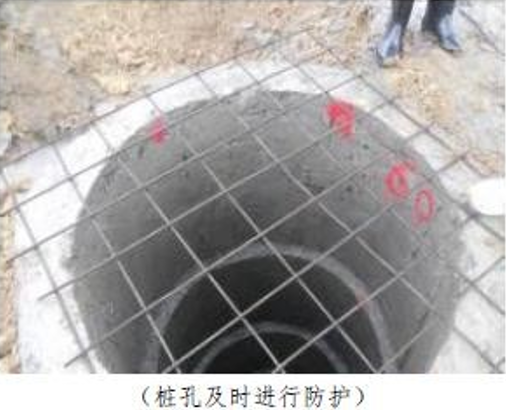

In the well hole where no one works, well covers and warning signs should be set to prevent people from falling into the well hole.

After the pile hole retaining wall of each section is completed, the cross axis and elevation of the pile position must be measured at the upper opening of the retaining wall, then align with the cross line, drop the hanging line to the hole bottom, and check the vertical flatness of the hole wall with a radius ruler.

Your support is my motivation.

If you have any questions or want to share, please comment in the message area! I will make periodic summary on a regular basis, and build the official account: Engineering Blog into a database of the engineering industry for all to share.

After the pile position line is set, it must be rechecked by relevant departments and excavated after the pre inspection procedures are completed.

When the diameter of the pile hole is small, the depth is shallow and the soil quality is good, and the soil layer above the groundwater level can also be protected by shotcrete.

Hemp rope and nylon rope shall not be used to hang or pedal up and down the shaft wall flange.

Install the bucket, lighting, movable cover plate, water pump or fan (1) when installing the pulley block and bucket, pay attention to make the bucket coincide with the center of the pile hole as the center line of the pile position and the retaining wall formwork during excavation.

The slump of concrete shall be controlled at 100mm.

Excavate the earthwork of the first section of pile hole, excavate the pile hole layer by layer from top to bottom, excavate the earthwork of the middle part first, and then expand to the periphery, so as to effectively control the section size of the excavated pile hole.

(4) when the underground water volume is not large, the muddy water shall be transported out with buckets at the same time of excavation..

Check the axis and elevation of the pile position (Center).

Determine the center of the pile position, take the midpoint as the center of the circle, and draw the upper circumference with the radius of the pile body plus the thickness of the retaining wall as the radius.

(3) before starting work every day, toxic and harmful gases must be detected underground, and sufficient safety precautions shall be taken.

(3) the wall protection formwork shall be removed 24 hours after pouring concrete; When honeycomb and water leakage are found on the retaining wall, it shall be reinforced in time.

The formworks are connected and fixed with fixtures and fasteners, or an arc-shaped inner steel ring made of channel steel or angle steel can be set at the upper and lower ends of each section of formwork as the inner support to prevent the deformation of the inner formwork due to tension.

When it rains, special personnel shall be assigned to dredge and drain to prevent rainwater from overflowing the retaining wall and entering the hole.

The hole depth must be measured one by one based on the datum point.

2.

Setting out, pile location and elevation of construction process determine the grid control network and elevation datum point of pile location axis on the basis of three supplies and one leveling of the site and according to the data of building survey control network and foundation layout plan.

(3) the deviation between the center line of the first section of well ring retaining wall and the design axis shall not be greater than 20mm; The top surface of the well ring shall be 100 ~ 150mm higher than the site for soil and water retaining, and the wall thickness shall be increased by 100 ~ 150mm compared with the thickness of the shaft wall below.

Drainage ditches must be dug at the construction site.

It is not suitable for alluvial land with quicksand, high groundwater level and large water inflow and silt or muddy soil layer with high water content in modern sedimentation.

(2) the retaining wall formwork shall be reused by removing the upper section and supporting the lower section.

Ensure that the position, elevation and section size of pile hole axis meet the design requirements.

