(11) According to the actual situation and structural form of the project, the division of inspection batches of each subdivisional project is confirmed: 1) steel structure welding subdivisional project: for the project, each frame can be used as an inspection batch; It can also be divided into several inspection lots according to different steel structure monomer or member types and the inspection lots of steel structure fabrication and installation.

key points for supervision control of steel structure engineering preparation (in advance) 01 qualification review of construction unit due to the strong professionalism of steel structure engineering, there are high requirements for professional equipment, processing site, worker quality and the enterprise’s own construction technical standards, quality assurance system, quality control and inspection system, Generally, most of them are subcontracted projects under the general contract.

(7) The bearing surface of steel members shall be close to the top of the embedded steel plate surface, the contact surface shall not be less than 70%, and the maximum gap at the edge shall not be greater than 0.8mm.

(3) The construction party shall conduct welding procedure qualification for the steel, welding materials, welding methods, welding heat treatment, etc.

Urge the construction unit to sort out the joint review minutes, and finally distribute them to all units after being signed and sealed by all parties.

(10) The component surface shall not be painted by mistake or missed, the coating shall not be peeled and rusted, and the coating shall be uniform without obvious wrinkles, sags, pinholes and bubbles.

The division of inspection lots can be divided into one or several inspection lots according to the division principle of inspection lots for steel structure fabrication or steel structure installation works.

(3) Inspect whether the production capacity of the construction enterprise meets the requirements of project progress.

(9) The coating, coating times and coating thickness shall meet the design requirements, and the allowable deviation is – 25mm, and the allowable deviation of each layer of dry paint film thickness is – 5mm.

2) Fastener connection subdivisional works: for works, inspection batches can be divided according to different steel structure units and fasteners of different specifications.

(2) If the reviewed construction organization design (scheme) needs to change the construction scheme (method) during construction, the reason and content of the change must be reported to the supervisor and the construction unit for review and approval.

Therefore, qualification review is an important link, and its review contents: (1) whether the business scope of construction qualification meets the engineering requirements.

3) Processing of steel parts and steel components: steel parts and steel components can be divided into several inspection batches according to different types.

Source: the copyright of Zhulong supervision belongs to the original author.

4) assembly of steel components: for large steel structures, steel components made in the factory shall be assembled into steel components as hoisting units before hoisting.

06 specific control points of steel structure engineering preparation (1) according to the unified standard for construction quality acceptance of building engineering gb50300-2013 and standard for construction quality acceptance of steel structure engineering gb50205-2020, as a divisional project, it is divided into steel structure welding, fastener connection, steel parts and steel parts processing, steel parts assembly, steel structure pre assembly Steel structure installation project, profiled metal plate, steel structure coating and other sub projects, as well as raw materials of steel structure (including steel, welding materials, coating materials, etc.), because they have a great impact on the quality of steel structure, they are separately included in the steel structure specification.

02 review of welder’s quality welders must pass the examination and obtain the qualification certificate, and the certified welders must perform welding in their examination qualified items and their approved scope.

The deformation of steel members and coating falling off caused by transportation, stacking and hoisting shall be corrected and modified.

(2) Inspection method: check the welder certificate, its recognition scope and validity period.

04 review of construction organization design (scheme) (1) urge the construction unit to prepare special construction organization design (scheme) according to the construction contract.

Due to the high requirements for component assembly, several components can be used as an inspection lot according to the actual situation on site.

For the installation of single-layer steel structure, the high-rise can be divided into several inspection batches according to the project zoning.

The treated steel surface shall be free of welding slag, welding scar, dust, oil stain, water and burr.

(5) When the embedded steel plate on the top of the reinforced concrete bracket on the engineering column is directly used as the bearing surface of the steel member, the allowable position deviation of the embedded steel plate on the bearing surface shall comply with the specifications.

(4) Before the installation of steel members, check the positioning axis (Bay size and span size) and elevation of the building, and the specification and fastening of embedded parts shall meet the design requirements.

7) Profiled metal plate works: profiled metal plate works include profiled metal plates used for roofs, wallboards, floors, etc.

03 drawing joint review and technical preparation according to the drawing joint review procedure in the supervision plan, get familiar with the drawings before the commencement of the project, convene and preside over the joint review of the drawings by the professional technicians of the designer, the owner, the supervisor and the construction unit, and solve the errors, omissions, irrationality and nonconformities in the construction drawings and the provisions of the national construction documents before construction according to the design documents and relevant data and specifications.

(8) The embroidery on the steel surface before coating shall meet the design requirements and the provisions of the current national standards.

Coordinate with the owner, design and construction units to determine specific treatment measures or design optimization for drawing problems.

Multi storey and high-rise steel structure installation works can be divided into one or several inspection batches according to floors or construction sections.

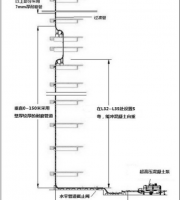

6) Steel structure installation: steel structure installation can be divided into single-layer steel structure installation sub item or multi-layer and high-rise steel structure installation sub item.

(6) Steel members shall meet the design requirements and the provisions of this specification.

8) Steel structure coating engineering: steel structure coating engineering includes anti-corrosion coating and fire-retardant coating.

I.

(2) Check the welder’s certificate, its approval scope and validity period.

5) Steel structure pre assembly: for steel structures with complex shapes, in order to ensure smooth assembly during high-altitude installation, pre assembly between relevant components shall be carried out on the ground after fabrication.

It shall be reported to the supervisor after being approved by the superior unit.

In this case, the qualification and management level of construction enterprises are very important.

(1) Inspection quantity: full inspection (on-site personnel).

used for the first time, and determine the welding procedure according to the qualification report.

(2) Whether the construction technical standards, quality assurance system, quality control and inspection system meet the technical index requirements of engineering design.

The supervisor shall fully inspect the welding procedure qualification report and inspect it according to the design requirements and weld quality grade standards.

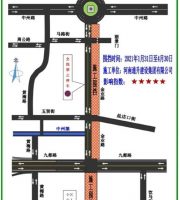

05 regular meeting organize and participate in the regular meeting of the construction site once a week, which is jointly attended by the construction, construction and supervision units, so as to solve the problems in construction in time.

It can be divided into one or several inspection batches according to deformation joint, floor, construction section or roof, wall, floor, etc.

The inspection batch can be divided according to the assembly between similar components as an inspection batch.

In terms of material, it includes profiled steel plate and profiled aluminum plate with anti-corrosion coating on the surface.

2) Urge the construction unit to witness the sampling and inspection of profile steel base metal, representative welding test pieces and bolts according to the provisions on witness sampling and inspection of housing construction engineering and municipal infrastructure engineering issued by the Ministry of construction and the requirements of specifications, and the test unit shall issue a qualified test report with witness sampling..

(12) The quality acceptance contents and corresponding qualification standards of divisional works shall comply with the following provisions: 1) steel structure welding, fastener connection, steel parts and steel parts processing, steel member assembly, steel member pre assembly, steel structure installation, profiled metal plate, steel structure coating and other divisional works shall comply with the qualified quality standards; 2) Quality control data and documents shall be complete; 3) The inspection and witness test results related to safety and function shall meet the requirements of corresponding qualified quality standards in gb50205-2020; 2、 Control points of supervision work in steel structure engineering 01 control points of supervision work of mobilization acceptance of raw materials and finished products (1) quality points of engineering materials: 1) check the appearance quality and quality certification materials of steel, welding materials, bolts, studs and other materials used in the project.