3、 Construction process flow 1.

The spacing of split screws in the middle of the beam is 400mm ~ 500mm.

The elevation of the upper opening of the side formwork of the beam shall be the same as the elevation of the plate bottom.

If the vertical pole joints cannot be staggered within 1.2m step distance, the vertical and horizontal steel pipes shall be used to strengthen the vertical pole joints.

The spacing in the direction of beam width (250 + beam width + 250) is adjusted according to the size of beam width, and 900 and 1200 are selected.

6m vertical pole and 4m vertical pole, 4m vertical pole and 3M, 2M and 3M vertical pole are staggered as the starting vertical pole of high formwork.

20cm cushion at the bottom of vertical pole × For 20cm square formwork block, the thickness of base plate shall not be less than 50mm, and the upright rod shall not fall directly on the concrete surface.

The plate bottom formwork shall first install the double steel pipe main keel on the U-shaped support, and install 50mm along the vertical direction of the main keel × 100mm wood brace secondary keel, and 15mm thick wood plywood is laid on the secondary keel.

2.

The side formwork of the beam shall be installed with the panel first, and the side formwork panel shall press the bottom formwork panel.

The installation of the bottom formwork of the primary and secondary beams is shown in the figure below: 1.4 install the side formwork of the primary and secondary beams and the bottom formwork of the slab.

The vertical pole under the plate is a wheel buckle steel pipe frame.

After the reinforcement of the primary and secondary beams is bound, install the side formwork of the beam and the bottom formwork of the slab.

Structural measures of frame body: continuous vertical cross bridging shall be erected around all full support frames, the lower frame body shall not be removed, the upper and lower support poles shall be set symmetrically, and vertical and horizontal cross bridging shall be erected every four spans within the support system, which shall not be greater than 5m.

When the vertical pole joints cannot be staggered within 1.2m step distance, the vertical and horizontal steel pipes are used to strengthen the vertical pole joints.

× nine hundred and fifteen × 16; The secondary ridge adopts wood brace, and the specification of wood brace is 50 × 100; The main ridge adopts double steel pipes with the specification of φ forty-eight point three × 3.5。 Formwork selection: 16mm thick red formwork, elastic modulus E = 4200n / mm2, bending strength [F] = 12n / mm2.

The beam bottom support frame adopts the fastener steel pipe frame, the water leveling rod shall be set in the middle of the frame body, and the U-shaped support shall be added at the upper end to adjust the thickness of the reserved beam slab bottom formwork.

Secondary keel: 50 × 100x2000mm wood brace, design value of shear strength is 1.3n/mm2, design value of flexural strength is 13N / mm2, and elastic modulus is 8415n / mm2.

The formwork support system must be provided with vertical and horizontal sweeping rods, and the height of the sweeping rod from the ground shall not be greater than 200mm.

Then, the secondary ridge of wood brace and the main ridge of steel pipe shall be installed, and split bolts shall be selected and fixed according to the formwork system design.

37 of the Ministry of construction) that special construction schemes must be prepared for dangerous and large projects.

The tightening torque of fasteners is 40 ~ 65N.

The installation of the side formwork of the primary and secondary beams and the bottom formwork of the slab are shown in the figure below: 2.

This formwork erection method is adopted for beam width > 500 (the spacing between vertical poles on both sides of the beam is 1200mm).

Diagonal braces on both sides of the support shall be set at the beam side according to the spacing of upright poles, which is the same as the spacing of upright poles of the full hall frame.

c.

The key points of operation are at the connection between the beam formwork and the column formwork, the influence of the expansion of the formwork after water absorption shall be considered, and the blanking size shall generally be slightly shortened, so that the formwork will not be embedded in the concrete after concrete pouring..

The spacing of vertical poles along the beam span direction matches the spacing of vertical poles of the full hall frame, with a spacing of 450mm.

3) When the frame starts, the vertical pole joints are staggered.

Generally speaking, the high formwork is the concrete formwork support project of divisional and subdivisional works with high risk.

The distance from the bottom split screw to the beam bottom shall not be greater than 150mm.

The main keel adopts Φ forty-eight point three × 3.5 ordinary steel pipe, bending strength 205.0n/mm2.

The beam formwork adopts 16 thick and multi laminate, and the size is 1830.

If the beam width is ≤ 500, this formwork erection method is adopted (the spacing between vertical poles on both sides of the beam is 900mm).

The vertical poles on both sides of the beam are added with full-length longitudinal horizontal leveling rods; Double steel pipe back ridge is set at the beam side, which is reinforced by M14 split screw, with a spacing of 500mm.