Special scheme shall be prepared for manual hole digging pile, and experts shall be organized to demonstrate if the depth exceeds 16m.

When the excavation depth of pile hole exceeds 10m, there shall be special equipment for underground air supply, and the air volume shall not be less than 25L / s.

Guardrails must be set around the hole, and the height of guardrails should be 0.8m.

This paper introduces the third part.

The lime line shall be used as the dimension line of pile hole excavation.

The height of each section shall be determined according to the soil quality and operating conditions, generally 0.9-1.2m.

Pour the first section of wall protection concrete (1) concrete shall be poured immediately after each section of pile hole wall protection concrete is excavated.

No horizontal support is set to facilitate operation.

Please pay attention to the original documents after 👇 Message area 👇 Leave your email! The main contents include: prestressed pipe pile, bored (punched) cast-in-place pile, manual hole digging pile, CFG} pile, pile foundation detection and application of new technology, which are divided into five parts.

(4) the axis and elevation of pile position shall be calibrated at the upper opening of the first section of retaining wall.

(4) the range difference of any diameter of the well ring on the same horizontal plane shall not be greater than 50mm.

Process flow 3.

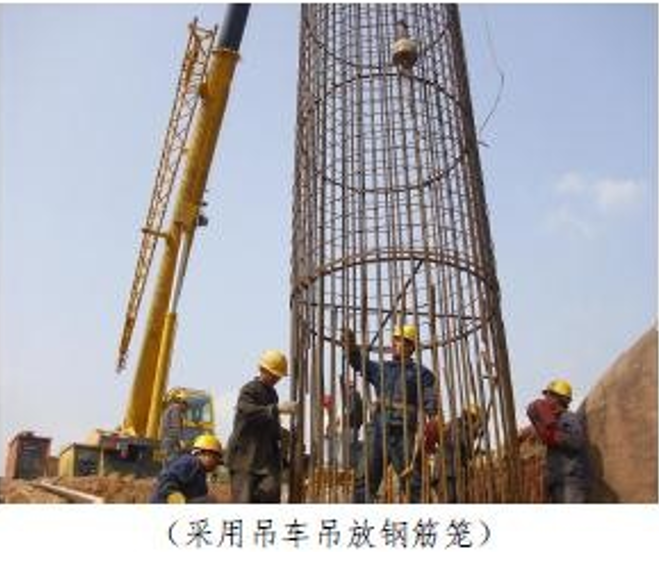

Install electric hoist or winch, install pulley block and electric hoist or steel wire rope passing through the winch on the vertical transportation frame, and select an appropriate position to install the winch.

Supports include: wooden support, steel pipe hanger, wooden hanger or I-steel guide rail support, which shall be erected stably and firmly.

Reinforcement binding for supporting and protecting wall formwork (1) in order to prevent pile hole wall collapse and ensure safe construction, protective wall shall be set for hole forming, including long steel casing and cast-in-situ concrete.

The cast-in-situ reinforced concrete retaining wall can be closely combined with the soil wall, with good stability and overall performance, and uniform stress, so it can be selected preferentially.

The Xiaobian will do everything in its power to add it.

What information can be checked, and what information is there? Leave a message.

After the first pile hole of the vertical transportation frame is completed, the vertical transportation support shall be erected at the upper opening of the pile hole.

Push button switch should be used for electric hoist, and its safe lifting capacity must be checked before use.

(2) the hole bottom lighting must use low-voltage power supply (36V, 100W) (no more than 24V in case of water) and safety lamps with waterproof covers.

Emergency soft ladder must be set in the hole for personnel to go up and down; The electric hoist and cage used shall be safe and reliable, and shall be equipped with automatic clamping safety device.

(sorry that the last Title serial number was not modified ······························································································································.

(2) each section of retaining wall shall be constructed continuously on the same day; The wall protection concrete must be vibrated tightly, and the accelerator shall be used according to the water seepage of the soil layer.