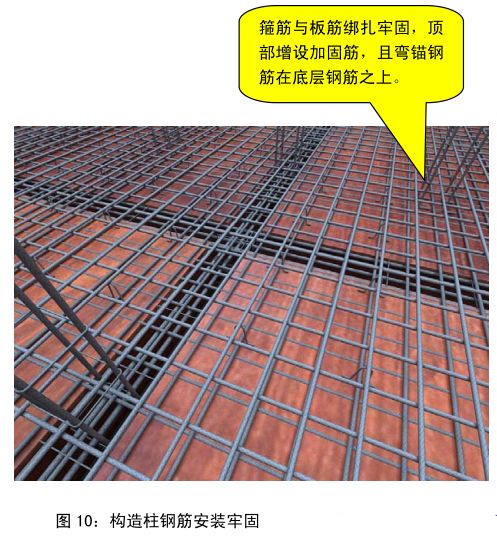

The joint bar of structural column shall be bound firmly with the reinforcement of beam and slab.

3.

The cement support and wall reinforcement shall be bound firmly with binding wire, and the spacing shall not exceed 80cm.

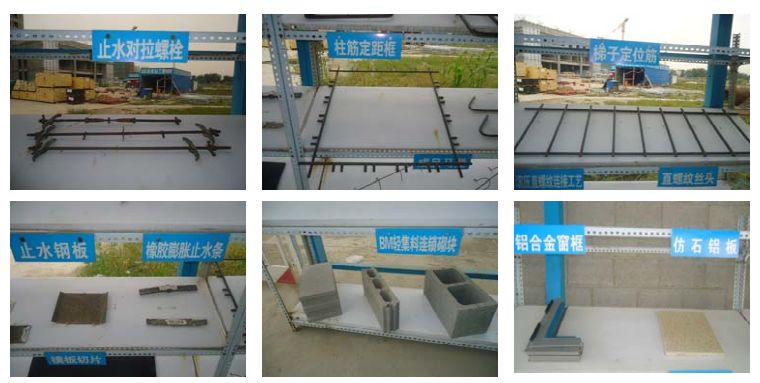

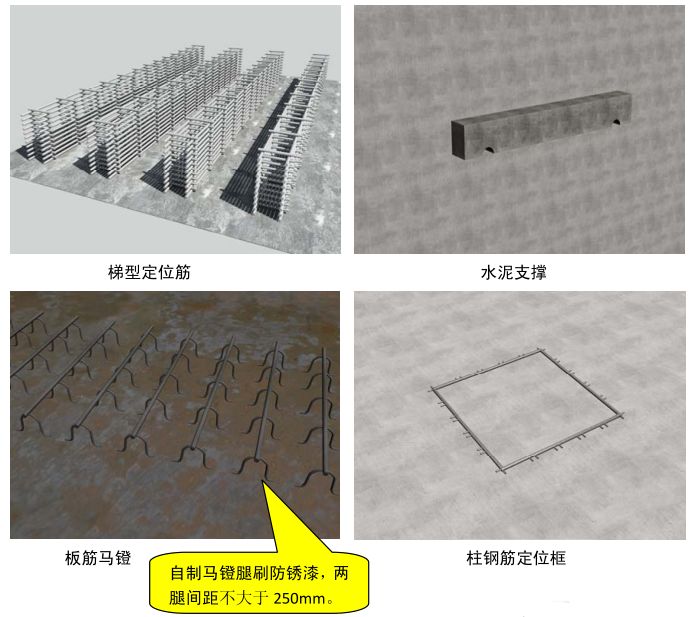

According to the requirements of drawings and specifications, draw processing drawings of trapezoidal positioning reinforcement, column reinforcement positioning frame, stirrup, cement support, etc., and process and manufacture or purchase finished products after being reviewed by the technical director.

key points of operation 1.

