50mm thick wood plates are laid on each layer, and 3mm steel plates are laid on the top layer.

The five practical data treasure houses of members of 2021 “engineering practice reference” will help you quickly become an engineering quality and safety expert! Member hot reservation…

In 2021, member 02 of engineering practice reference attached this elevator.

The height of the first to second floors is 4.8m, the height of the overhead floors is 4.5m, the rest is 2.8m, and the total height of the building is 100.23m.

(9) the installation of vertical pole and attachment frame must be set layer by layer according to the actual requirements.

Debug the electrical equipment.

There shall be no other obstacles within the installation range, and safety warning signs shall be set.

(10) after the standard guide rail is installed to the required height of the building and the crown wheel is installed, the limit shall be kept at least 3M from the crown wheel..

(3) install the lower limit position, and the lower limit travel switch touches the iron.

Four M20 attachment bolts are set on each attachment support plane, and 100 bolts are set at both ends of the structure × one hundred × 10 thick steel base plate, and the allowance of bolt end shall not be less than 20mm.

5、 Installation and removal of construction elevator 01 preparation before installation ⑴ after the construction elevator enters the site, the safety equipment department of the branch company must provide the certificate and operation manual, and check the preparation one by one according to the technical requirements in the safety technical acceptance sheet for construction elevator installation.

Temporary column 300mm × 300mm,8 Ф 18.

Since the elevator is located on the basement roof and the first floor loading platform is relatively high, the elevator chassis is directly installed on the floor after strengthening the 200 thick basement roof, which can reduce the height of the first floor loading platform.

The material platform is fully paved with 50mm thick wood plate, with an area of 5200 × 1400mm2。 Protective railings shall be set on both sides of the material platform and enclosed with dense mesh net, with a height of no less than 1.2m.

See the elevator foundation plan at ± o.ooo for details.

After iron collision, the standard guide rail can be installed in the next step.

Adjust the clearance between the guide roller and the rack to an appropriate position, and conduct the up and down test within 1m from the ground, subject to the limit that the elevator cannot slide automatically.

(8) installation of standard guide rail: generally, 4-5 sections are appropriate.

02 installation sequence (1) transport the construction elevator chassis to the foundation, after leveling, fix it on the foundation according to the drawing requirements, and fill the bottom gap with 1:3 cement sand.

The power supply equipment meets the requirements.

(2) install three standard sections, which can be assembled on the flat ground, lifted and installed by tower crane.

While installing the attachment, the perpendicularity of the guide rail must be corrected to keep the perpendicularity within 9cm.

See the elevator foundation plan at ± 0.000 for details.

Click me: the members of 2022 are hot to book the latest practical series of high-quality materials for the project (November 2021 version).

(7) install the cable and set the cable cage.

03 through wall bolts are used to connect the attachment and building structure.

Member hot reservation…

Steel wire rope unloading measures shall be set every ten layers of the material platform.

For the loading platform between the people and goods elevator on floor 04 and the loading platform between floors 1-16, 4 pairs of double vertical poles are used to erect from bottom to top, 4 pairs of single vertical pole tubes are used to erect above floor 17, 4 pairs of single vertical pole tubes are used to erect from bottom to top, and the connection with the floor adopts frame tubes.

The safety officer is responsible for comprehensive safety management.

It is adjacent to Luban Road in the East, Liyuan Road in the south, Xiexi road in the West and taiqifeng in the north.

05 waiting shed is 6m outside the entrance of passenger and cargo elevator × 6m protective shed with a height of 6m and a buffer height of 700mm.

3、 Selection of installation location since the project is divided into one main building in the South and one main building in the north from more than three floors, there is only a hall on the first floor of the middle structure on the south side of the South Main Building and the north side of the north main building, and there are no obstacles above the second floor, so the elevator floors here adopt the post pouring method and reserve steel bars.

During installation, the concrete reaches 100% strength and the surface is flat.

(4) staffing: 1 Mechanical Engineer responsible for installation, 1 mechanic and mechanic, 1 elevator driver, 1 electrician, 1 welder and 3 scaffolders.

(3) working environment: the elevator foundation has been poured according to the construction elevator layout and reinforced concrete requirements.

The upper limit position and upper limit travel switch must be installed at the upper end.

It is required to install one on each floor from the first to the third floor and one on every two floors above the third floor.

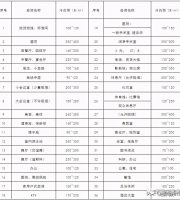

2、 Selection of vertical transportation construction elevator according to the actual situation of the project, scd160 / 160 construction elevator produced by Shandong Laizhou construction machinery factory is selected, and its mechanical performance and technical index rated load is 2 × 2000kg or personnel 2 × 15 people, free working height of 7.6m, maximum lifting height of 110m.

4、 Method statement 01 geometric dimension of foundation base plate is 5400 × three thousand and four hundred × 200.

After assembly and fastening on the flat ground, lift it in place and fasten it with a tower crane.

The method of adding temporary concrete columns and beams under the derrick bottom and loading platform frame is adopted to directly transfer the upper load to the foundation slab.

Operating speed 15-35 M / min, power 4 × 11 kw, which can fully meet the actual needs of the project.

Drainage measures shall be set for the foundation, and 500 shall be set at the side of the foundation × five hundred × 500 sump, pump water in case of precipitation.

(4) put the lifting cage in place, release the DC brake of the driving motor when it is in place, and recover after it is in place.

The project has one underground floor and 30 main buildings on the ground.

1、 Project overview Shanghai Datong Garden Phase III project is located in the center of Luwan District, Shanghai.

Stirrup Φ 8@100 For temporary beams, refer to the construction of adjacent beams, and add 100% plate reinforcement according to the original reinforcement.

This should be paid special attention to and safety must be ensured.

(5) place the counterweight of the cage in place and pad square timber with appropriate height under it.

(2) the installation personnel shall work with certificates and be familiar with the safety operation procedures of construction elevator according to the safety (technical) disclosure.

(6) adjust the hand brake pull rod to meet the requirements of smart opening and tight stop braking.