Two.

The steel pipe base shall be installed according to the needs of vertical pole combination.

M, and the anti sliding bearing capacity of single fastener can be 8.0 × 0.6=4.8kN。 The floor slab full support system in the high formwork area adopts the fastener type steel pipe frame (fastener type full support frame system), and the under beam support system adopts the fastener type steel pipe frame (the beam bottom support adopts jacking).

The full hall frame adopts wheel buckle steel pipe frame.

Material selection for formwork and support system.

Slab height formwork erection scheme 1) preliminary design: the floor formwork support system adopts fastener steel pipe frame, which is arranged according to the whole hall, and the spacing between floor vertical poles is 900 × 900mm, cross bar step 1200mm.

A horizontal diagonal bracing shall be added in the middle of the formwork height range of 8m and above.

The distance from the uppermost split screw of the beam to the plate bottom shall not be greater than 400mm.

Before erecting the support, 50mm thick base plate shall be laid at the lower foot of the frame body, and the upper and lower frames between floors shall be in a straight line as far as possible.

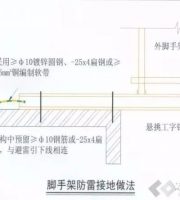

Schematic diagram of steel pipe base plate construction schematic diagram of steel pipe base construction after the erection of the full hall frame, the beam formwork support frame body shall be erected according to the designed beam support frame.

2) The plane layout of vertical pole is as follows: formwork support system beam plate elevation 3) A.

Large section beam erection scheme 1) plane and elevation design of frame body: the beam slab system is co erected, the high formwork support system is erected with fastener steel pipe support system, and the fastener steel pipe frame is added at the beam bottom to connect with the full hall frame with fasteners, with a size of 900 × 900mm, frame step 1200mm.

4) Setting of split screw on beam side: M14 split screw is set on beam side, and the number of passes of split screw is set according to the height of beam.

1.3 install the bottom formwork of the primary and secondary beams, install the horizontal leveling rod of the single steel pipe main keel along the beam span direction on the vertical rod on the beam side, install the double steel pipe main keel on the U-shaped support, fasten both sides of the main keel on the vertical rods on both sides of the beam with cross fasteners, and then lay the beam bottom 50mm according to the spacing × 100mm wood brace secondary keel, and 15mm thick wood plywood is laid on the secondary keel.

When the frame starts, the vertical pole joints are staggered.

A full-length longitudinal horizontal leveling rod shall be added to the vertical pole; b.

1.2 to erect the full hall frame, first erect the full hall frame poles on both sides of the beam, take the beam side poles as the starting point, and erect the full hall support frame on the beam side according to the spacing of the full hall frame poles.

2) Structural measures of frame body: continuous vertical diagonal bracing shall be erected around all full support frames, and vertical and horizontal diagonal bracing shall be erected every 4.5m inside the support system.

Installation process flow: snap beam axis and recheck → erect formwork → adjust joist → swing main beam → place beam bottom formwork and fix it → arch camber at beam bottom → tie beam reinforcement → install side formwork → stay wire support of side formwork (beam height plus split bolt) → recheck beam formwork size, elevation and position → connect and fix with adjacent formwork.

the plane size of plate underframe body is designed to be 900 × 900mm, frame step 1200mm.

erection scheme 1.

The erection scheme of small section beam adopts the erection method of adding a vertical pole at the bottom of the beam.

Two to four rows of split screws are arranged on both sides.

d.

Erection process of high formwork support 1.1 measurement and setting out snap the side line of the beam on the bottom plate or floor plate structural plate surface, so as to determine the position of vertical poles on both sides of the beam and the layout of vertical poles under the beam.

High formwork material parameters U-shaped jacking diameter 14mm split screw III.

Elevation 3.

A U-shaped jacking is arranged on the vertical pole, and a double steel pipe main ridge is arranged on the U-shaped jacking.

The beam formwork erection method is along the beam span direction.

The horizontal cross bridging is set at the bottom of the frame, the first step horizontal bar under the beam, one in the middle of the floor with a floor height greater than 8m, and a horizontal safety net is fully paved at the middle horizontal bar of the frame.

The horizontal cross bridging is set at the bottom of the frame, the first step horizontal bar under the beam, one in the middle of the higher floor, and a horizontal safety net is fully paved at the middle horizontal bar of the frame.

Derived from the definition of civil engineering network I and high formwork, the Ministry of housing and urban rural development stipulated in the provisions on safety management of dangerous divisional and subdivisional works (Order No.