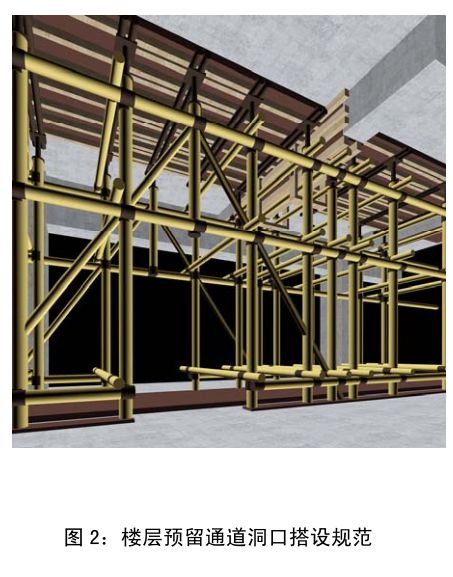

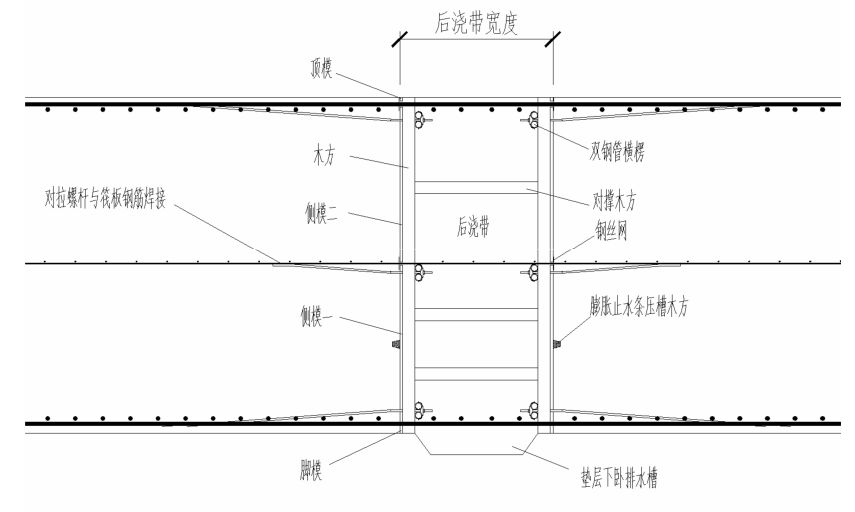

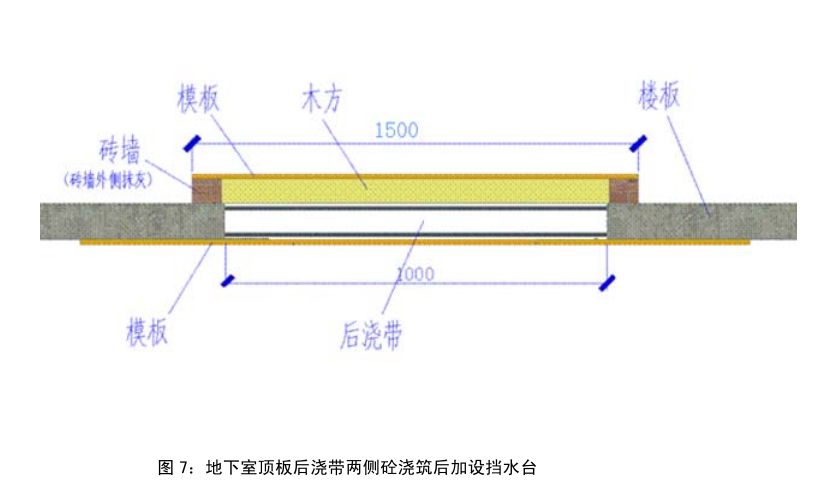

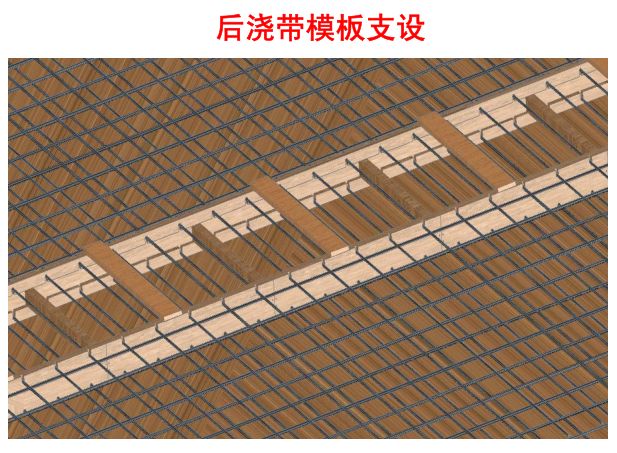

The post cast strip concrete shall not be removed before pouring; The floor passage shall reserve the frame opening according to the clear position in the scheme, and the post cast strip surface shall be protected and strictly implemented in the implementation process.

The thread heads that pass the self inspection shall be randomly sampled and inspected by the quality inspector.

