Injection of water stop agent at the joint of steel pipe; 4.

The steel pipe with locking port forms a mouth-shaped pipe curtain.

Construction method of pipe curtain box culvert: propulsion scheme (rbj method); traction scheme (FJ method); push-pull combination scheme (ESA method) Project overview of the example of pipe curtain construction method: the pipe curtain and box culvert are located in ③ 1 gray muddy silty clay and ④ gray muddy clay layer, which are saturated soft soil.

Characteristics of pipe curtain construction method: no road reconstruction is required; Do not affect the normal traffic on the ground; No pipeline connection is required; No groundwater extraction; There is no need to strengthen house foundation and pile foundation; The pipe curtain steel pipe locking mouth can effectively prevent water leakage after grouting; Steel pipe laying requires high precision; Large project investment and high cost per linear meter.

Excavation in pipe curtain and support while excavation; 6.

The surface of the section where the tunnel passes through is quaternary Holocene manually filled soil, with loose structure and thickness of about 4m.

Let’s discuss the” pipe curtain method “in the auxiliary construction methods of the tunnel!” The purpose of auxiliary construction method in Tunnel Engineering: to form an advanced pre support system; Function: maintain the stability of tunnel face, control formation deformation and prevent collapse and roof fall accidents; Significance: it is directly related to the safety and economic benefits of the tunnel; Types: insert plate method, small conduit advance grouting method, shallow surface anchor bolt grouting reinforcement method, horizontal rotary jet or mixing method, freezing method, pipe shed method, pipe curtain method, etc.

Settlement control measures during pipe jacking in and out of tunnel technology: strict control Construction parameters of jacking; selection of appropriate building voids; strict control of deviation correction; ensuring the quality of slurry hydraulic grouting; ensuring the sealing of steel pipe lock and portal; necessary ground tracking grouting micro tunnel construction method: pilot micro tunnel construction method: spiral micro tunnel construction method: muddy micro tunnel construction method: steel pipe curtain jacking sequence: Based on the central axis of the cross section Treatment measures after quasi symmetrical jacking of pipe curtain from bottom to top: replacement of thixotropic mud (or backfilling and grouting outside the pipe) ; water stop treatment of steel pipe locking mouth; concrete filling of steel pipe; connection between steel pipe end and working well; settlement monitoring; buried monitoring points on roads above and around the pipe curtain, important buildings and adjacent tunnels; initial data collection shall be carried out before construction; for points that have passed or will pass through in pipe jacking construction and with large settlement changes, the monitoring frequency shall be appropriately increased; during grouting, it shall be followed Trace monitoring; when the monitoring value exceeds the alarm value, corresponding measures shall be taken immediately.

The thickness of the overburden at the top of the pipe curtain is 4.5m ~ 5.0m.

“In tunnel engineering, in addition to understanding common construction methods such as shield method, we also need to understand what auxiliary construction methods are used in the tunnel, because it is directly related to the safety and economic benefits of the tunnel.

Grouting or injection of concrete into steel pipe; 5.

The soil reinforcement range of the outlet section of the north and South working wells is L × B × H=8m × 38m × 18m; reinforcement strength: Qu = 0.8MPa.

Pipe curtain steel pipe laying methods: directional drilling; horizontal auger drilling; impact ramming; pipe jacking; micro pipe jacking / micro tunneling Drilling fluid for directional drilling method: overview of pipe jacking method working pipe or roadheader: manual pipe jacking; extrusion pipe jacking; air pressure balanced roadheader; slurry balanced roadheader; earth pressure balanced roadheader characteristics of slurry balanced pipe jacking: wide application range; small ground settlement caused by excavation; suitable for long-distance operation; good working environment, fast speed and high cost (spoil, site and equipment) ; large sludge water treatment capacity; it is easy to be blocked when the covering soil is very thin or the permeability coefficient is particularly large.

Construction difficulties of underground structure under pipe curtain protection: 1.

Source: the copyright of Zhulong forum belongs to the original author.

The characteristics of earth pressure balanced pipe jacking: wide range of applicable soil; small ground deformation; small covering soil thickness; convenient disposal of spoil; convenient and safe operation and good working environment; muck improvement is required in sand and gravel layer.

Construction of internal structure section by section and gradual demolition Support inside the pipe curtain, and finally form a complete underground passage.

They have large water content, low bearing capacity and small permeability coefficient.

Construction scheme of pipe curtain: box culvert advancing scheme: advancing the box culvert from two working wells in the north and south to the middle at the same time; before advancing the box culvert, the structural construction of the buried section above 100m shall be completed first, which shall be used as the back structure for advancing the box culvert; the soil reinforcement shall be carried out within 8m of the tunnel exit section to meet the stability of the excavation surface after the wall is broken; the soil in the pipe curtain is not reinforced, and the large grid A small grid is set inside to maintain the stability of the excavation surface under different working conditions; 80 2500kN jacks are set in each working well, which are promoted by hydraulic synchronous construction technology; by setting a reliable sealing water stop device, high-quality thixotropic mud is injected between the pipe curtain and the outer wall of the box culvert.

The locking port material is angle steel 100 × eighty × 10.

The minimum depth from the tunnel crown to the surface is only 2.5m, while the 110m long pipe curtain construction It is the first time in China.

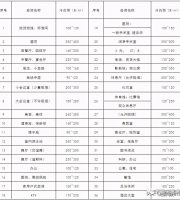

The size of the two working wells in the north and south is L × B × H=24.6m × 41m × 17m, the working well is constructed by underground continuous wall method, the wall thickness is b = 0.8m, and the soil penetration depth is h = 31m.

Scope of application of pipe curtain construction method: outline of pipe curtain design, design content: steel pipe configuration; Support arrangement in pipe curtain; Excavation sequence; Stability evaluation of excavation face; Analysis and control of surface subsidence; Control index of soil reinforcement design: allowable deformation of pipe curtain[ δ]= There are two parts of 5mm pipe curtain construction: 1.

Steel pipe curtain construction 2.

△ construction site drawing..

The construction of large section underground space with small diameter pipe jacking equipment; The principle is similar to the construction method of pipe shed, which belongs to high stiffness pipe shed; Originated in Japan, it is mainly used for Underpass engineering.

The tunnel is divided into left and right lines, of which the left line is 78m and the right line is 110m.

Control of surface deformation during pipe curtain construction: 1.

Steel pipe jacking, overlapping of steel pipes with lock mouth, and painting of water stop lubricant at the lock mouth of steel pipe; 3.

Box culvert: rectangular double hole reinforced concrete structure with two-way eight lanes.

Control of pipe curtain jacking accuracy 2.

The outer dimension of the structure: 34.2m × 7.85m, the box culvert is divided into 8 sections.

The length of pipe curtain section is 126m.

Construction of pipe jacking working well and receiving well; 2.

Here, take Xiamen as an example to introduce the construction process of the pipe curtain method: Xiamen city Gaoqi interchange connecting line intersects Xinglin bridge of the existing yingsha railway at a small angle, and the interchange connecting line passes through the tunnel.

Steel pipe curtain: 80 pieces Φ nine hundred and seventy × 10.