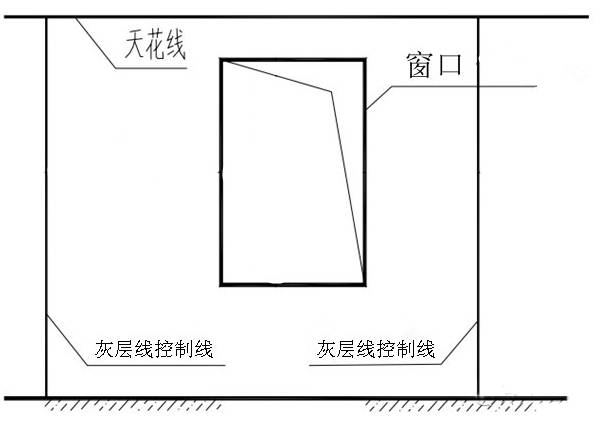

As shown in Figure 8 below, the bottom of the plastering layer should generally be plastered after about 2h of the completion of the screeding.

Generally, the width of standard reinforcement is 5cm.

Transverse reinforcement should be made when it is greater than 3.5m, and the spacing of ash cake should not be greater than 2m.

3.

It must be ensured that the scraping ruler can scrape more than two ash cakes at the same time during plastering.

Vertical hanging, square setting, plastering cake and screeding: hang the vertical at the corners of doors and windows, stacks and walls respectively, and the horizontal line is controlled by the floor as the horizontal baseline or + 50cm elevation line, then set the square plastering cake and screeding based on the ash cake.

Plastering cake and screeding as shown in the following figure: the ash cake should be made into 5cm square, and the distance between the two ash cakes shall not be greater than 1.2 ~ 1.5m.

100 on each side of the joint, and the interior wall decoration can be carried out only after the treatment); If the total thickness of external wall plastering is greater than 50, it is required to hang it with full nails Φ four point zero two × one hundred and fifty × 150 steel mesh and effectively connected with the main body.

Then scrape and straighten with a large bar, and rub with a wooden trowel.

The laying width on each side shall not be less than 150.

10.

Then, comprehensively check whether the bottom ash is flat, whether the internal and external corners are square, straight and tidy, whether the junction between the rear of the pipe and the internal corners and the junction of the wall and roof are flat and straight, and check the verticality and flatness of the wall with the line support plate.

After the initial setting of the plastering mortar plastering surface, it shall be watered for curing in time, and the curing time shall not be less than 5 days..

The hanging net shall be hung according to the design requirements.

Machine spray 5% 108 glue mixed with water or other interface treatment agent on the base course to form a shotcrete surface, which can be solidified on the smooth base course surface and can not be broken by hand.

The second construction can be carried out after the first initial setting.

When the wall height is less than 3.5m, vertical bars should be made.

If there are special local requirements, the reinforcing net shall be fully hung.

Plastering shall be carried out in layers.

Steel wire brush shall be used to remove laitance, release agent, oil stain and formwork residue on the surface of concrete wall, cut off exposed reinforcement head and chisel protruding concrete block; Clean the dust on the masonry wall, and remove the laitance and protruding mortar blocks on the wall.

When plastering the cake, the correct position of the cake shall be determined according to the indoor plastering requirements, and then the ruler board shall be used to find the vertical and flat.

At the same time, strengthen the inspection and acceptance of shotcrete quality.

5.

Figure (III) repair and plastering of reserved holes, distribution boxes, grooves and boxes: after the bottom ash is plastered, a specially assigned person shall scrape off the 5cm wide lime sand around the reserved holes, distribution boxes, grooves and boxes, remove it, wet the periphery with water with a large brush, and then press and plaster the periphery of holes, boxes, grooves and boxes with cement mortar.

Dp-m5 cement mortar shall be used for priming and leveling, which shall be survived in two times, and the thickness of each time shall be controlled at 5-7mm.

