After checking that there is no abnormality, start the diesel engine and run it at low speed for 5-10} minutes.

(7) Start, operation and shutdown of air compressor: 1 Before startup, check whether the cooling water, diesel and compressor oil of the diesel engine are filled as required.

Turn the fan of the main engine by hand for 2-3 turns to see if it can move freely, and check whether there is a sense of obstruction or abnormal sound.

During operation, always check whether the reading of the pressure gauge is normal and pay attention to the operation stability of the machine; Whether the vibration and sound are normal; Check whether all parts are in normal state; Whether the heating condition of the moving parts is good.

The suction valve automatically opens under the action of atmospheric pressure, and the air is sucked into the cylinder through the filter muffler.

The drilled holes are usually called blast holes or blast holes.

Fill with lubricating oil.

Pressure control: when the air pressure in the air storage tank exceeds 1.05 times of the specified exhaust pressure, the venting system will automatically open to discharge excess compressed air.

In the construction of power transmission line, the air compressor is used as an energy source to drive the rock drill (air pick) to drill blast holes or drill holes of rock foundation in the excavation of foundation pit in rock zone.

When working in the environment below 0 ℃, the lubricating oil shall be heated to above 0 ℃ to start the machine, so as to prevent the engine body damage caused by the solidification of lubricating oil.

(III) structural features of air compressor: the air compressor is mainly composed of main engine, diesel engine, transmission system, pressure control system, air storage tank, etc.

(II) working principle of air compressor: the engine drives the air compressor crankshaft to rotate through belt transmission.

When ascending, the cylinder volume decreases gradually, the pressure and temperature rise, and the suction valve closes automatically under the action of pressure difference.

It has the characteristics of good integrity, concise structure, easy handling, convenient use and maintenance, etc.

Thus, the suction compression exhaust working cycle is realized, and the compressed air with atmospheric pressure is transformed into compressed air with certain energy for various pneumatic tools (such as air drill, etc.).

It can be organically combined with rock drill, water injector, hollow drill bit and hexagonal drill pipe.

Fully open when there is external load.

When the crankshaft rotates, the connecting rod drives the piston to move up and down in the cylinder.

and organically combined.

1.1 air compressor [overview] air compressor is a compound machine among construction machinery, that is, it is a construction machinery that converts power energy into compressed air energy and then provides working power.

It is designed with an automatic clutch.

Safety valve: when the air pressure in the air storage tank exceeds 1.1 times of the specified exhaust pressure, the safety valve will automatically open to make the pressure drop rapidly to ensure the safety of the system.

Its power source includes motor and internal combustion engine (diesel engine).

Regulation and safety mechanism of air compressor: pressure gauge: directly display the air pressure in the air storage tank.

At present, S195 and S1100 diesel engines are commonly used in power transmission line construction.

The purpose of drilling holes is to fill explosives in the holes and blast down the rock or concrete.

2.

4.

Open the gas transmission valve to start the air compressor at no load.

Start the machine and make the machine run without load for 5-10} minutes before it can enter normal operation.

If there is no abnormality, close the gas transmission valve and adjust the pressure to the rated value for 2-3 times.

5.

The crankshaft rotation direction is counterclockwise as viewed from the pulley end.

When the pressure exceeds the pressure in the air storage tank, the exhaust valve will open automatically and the compressed air will be sent to the air storage tank through the exhaust pipeline.

For machines that operate continuously for a long time, in addition to paying attention to diesel engine oil, cooling water, diesel and compressor oil at any time, oil-water dirt shall be discharged under pressure at least once or twice a month.

3.

01 introduction to rock drilling machinery [purpose] it is used to drill holes on rock and concrete surfaces or break rock and concrete surfaces.

There shall be no heat source within 15m from the air storage tank..

Gate valve: used for loading when checking and adjusting machine performance.

The machine must be managed and used by a specially assigned person.

Generally, the temperature of the exhaust port of the cylinder shall not be higher than 200 ℃, and the oil temperature of the crankcase shall not exceed 70 ℃.

(VIII) safety technical regulations for use of air compressor: 1 The workplace of air compressor shall be kept clean and dry.

When the speed of the diesel engine is lower than 700 ~ 800 rpm, the power and compressor will be separated automatically.

The air compressor uses a single cylinder diesel engine as the power source, and the transmission adopts ordinary B-type triangular belt.

4.

7.

When the piston goes down, the cylinder volume gradually increases and the pressure decreases.

(I) composition of air compressor: the air compressor is mainly composed of main engine, diesel engine, transmission system, pressure control system, air storage tank, etc., which are effectively combined together.

6.

Check or add diesel engine oil, diesel oil, cooling water and compressor oil as required before and during each start-up, especially the oil level of air compressor oil must be at the specified position (1 / 3-2 / 3 of oil window), otherwise the low oil level will easily cause Bush burning, shaft holding and cylinder pulling; If the oil level is too high, the fuel consumption will be too high and the air valve will be damaged due to carbon deposition.

[composition of rock drilling machinery] rock drilling machinery is mainly composed of engine, air compressor, rock drill, hollow drill bit, hexagonal drill pipe, water injector, etc.

At the end of each work, the air compressor can be shut down after running for 3-5 minutes without load.

At present, the air compressor with nominal volume of 1.8m3/min is commonly used in construction.

In case of rainy season or areas with high air humidity, it shall be discharged under pressure 3-5 times a month to ensure that the interior of the machine is clean and the air compressor is pure.

(VI) inspection before startup: 1 Clean and check whether all fastening parts are loose and in normal condition.

The pressure limiting valve must relieve pressure within the specified pressure range.

2.

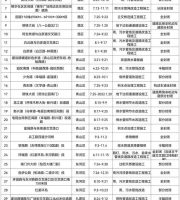

(4) Main technical parameters of air compressor: table 1-1-1 main technical parameters of air compressor (V).

8.

3.