g.

The normal temperature curing shall not be less than 7 days and nights, and the special concrete curing shall not be less than 14 days and nights.

During the removal, the crowbar shall be used to remove it from one side in sequence, and the sledgehammer or crowbar shall not be used to pry randomly, so as to avoid the damage of the edges and corners of the concrete.

It is not allowed to impact the formwork with heavy objects, and it is not allowed to set up scaffolds on the formwork for lifting, so as to ensure the firmness and tightness of the formwork.

Once deformation, movement or displacement is found, the pouring shall be stopped immediately, and the formwork shall be repaired and reinforced in time, and then the pouring shall be continued.

The cushion concrete must be vibrated and compacted, the surface must be flat, and it is strictly prohibited to dry the foundation soil.

Only for exchange and learning.

After each step is poured, it shall be stopped for 0.5 hours.

Construction process 2.

Construction method A.

All connection points must be bound.

The upper vibrator shall be inserted into the lower layer for 3 ~ 5cm, so as to avoid collision with embedded parts and embedded bolts as far as possible and prevent the displacement of embedded parts.

c.

After cleaning and pouring of cushion and foundation trench inspection, remove the surface floating soil and disturbing soil without ponding, and immediately carry out cushion concrete construction.

The thickness shall be the thickness of the design protective layer, and the spacing of cushion blocks shall not be greater than 1000mm (determined according to the design reinforcement diameter) to prevent common quality problems of exposed reinforcement.

Pay attention to the finished product protection of reinforcement, and do not collide with reinforcement arbitrarily, resulting in reinforcement displacement.

After the binding of formwork reinforcement and the construction of relevant disciplines are completed, the formwork shall be installed immediately.

After the binding of the upper and lower stirrups and positioning stirrups, the column joint bar shall be adjusted in place and temporarily fixed with a well shaped wooden frame, and then the remaining stirrups shall be bound to ensure that the column joint bar is not deformed and out of shape.

Prevent improper vibration or missing vibration due to too thick blanking.

After the pouring of reinforcement binding cushion is completed and the concrete reaches 1.2MPa, snap lines on the surface for reinforcement binding.

j.

After concrete curing, the poured concrete shall be covered and watered within about 12h.

e.

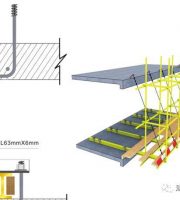

The height of each step of the stepped foundation shall be poured and vibrated as a whole.

In order to ensure the correct position of the reinforcement, a layer of 5-locm thick concrete shall be poured first to fix the reinforcement.

1、 Construction of independent foundation under column 1.

Clean and remove wood chips, soil and other sundries in the formwork, water and wet the wooden formwork, and block the slab joints and holes.

Concrete leveling after concrete pouring, the concrete with large surface shall be vibrated once with a flat vibrator, then scraped with a rod, and then rubbed with a wooden trowel.

Missing buckle is not allowed in reinforcement binding.

After the reinforcement is bound, plastic cushion blocks for the protective layer shall be placed on the bottom and side.

The hook part of column joint reinforcement must be bound at 45 ° with the bottom plate reinforcement.

The concrete pouring shall be carried out continuously in layers, and the interval time shall not exceed the initial setting time of the concrete, generally not more than 2 hours.

The two positioning bars must be replaced after the foundation concrete is poured.

The formwork shall be small steel formwork or wood formwork, which shall be reinforced by shelf pipe or wood.

The foundation form of the project is stepped foundation.

The immersion vibrator shall be used for concrete vibration, and the insertion distance shall not be greater than 1.5 times of the action radius.

d.

During concrete pouring, the formwork, support, reinforcement, bolt, reserved hole and pipe shall be regularly observed for movement.

f.

Before receiving, the concrete surface elevation must be checked, and those that do not meet the requirements shall be rectified immediately.

After it sinks, another layer shall be poured.

The first stirrup shall be bound 5cm away from the bottom plate and the last stirrup shall be bound 5cm away from the foundation top as elevation control reinforcement and positioning reinforcement, A positioning bar shall be bound at the top of the column joint bar.

h.

The material is cut in layers, and the thickness of each layer is the effective vibration length of the vibrating rod.

i.

If there is infringement, please contact to delete..

b.

The maintenance shall be checked and implemented by special personnel to prevent cracks on the concrete surface due to untimely maintenance.

Before the removal of the formwork, a special person shall be assigned to check the concrete strength.

The side formwork can be removed only when the concrete strength can ensure that its edges and corners will not be damaged due to the removal of the formwork.