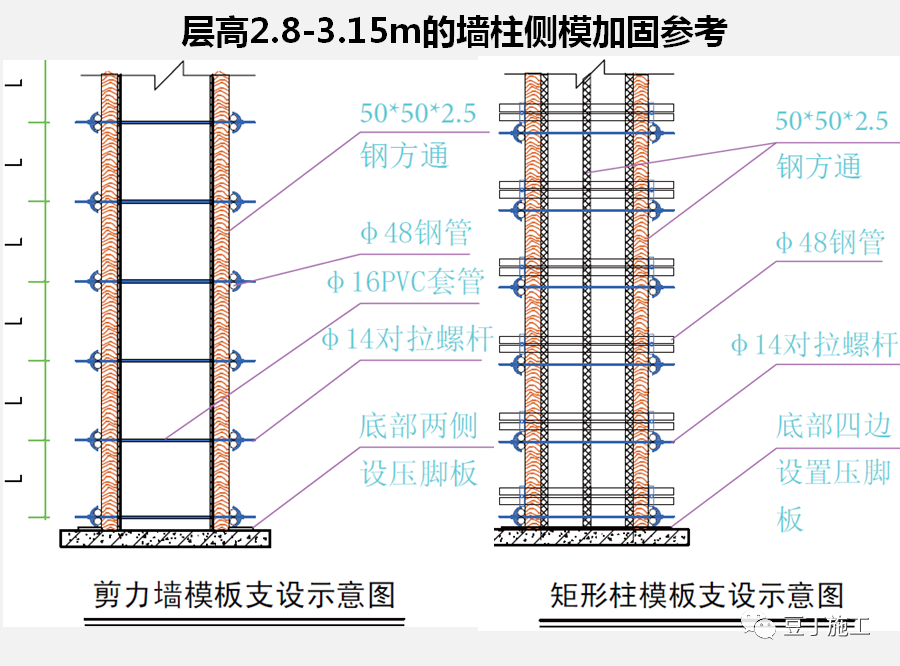

Promotion reasons: the sealing plate reinforcement of side formwork such as shear wall and frame column in formwork engineering is not standardized, and there is a phenomenon of “Jerry building” to varying degrees, which seriously affects the forming appearance of concrete structure.

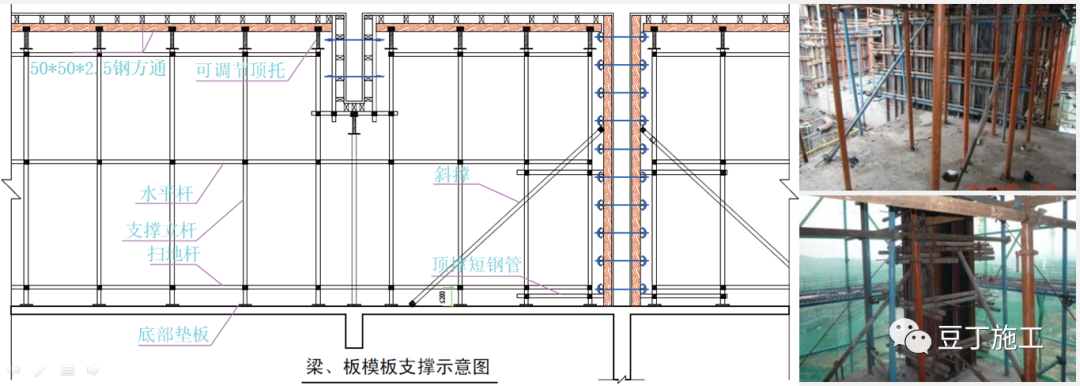

The length of the internal shear wall is ≥ 50cm, the steel pipe symmetrical diagonal bracing is adopted, the diagonal bracing spacing is ≤ 2m, the distance from the wall column edge is ≤ 50cm, and the reinforcement support point is reserved on the floor; 3.

