation face tiles, cement and easy to paste tile adhesive shall be products produced by professional manufacturers.

See the overall construction schedule for the construction schedule.

Construction sequence of exterior wall tiles: from top to bottom.

3.

Labor force plan: organize labor force scientifically and reasonably according to the schedule requirements of the construction period and the actual situation of the site.

main construction methods and technical measures 1.

Sand: medium and fine sand shall be selected, with good grading, and the mud content shall comply with relevant regulations and standards.

Each building shall organize independent external wall construction teams to carry out construction, so as to ensure the smooth realization of the construction period node.

It shall be fixed with shooting nails and gaskets.

Code for construction of Residential Decoration Engineering (gb50327-2017) 3.

Only after passing the inspection can it be used.

II.

emergency measures 7 appendix: 1.

The steel mesh shall be fully hung, and the overlapping width shall not be less than 5cm.

(6) according to the brick layout and color separation drawing, the non whole bricks shall be machined and cut by a special person at a fixed point, and uniformly stacked for standby.

Stability, strength and setting time must meet the qualified indexes.

Retest relevant materials before large-scale construction.

Project overview.

Preparation basis 1 Standard for quality acceptance of Building Decoration Engineering (gb50210-2018) 2.

The construction party shall complete the procurement and supply of face tiles.

East facade face brick inlay process flow: empty drum wall beating (the first leveling layer and the second base layer), the average thickness of knocking is 75 ~ 78mm → the wall is hydrated, cement and glue powder are sprayed → the wall is roughened → dotting → roughening, the roughening thickness is 75 ~ 78mm → cement mortar is troweled, finished, and the leveling thickness is 75 ~ 78mm.

This scheme is mainly for the construction of exterior wall facing brick.

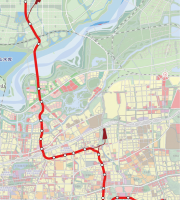

The reconstruction project 1# building of a certain Guoba factory is located at No.

V.

2.

At the same time, the surface of facing bricks shall be observed with naked eyes.

List of project personnel 1.

Technical points for the construction of external wall plastering and face brick inlaying: 1) the base layer is cleaned and the steel mesh construction base layer is cleaned with a tool shovel The sawdust, hanging slurry and floating ash of the formwork shall be removed.

(3) Before the decoration of the large surface of the external wall, special intermediate acceptance of the frame shall be organized, focusing on the unloading steel wire rope, wall connecting parts, frame deformation and frame protection.

Those with obvious defects and color difference are not allowed to be used.

Main equipment for construction machinery preparation includes: steel wire brush, chisel, hammer, leather hammer, brush, broom, bucket, iron trowel, wooden trowel, shovel, sieve, wooden bar, ruler, level ruler, vernier caliper, Self made (brick selection) sheathing board, plumb bob, box ruler, ink box, cement nail, shooting nail, lead wire, pencil, square ruler, finished plastic fixture, trolley, etc.

Specification of face brick: according to the drawing requirements, the color of face brick shall be jointly determined by the designer and the owner, and the site shall be selected and pasted according to the building elevation and the detailed drawing of external wall brick paving.

Code for construction and acceptance of exterior wall facing brick Engineering (jgj126-2015) 4.

construction preparation 1.

Preparation of operation conditions (1) Facing bricks, cement, sand, bonding materials and joint filling materials shall be mobilized and stored as required.

According to the construction schedule, the external wall plastering and tiling shall be started after the capping of the main structure.

(5) After the face bricks enter the site, a special person shall be arranged to take care of them to prevent them from soaking in water and being affected by moisture, which will affect the pasting construction.