2.

The construction period is slightly longer and the floor weight is large.

of the original structure (independent support is required for non load-bearing structure or can not meet the construction of the original structure, but the independently supported components also need to be made on the load-bearing beam and other components).

When welding the supporting plate or connecting plate, it shall be welded by section.

The main beam can be loaded only after all anchor bolts are solidified.

Method 1: steel structure cement pressure plate composite floor method: secondary beam purlin (spacing about 600mm) + cement fiber board (or OSB Orson board) + about 40mm thick fine stone light concrete (optional) + decorative surface layer; This structural scheme has the advantages of low cost, light weight and short construction period; It is applicable to the mezzanine transformation of civil residential buildings, office buildings and industrial projects; When there is a large floor load or vibration load, choose carefully, because according to the technical specification for light steel structure residence (jgj209-2010), such floors and wallboards have been clearly prohibited: Method 2: steel structure concrete composite floor method: steel structure floor support plate + about 100mm thick reinforced concrete plate + decorative surface layer; This scheme has the characteristics of high safety performance, large load, no vibration and good sound insulation effect.

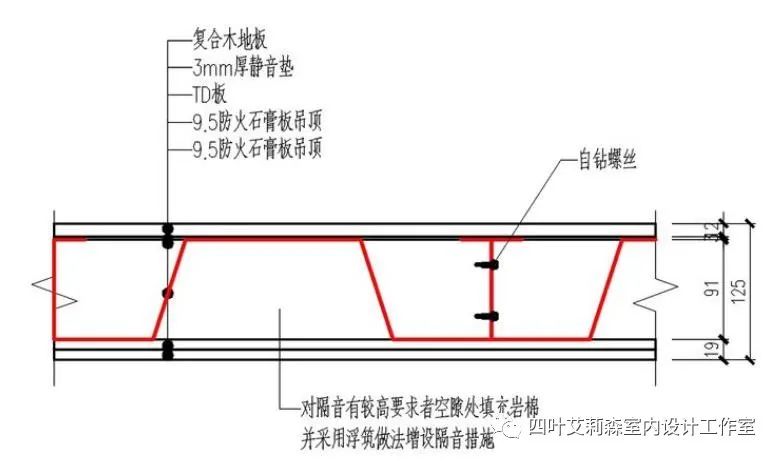

When the span is less than 3.3m, the overall thickness of sandwich floor is only 125mm.

In the case of conventional span, the overall thickness of td-loft sandwich floor is 120mm.

If there is a gap between the embedded plate and the concrete beam or concrete column, it can be treated with glue or grouting material.

The rotating speed during implantation cannot be too fast, which will cause incomplete drug mixing, and too slow will cause drug running, which will reduce the pulling force.

This structural combination scheme has the advantages of low cost, good bearing effect and fast construction, effectively solves the effects of thermal insulation and sound insulation, and has a wide range of application.

When drilling, try not to interrupt the main reinforcement, and turn the hole in strict accordance with the depth and diameter required by the process, Anchor bolts shall be configured according to roof load.

If the foundation of a tree is good and the trunk can not bear external forces, it is in vain.

For the fabrication of embedded plate, the embedded plate is a couple of anchor bolts.

Even after it is disconnected outside, it is easy to enter the connection, and the machinery can not be used.

After the steel beam is selected, it shall be polished, derusted, cut and primed, After arriving at the site, the anchorage at both ends shall be measured for fine cutting.

If the span is small, I-beam or H-section steel can be selected.

Method 4: td-loft sandwich floor system method: corrugated steel plate with innovative patent is used as the stress component, integrating various functions such as decorative surface layer, waterproof, fire prevention, sound insulation and so on.

Common practices of loft mezzanine floor slab 1 Td-loft ultra thin interlayer, with a thickness of only 9cm ~ 12cm, increases the comfort of residents.

The main beam of the main beam is the second key to safety in the steel structure sandwich project.

New steel structure sandwich floor 1 Load A.

The steel structure loft compartment is in the form of building steel structure composite floor slab in the floors of residential buildings, office buildings, factories, venues and other buildings with high clear height, so as to change the first floor into two floors, that is, make rational use of space and increase the use area without damaging the appearance of the original.

b.

After manual lifting and splicing, it is connected by hoisting the steel beam.

Steel beam + checkered steel.

firstly, determine whether the fixed point is a load-bearing structure, and secondly detect the hardness, thickness, reinforcement, etc.

During installation, pull-out test shall be carried out for anchor bolts, and soil method test can be carried out for those with small shear force.

The thickness and area of the embedded plate shall be calculated according to the total load of the main beam (the reinforcement anchor plate shall be larger than the high-strength bolt anchor plate, in order to make up for the low success rate of the value reinforcement).

The loft compartment of steel structure has a variety of practices for different building types.

1.

It is applicable to different building patterns with large and small spans, such as residential buildings, office buildings, various plants, heavy load and vibration load floors, and has the widest scope of application.

Unlike other steel structures, the length of most beam purlins is variable, so the section steel shall be selected as far as possible if the span is small.

3.

This method has relatively large structural thickness and greater self weight.

It is the thinnest solution of floor mezzanine system at present.

The selection of the main beam is directly related to the bearing and span of the roof.

The construction of connecting steel structure interlayer is mainly the connection of steel beam, 1 welding and 2 high-strength bolt connection.

Method 3: steel structure light slab composite floor method: About 100mm thick ALC aerated concrete slab + about 30mm thick mortar leveling layer + decorative surface layer; This structural combination scheme has the advantages of safety and environmental protection, light weight, high strength, long-lasting and no deformation, fast construction, short construction cycle, good thermal insulation and sound insulation effect, and can also be as high as the upper flange of the steel beam during installation, so as to maximize the use of effective space.

Wet operation is required during operation, and the cost is relatively high.

The hole must be cleaned before the anchor bolt is implanted, otherwise the anchorage strength will be seriously affected.

Steel beam + cement fiber board: the cement pressure board in this method is brittle, thick and costly.

There are corresponding treatment schemes for edge trimming, toilet, tube well, staircase, sound insulation and embedded parts.

2.

3.

More drilling and less installation can be carried out, but it shall not be less than the design load.

When drilling all embedded plates, the situation of exploring reinforcement shall be considered.

It is the most advanced and effective loft floor practice at present.

The design and construction principles of the new sandwich floor are as follows: (1) comprehensively consider the use function, energy conservation and thermal insulation, sound and noise reduction, environmental coordination and other factors, and select the appropriate sandwich floor form..

The construction can be carried out after the implantation according to the temperature and waiting time.

However, the construction period is slightly longer and the floor weight is large, so it is not suitable for building additional apartments later.

Industrial projects with large floor load or vibration load shall be carefully selected.

Applicable to office buildings, residential buildings, light plants, etc; However, the construction speed is slow, the quality of ALC is uneven, and it is easy to be damaged.

In large projects, high-strength bolts are generally used for connection or welding, because the site and welding power supply allow it.

In the steel structure sandwich construction site, the space is often narrow, and it is difficult for the main beam to enter.