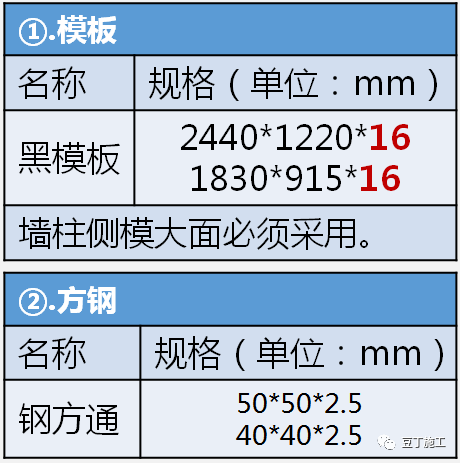

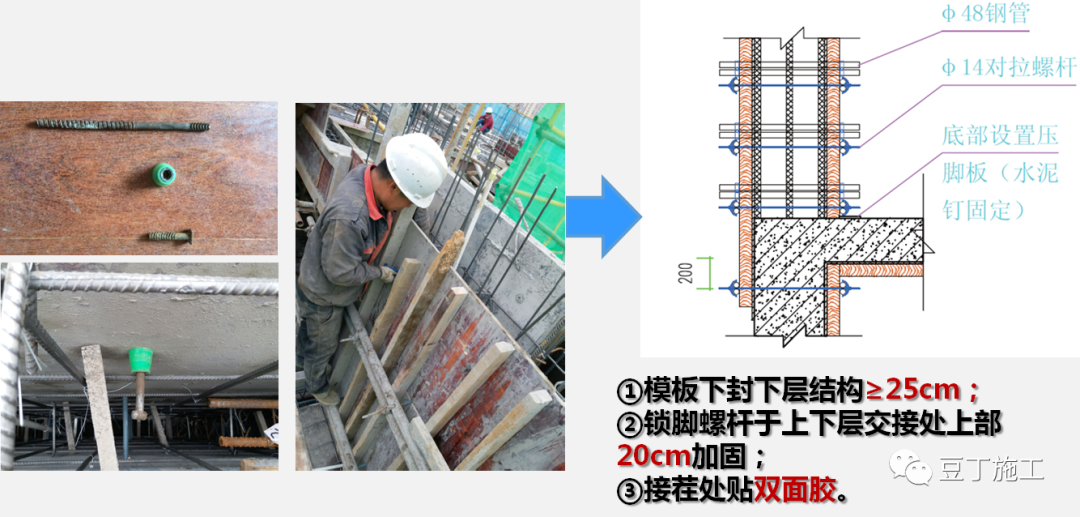

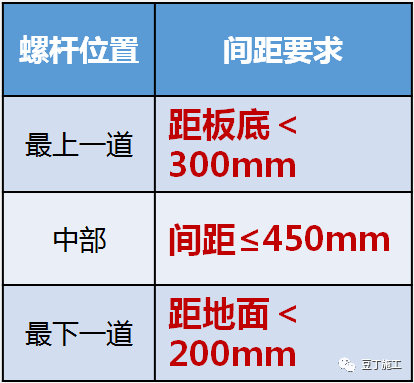

Process points 1) material 2) screw spacing ① 6 screws shall be set for wall columns with a floor height of 2.8-3.15m; ②.

2.

3、 Wall column side formwork reinforcement process 1.

2.

Each user can set frequently read subscription numbers, which will be displayed in the form of large cards.

