indicated on the transportation list are consistent; 3.

Therefore, appropriate thermal insulation measures must be taken at the initial stage of concrete setting and hardening.

In order to ensure that the concrete quality meets the requirements of national standards, the following effective measures will be taken for the concrete produced by our factory in winter: 1.

In order to prevent quality accidents to the greatest extent, we now introduce relevant matters below, in order to get good results and help you create an excellent project.

When the outdoor daily average temperature is lower than 5 ℃ for 5 consecutive days, the concrete will be mixed with antifreeze or early strength agent (if required by the demander, it shall be notified in writing).

6.

3.

While our company takes technical measures for concrete construction in winter, the pouring, curing and maintenance of concrete will also have a direct impact on the quality of concrete structure.

The freezing of concrete is mainly due to the freezing of water.

China’s industry standard code for winter construction of construction engineering jgj104-2011 stipulates that when the outdoor daily average temperature is lower than 5 ℃ for 5 consecutive days, winter construction will enter.

The change of winter climate will make the concrete products accept a more severe test.

The joints between the formwork shall be tight without mortar leakage.

After the concrete arrives at the construction site, the construction unit shall have professional quality inspection personnel sign for acceptance; 2.

When the temperature is lower than 0 ℃, most of the water in the concrete freezes.

5.

When the column height exceeds 3M, the tumbling barrel or inclined chute shall be installed on the side of the component for sectional pouring.

Concrete pouring (1) reasonably use the paving method.

(2) During concrete pouring, the paving thickness shall be strictly controlled.

If any problem is found, stop unloading and immediately notify our company for timely treatment.

First, check whether the client and project parts, strength grade, slump, etc.

Ensure the concrete pouring temperature to ensure that the concrete pouring temperature is not less than 5 ℃ (mass concrete is not less than 3 ℃): ① during pouring, our on-site service personnel will reasonably arrange vehicles to ensure that the concrete is transported to the site for pouring quickly after leaving the machine, and shorten the transportation and parking time as far as possible.

When the column height is less than 3m, the material can be directly discharged from the top.

If the concrete surface is vibrated excessively, bleeding or bleeding will occur on the concrete surface.

In line with the attitude of being responsible for the project quality, our company puts forward higher requirements for the concrete production at this stage, and has formulated a set of perfect winter construction technical scheme: in the process of winter concrete construction, our company adopts the methods of antifreezing and water reducing agent and reducing the water binder ratio to strengthen the raw materials, production process and quality control, To ensure the delivery, transportation and pouring of concrete and minimize the quality risk.

Add antifreeze.

Therefore, reducing the water consumption of concrete and properly reducing the slump of concrete can reduce the water content on the concrete pouring surface and prevent freezing.

During concrete pouring, it is not allowed to mix with concrete outside our company at the same part, and it is not allowed to add any materials to the concrete produced by our company without permission.

The pouring shall be completed within 1 hour after the concrete leaves the factory.

Cement selection and dosage: Portland cement and ordinary portland cement are preferred; The cement consumption of concrete shall be ≥ 300kg / m3, and the water binder ratio shall not be greater than 0.6.

2.

4.

5.

3.

When the temperature is 0 ℃ ~ 5 ℃, the water activity is low, the hydration reaction of cement is extremely slow, and the strength development of concrete can not meet the requirements.

The demander is requested to take the following measures for concrete insulation, antifreeze and crack prevention: -.

Aggregates containing ice, snow and frozen blocks shall not be used.

In order to avoid cold joints, the second layer of concrete must be poured before the initial setting of the lower layer of concrete.

2.

2、 Concrete construction 1.

Dear} construction and supervision unit: with the decrease of temperature, it is now in the winter construction stage.

Inspect whether the color of concrete is abnormal and whether the workability meets the construction requirements; 4.

4.

If the pouring time is too long and the slump cannot meet the construction requirements, it is forbidden to add water into the concrete, which can be properly adjusted with the admixture carried with the vehicle.

Formwork removal (1) when removing the formwork, it is not allowed to form impact load on the floor.

Concrete mobilization acceptance 1.

Extension of mixing time in order to ensure the uniformity of concrete mixture, the concrete mixed with antifreeze shall be discharged after the mixing time is extended by 10s compared with that at room temperature.

The removed formwork and supports shall be stacked separately and cleared away in time.

After pouring, it shall be rubbed with a wooden trowel for more than two times.

(3) Concrete vibration shall be dense and avoid over vibration and missing vibration.

After adding admixtures into the concrete, mix evenly, and the concrete mixer shall mix at high speed for more than 5 minutes.

After the concrete arrives at the construction site, it shall be poured in time to avoid the loss of slump and temperature.

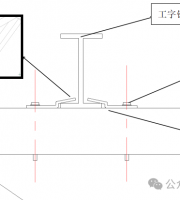

The supported formwork can effectively bear various construction loads and ensure no deformation, damage and collapse during construction.

② When the outdoor average temperature is lower than 0 ℃, steam will be used to heat the water to make the water temperature > 50 ℃ to ensure the concrete formwork temperature.

During plastering, the water on the concrete surface must be scraped off, and the laitance on the surface shall be pressed into the concrete.

6.

Corresponding technical measures should also be taken for the preparation and construction of concrete.

After water turns into ice, the volume expands and destroys the internal structure of concrete; In addition, after water turns into ice, there is not enough liquid water in the concrete to participate in the hydration reaction of cement, and the strength growth of concrete is very slow or even stops.

When the immersion vibrator is used for vibration, the thickness of each layer shall not be greater than 1.25 times the working length of the vibrator.

Reduce water consumption and concrete slump.

(2) When the side formwork is removed, the concrete strength shall ensure that its surface and edges and corners are not damaged..