Reinforcing mesh shall be hung at the junction of different material substrates, on the substrate of concealed pipeline holes and grooves, and on the leveling layer with a total plastering thickness of ≥ 35mm; 300 wide galvanized welded steel wire mesh shall be hung at the junction of reinforced concrete beam, column and brick wall of inner wall φ zero point nine × twelve point seven × 12.7 cement nails shall be used for hanging.

The spacing between two bars shall not be greater than 1.5m.

Plastering mortar shall be directly fixed on the wall to prevent temperature change and uneven shrinkage from causing cracks in plastering (Galvanized electric welding steel wire mesh shall be nailed on both sides of slotting) Φ one point zero seven × twenty-five × 25.

During operation, the ash cake shall be plastered first, and then the ash cake shall be plastered down.

When plastering the bottom ash, use a soft scraper to scrape it smoothly, and use a wood trowel to rub it flat and rough.

If there are no design requirements, it can be hung according to the current specifications.

A layer of mortar shall be scraped on the cleaned and protected wet base course, and the construction shall be carried out in two parts.

Do not spray water directly with water pipe.

In addition, this square control datum line must be used for each room in the same floor of the same suite, and then it shall be used as the benchmark to survey to each room; The squareness control line shall be snapped within 30-60cm from the wall, and obvious identification and protection shall be made.

It is recommended that the surface is not rough, there are no obvious small pits and the sand head is not exposed.

The shotcrete area shall not be less than 95% of the surface area of the base course.

4.

Internal wall plastering process: substrate treatment → hanging reinforcing mesh → straightening, square setting, plastering cake and setting standard reinforcement → interface treatment → corner protection → snapping ash layer control line → plastering bottom ash → plastering surface ash → curing.

When wetting wall is needed, spray the water to damp the masonry surface and spray the water evenly at the base.

If the masonry surface is dry, it shall be watered first, brushed with a layer of plain cement slurry, followed by plastering the surface ash, scraping (flat with the dividing strip or ash cake surface) and roughening with a wooden trowel.

The surface course mortar can be plastered the next day after the base course mortar is plastered.

Curing: curing shall be carried out 24 hours after construction, and the curing time shall be 3-5 days under normal temperature.

When the concrete surface exceeds the finished plastering surface, the excess part shall be chiseled to ensure that there is at least 7mm plastering layer.

For base course treatment, plaster mortar or fine aggregate concrete shall be used to repair scaffold holes, including cantilever I-beam and scaffold holes.

The number of reinforcement shall be determined according to the width and height of the room.

It should be noted that the scraping can be carried out at 90 degrees cross, and the scraping shall be fully paved and compacted.

It shall be installed in layers, plastered and leveled with the screeded reinforcement.

In order to avoid and reduce the mortar hollowing and shrinkage cracks of the plastering layer, the surface layer should not be pressed too much.

After the surface mortar surface receives water, it shall be compacted and polished with an iron trowel.

As shown in Figure 7 below, the plastering layer control line is popped on the wall after the plastering layer control line is reinforced.

The wetting depth of autoclaved aerated concrete masonry should be 10 to 15mm, and its moisture content should not exceed 20%.

The moisture content of ordinary concrete small hollow masonry and lightweight aggregate concrete small masonry should be controlled at 5% ~ 8%.

Set square: a square control datum line must be set in the same floor of each suite, which shall be set as long as possible to reduce the survey error.

The plastering thickness of surface mortar shall be controlled within 5-8mm.

6.

The plastering process can only be started 21 days after the completion of wall masonry or 14 days after the completion of inclined brick top masonry.

When the mortar of ash cake reaches 70% dry, the same mortar as the plastering layer can be used to fill the reinforcement.

2 external wall plastering process: substrate treatment → hanging steel wire mesh → hanging line, pasting ash cake and setting standard reinforcement → interface treatment → snapping ash layer control line → plastering bottom ash → plastering surface course → maintenance.

9.