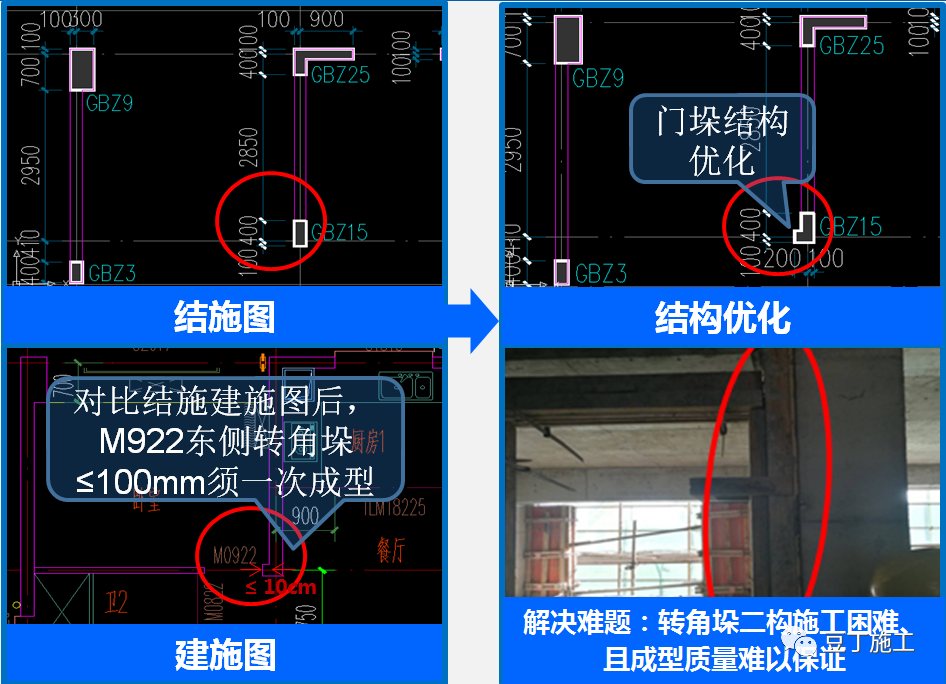

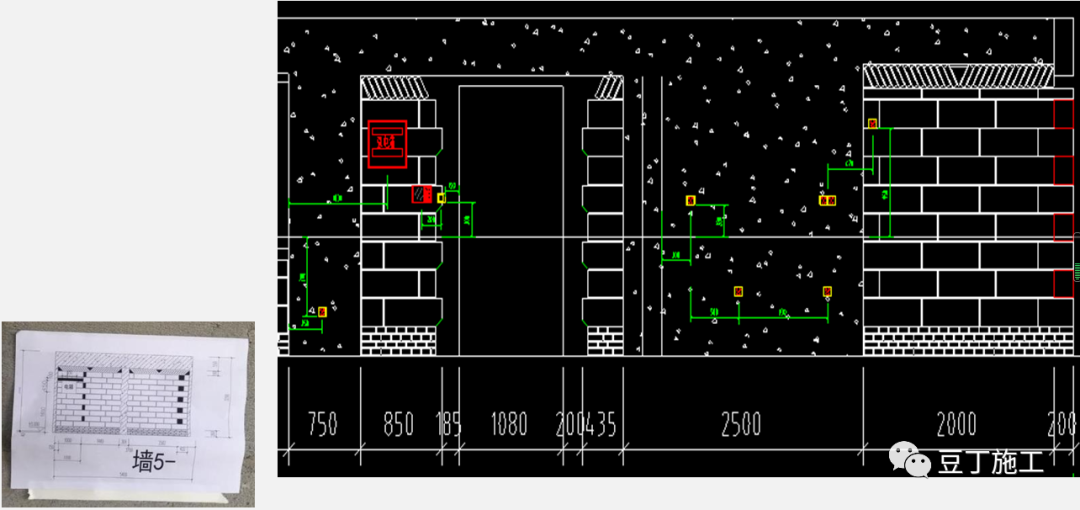

Review and mark the door, window stack and corner stack with size ≤ 10cm; 3.

