Strictly implement national, local and industrial construction specifications, acceptance evaluation standards and technical quality standards specified in the contract during construction; Carry out work according to the requirements of the company’s quality system documents and the established quality management system and project quality plan.

Quality accidents shall be reported truthfully, carefully investigated, analyzed and handled.

Be responsible for the management of quality assurance data.

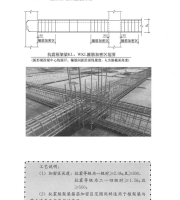

Carry out daily patrol inspection on the construction works, and carry out on-site supervision on key processes and special processes of concealed works..

(4) the technology and quality department is responsible for the division of unit works; Be responsible for organizing the application for inspection of equipment, measuring instruments and special type of work certificates used by the participating units; Organize material inspection and construction process inspection before reporting for supervision; Organize self inspection and professional handover inspection of all participating units; Organize the inspection and evaluation of unit works and submit the project acceptance report to the owner; Be responsible for organizing the investigation, analysis and handling of quality accidents.

Organize the inspection and evaluation of divisional works, and invite the supervisor to organize inspection and acceptance after the review meets the requirements.

Be responsible for the quality management and process control of the project undertaken by the unit, and divide the divisional works, subdivisional works and inspection lots; Assign special quality inspectors to be responsible for self inspection of inspection lot and concealed works; Be responsible for ensuring the collection and management of data; Be responsible for the evaluation of divisional works and participate in the evaluation of unit works.

(3) quality management leading group the quality management leading group is responsible for organizing the overall control of the factors affecting the construction quality, and strictly implementing the national and local quality regulations and the quality management policy of the group company.

Establish and improve the quality management system in the whole construction process according to the requirements of the company’s quality system documents, and be fully responsible for the establishment and operation of the project quality system and project quality management; The work shall be carried out in strict accordance with relevant national inspection and evaluation standards and technical quality standards specified in the contract, as well as the provisions of the owner, the supervisor and the quality supervision department, the contract requirements and the project quality plan.

Solar power stations, solar water heaters, electric vehicles and energy storage power stations are all based on the mass production of batteries, and solar cell production is the demand side of purification projects.

Thank # warm Meng for pursuing excellence and Zhai Lijuan for sharing the materials.

Be responsible for rechecking and signing the inspection lot before quality acceptance; Be responsible for process handover inspection and visa between concealed works and disciplines; Be responsible for contacting the supervision and quality supervision departments for various quality inspection and acceptance, and patrol inspection, side station and supervision of the whole construction process; Organize regular quality meetings regularly; Participate in the investigation, analysis and handling of quality accidents; The quality control points shall be defined and the process control procedures for the quality control points shall be formulated.

Be responsible for project quality, safety, construction period, cost and civilized construction.

Quality accidents shall be reported timely and truthfully.

6.1.2 quality management responsibilities (1) project manager the project manager is the first person responsible for the project quality and is fully responsible for the project quality; Implement the company’s quality policy on the project; Fully perform the project contract; Be responsible for organizing the formulation and implementation of project quality plan.

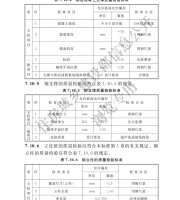

(2) the chief engineer of the project management department shall organize the technical quality department and the operation and finance department to divide the unit works according to the standards, specifications, design documents and contract requirements; Formulate inspection and test work plan; Report the project division list, inspection and test plan, construction equipment, special type of work certificate and other data to the supervision and quality supervision station in time.

Ensure the effective operation of the quality assurance system in the project.

(5) each professional quality inspector shall organize self inspection and evaluation of the completed inspection lot and subdivisional works, which shall be rechecked by the professional inspector of the unit.

The procedure documents require the control of nonconforming products.

Therefore, starting today, I will share the construction organization design of solar cell production projects with you.

Participate in the company’s regular joint inspection and quality meeting; Participate in the acceptance of subdivisional and divisional works organized by the supervisor and unit works organized by the owner; Supervise and inspect the quality behavior and project quality.

After meeting the requirements, it shall be reported to the technology and quality department for recheck, and the supervising engineer shall be invited to organize acceptance.

Control the nonconforming products according to the requirements of the procedure documents of the group company.

Discuss and make decisions on major quality activities.