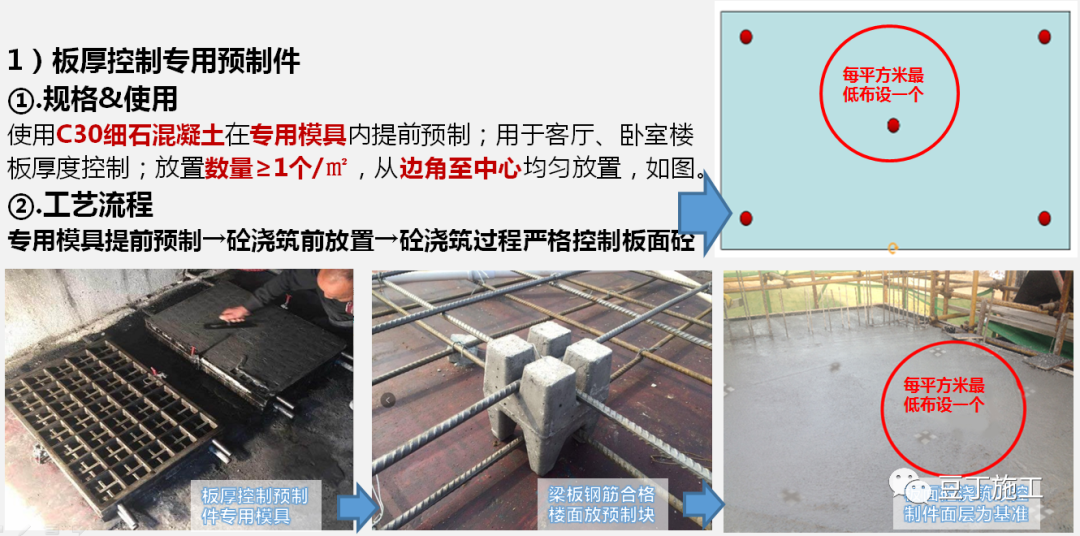

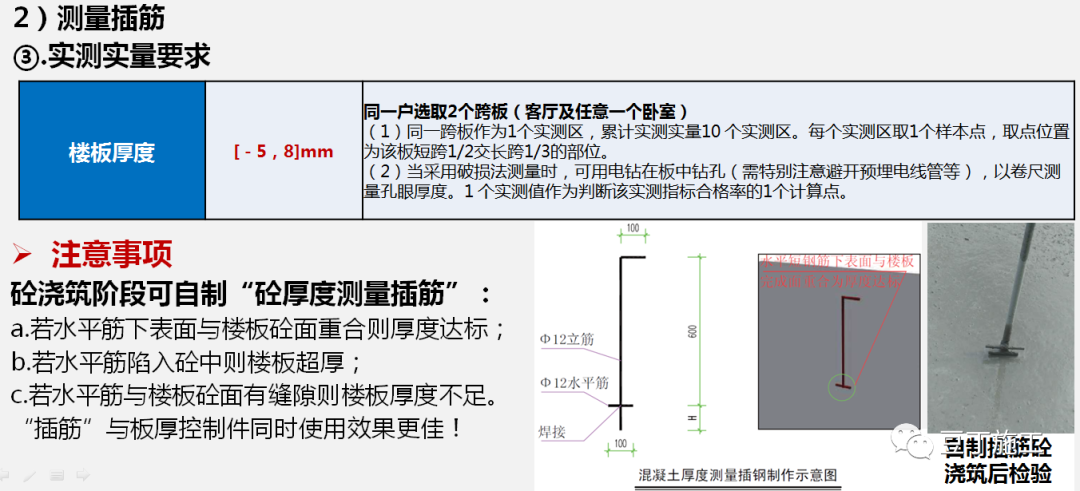

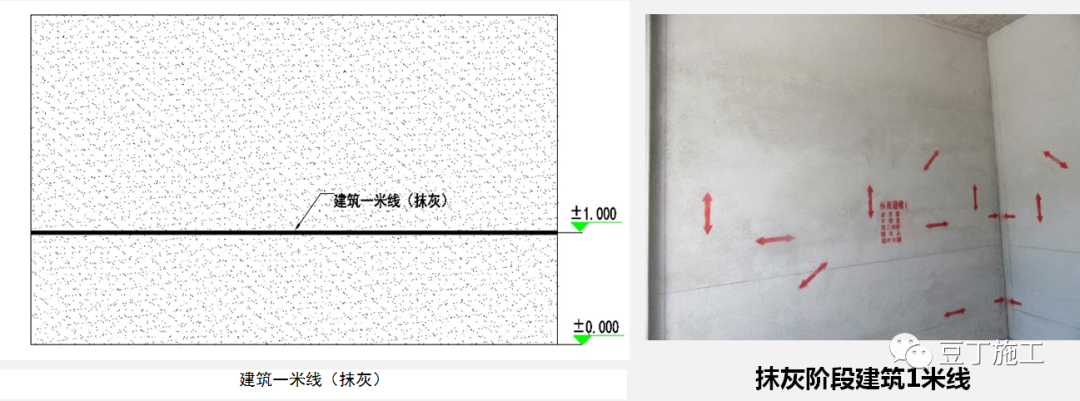

4、 Floor thickness control process 1.

Promotion reasons in concrete engineering, the thickness of structural floor affects the overall safety performance of the structure.

The slab thickness is too large, which increases the self weight of the structure; The floor thickness is too small, which greatly affects the strength and stiffness of the floor.

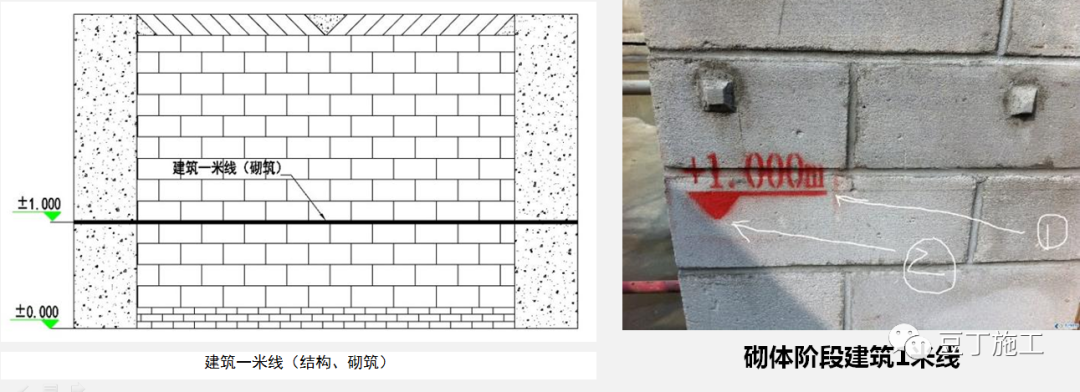

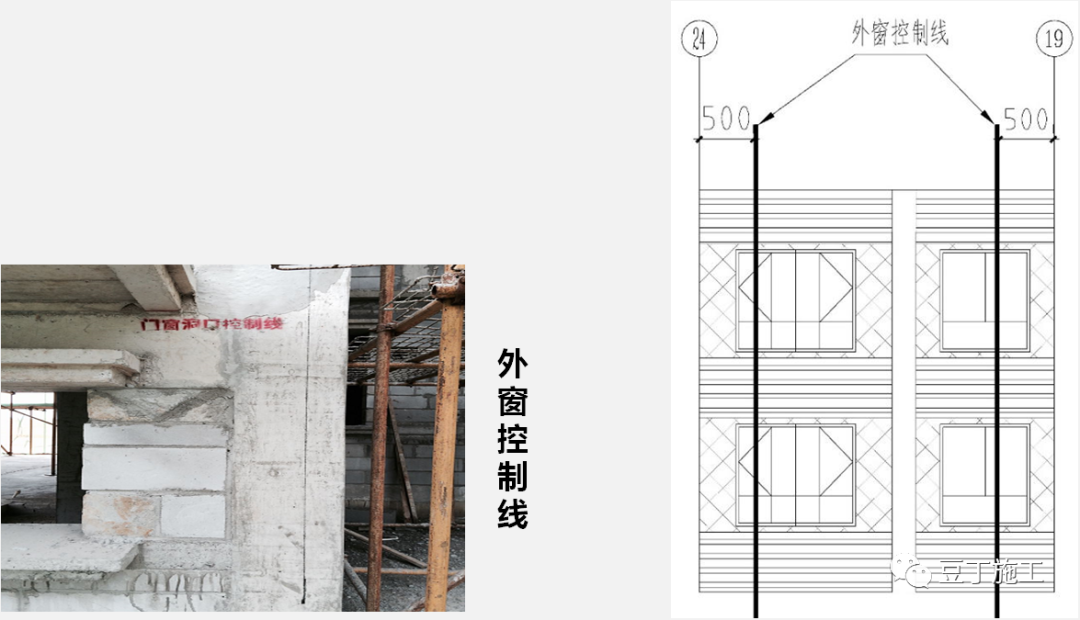

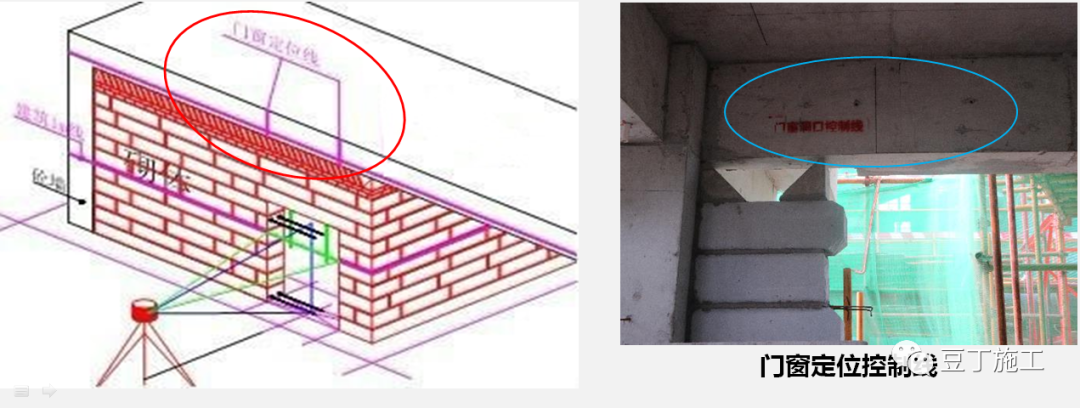

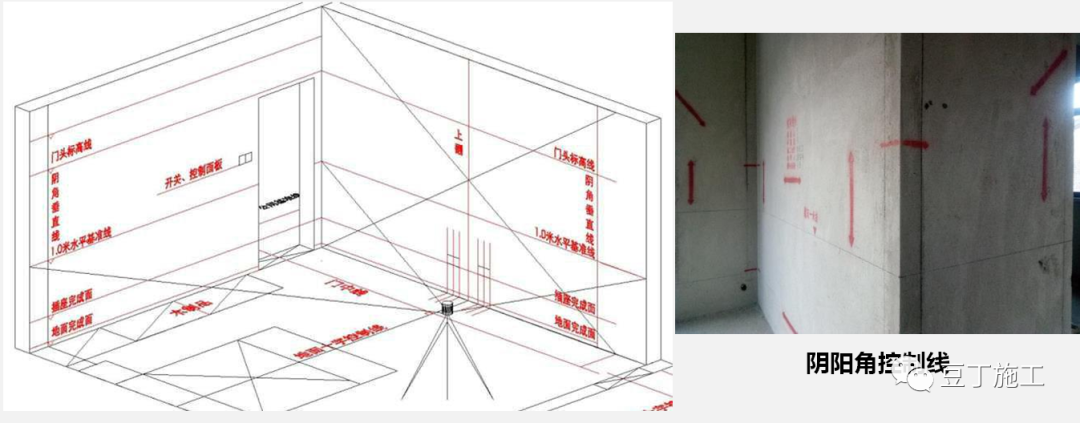

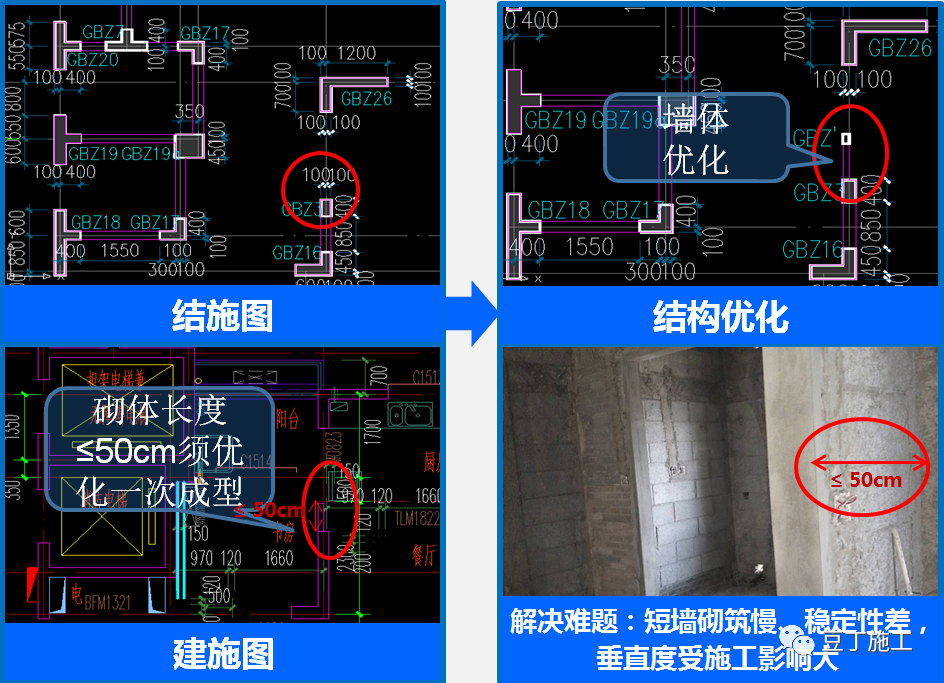

Promotion reasons 1) masonry, door and window layout concept in the masonry stage, the layout drawing accurately marks the positions of secondary structures, doors and windows according to the hardbound drawing to ensure the hardbound quality 2) masonry, door and window layout function masonry, door and window layout must optimize the assembly method and accurately identify the secondary structures The optimization of door and window openings, the size and position of top brick guide wall and embedded parts can effectively ensure the firm installation of aluminum window railings, ensure the overall strength and stability of masonry infilled wall, and ensure that the positions of doors, windows and water and electricity points are conducive to fine decoration construction.

3.

Therefore, if you do not want to miss the article “standardization of project management”, you must do the following: enter the official account of engineering management standardization > click the menu in the upper right corner and choose “star standard”.

masonry, door and window layout control process 1.

must be marked and explained; After the project sends the contact list to the area for review and approval, the large-scale construction shall be carried out.

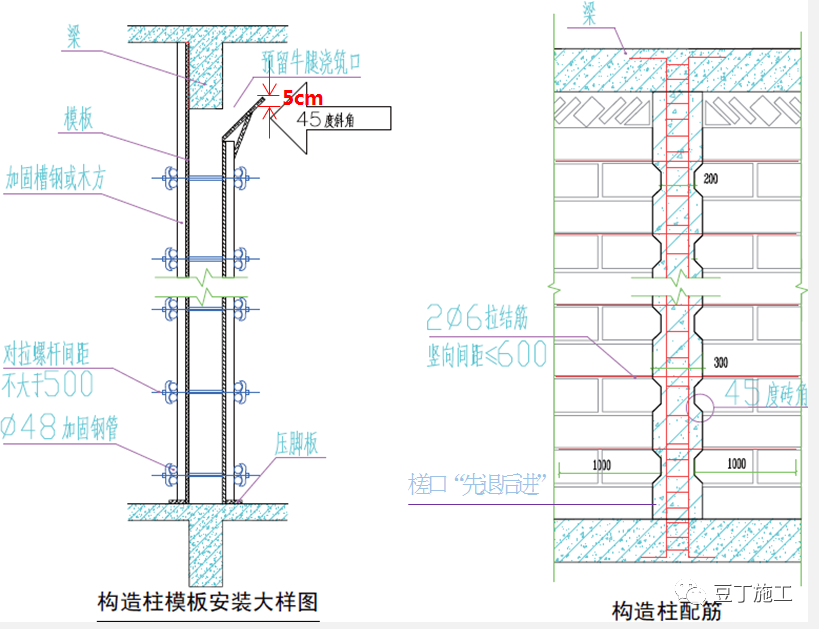

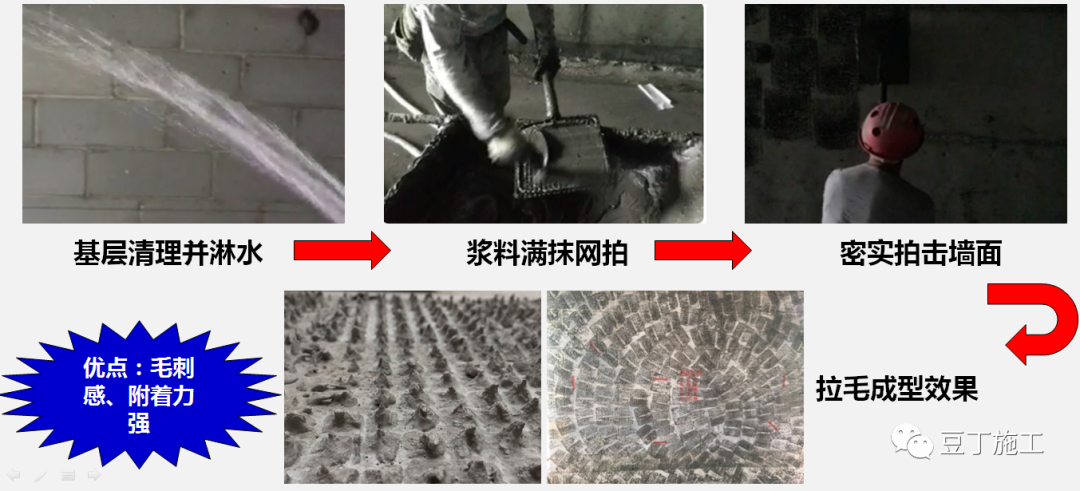

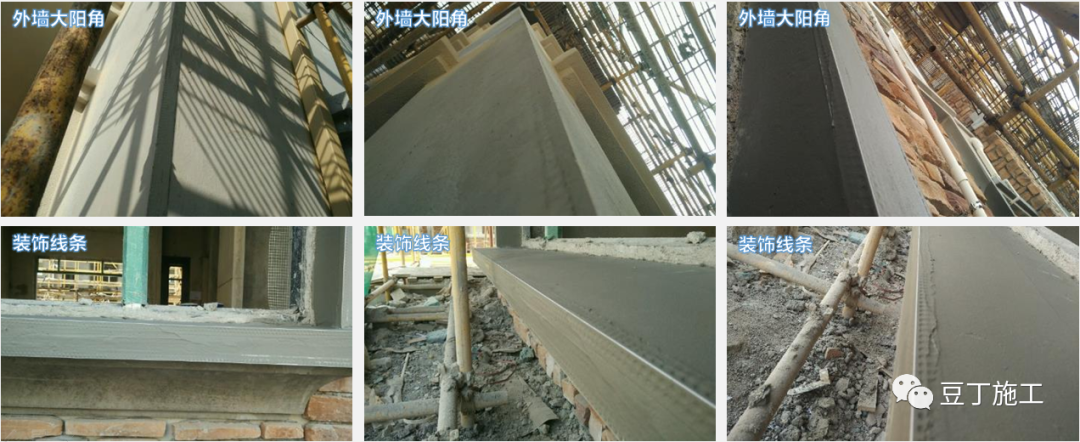

Promotion reasons 1) poor forming and difficult formwork erection.

The specific screw spacing requirements are as follows: 3) diagonal brace ① The external wall column adopts the combination of pull and top, and the reinforcement pull node is embedded on the floor.

It is optimized to form the structure at one time and lay structural reinforcement (the same as the reinforcement setting of frame holding column).

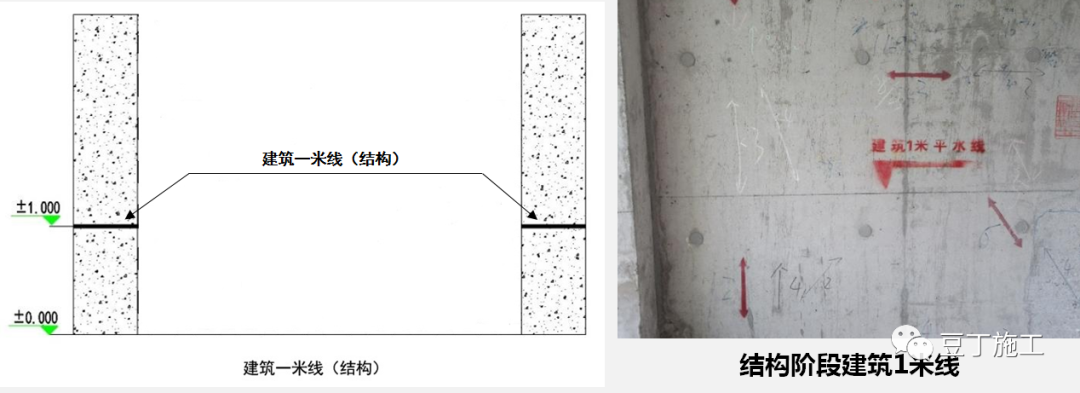

Check the structural construction and building construction drawings; 2.

The formwork erection of secondary structures such as corner structural column, 100 wall door stack holding frame and door lintel in masonry engineering is very difficult, and the molding quality of most bid sections in Anhui area is poor.

At this stage, the forming quality of concrete sill in some bid sections is poor, and the cracking, damage, formwork expansion, deviation and size do not meet the requirements are common, which has a great impact on the later masonry construction, as well as the hidden dangers of root leakage and moisture return.

Promotion reasons according to the group’s mandatory requirements, concrete sill such as toilet, sun terrace and roof parapet root must be formed at one time with the structural floor slab on the same floor (the forming height shall be subject to the drawing and two prevention requirements).

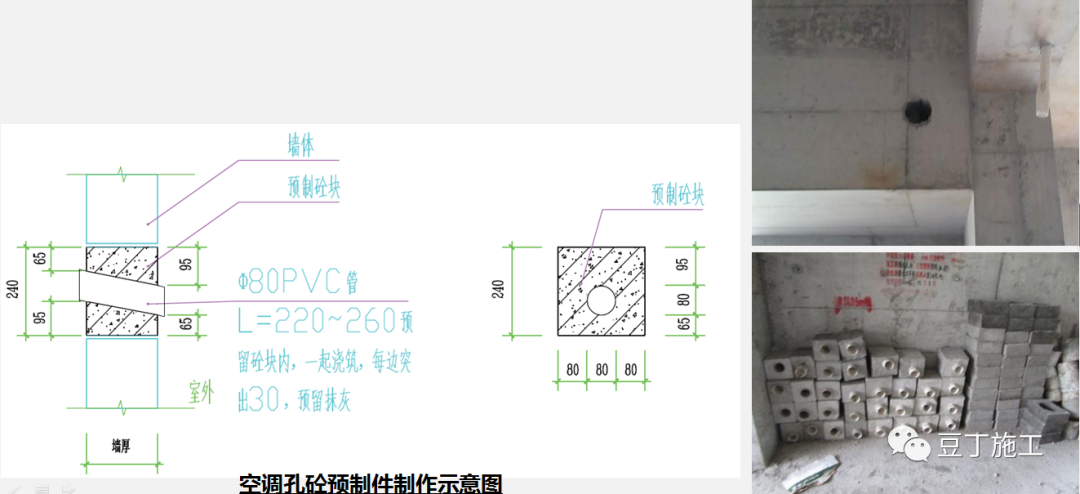

Precautions 1) toilet water supply pipe I Install the toilet water supply pipe around the sill II The secondary and secondary structure optimization process of aluminum profile with 80 * 50 * 3 pressure groove of wall water supply pipe 1.

Fix with shaped square clamp or angle steel; Ⅲ.

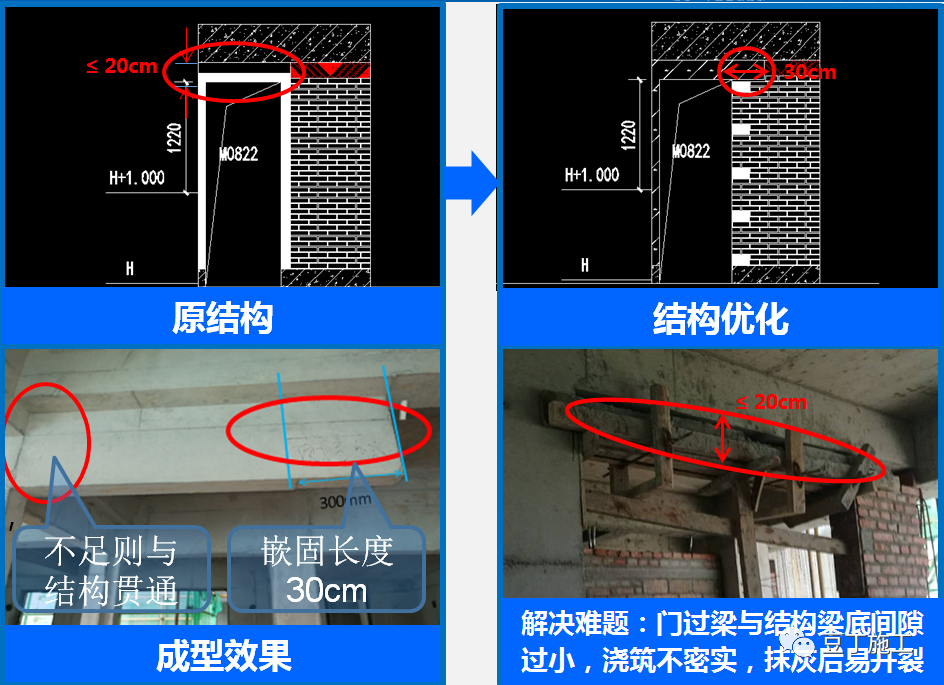

If it is insufficient, it will be connected with the structure to prevent “inverted eight” cracks.

2.

Key points of process 1) layout drawing before masonry construction, the physical layout drawing must be posted on the site.

Process key points 1) door stack, window stack and corner stack 1.

Angle steel cable-stayed reinforcement shall be used at the corner; Ⅳ.

2.

The cable-stayed / top spacing is ≤ 2m, and the distance from the wall column edge is ≤ 50cm; ②.

Editorial department telephone: 01088083186 warm reminder: Recently, WeChat official account information flow is revised.

Check the structural construction and building construction drawings; 2.

Review and mark masonry walls with size ≤ 50cm; 3.

formwork process for sill finalization 1.

3) Hang 1 under the door lintel and check the structural and architectural drawings; 2.

Precautions 1) the following formwork erection methods shall be adopted for the formwork at the joints between the upper and lower layers of the structure: 2) when the height of the beam web is ≥ 450mm, another split screw shall be set at the junction with the wall column, and 3 beams shall be set in the beam with a spacing of 500mm3) at the junction between the beam and the wall, the beam side formwork shall extend into the wall or the wall formwork shall extend into the beam ≥ 300mm.

It is optimized to form the structure at one time and lay structural reinforcement (the same as shear wall).

Note: the embedded length is 30cm.

2) Masonry short wall 1.

The internal bracing of the sill shall be reinforced with angle steel, with no less than 1 in the rectangular direction and no less than 4 in the short direction.

2.

In the drawing, the height of guide wall top brick, the number of masonry sheets, the position and size of concrete prefabricated parts, the position and size of secondary structure, the position and size of door and window holes, water and electricity points, etc.

Source: Baidu Library, country garden Anhui area, Douding construction structure stage (process 4 items) I.

The reinforcement is not firm, the stiffness is insufficient, and the concrete structure is prone to distortion and formwork expansion, resulting in poor measured data; The sealing plate is not tight, the slurry leakage prevention measures and vibration are not in place, and the concrete structure is prone to rotten roots, honeycombs, holes, exposed reinforcement and other phenomena, thus affecting the structural safety.

Adopting secondary structure optimization to one-time forming of structural engineering can greatly reduce the difficulty of formwork erection process and improve the forming quality of secondary structure.

2) reinforced concrete frames / frame columns shall be set on both sides of the secondary structure fire doors and windows and entrance doors; When the opening width is ≥ 2.1m (subject to the drawing design), structural columns shall be set on both sides of the opening..

Process key points 1) material requirements: Aluminum formwork or steel formwork must be used for hanging formwork installation of toilet sill 2) detailed installation requirements: I The height of finalized formwork shall be ≥ 220mm to avoid insufficient forming height of sill due to installation deviation; Ⅱ.

4) The railing line is fixed, and the railing line is optimized to be 150mm wide to facilitate the later railing installation and closing.

Key points of process masonry stage (3 items of process) v.

Where the distance from the bottom of the structural beam to the bottom of the door opening beam is ≤ 20cm, it is optimized to form the hanging beam under the structure at one time and lay the structural reinforcement; 3.