4.

5.

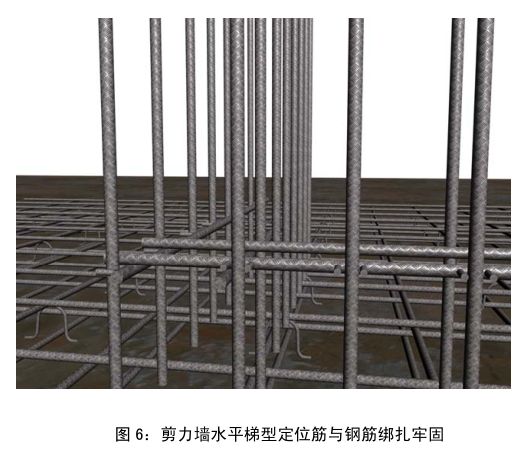

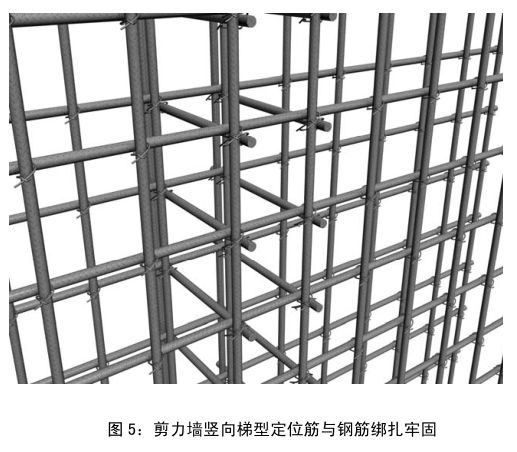

Shear wall reinforcement positioning 4.

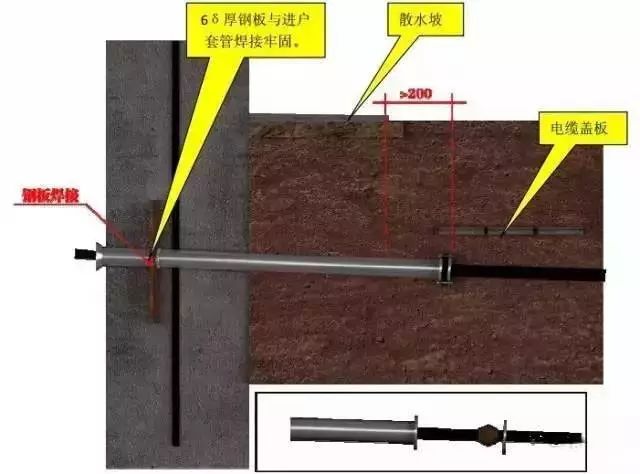

A water retaining platform shall be added after the concrete pouring on both sides of the post pouring belt of the basement roof, and the post pouring belt of the outer wall of the basement shall be implemented according to the design scheme.

When processing rebar threads, water-soluble cutting lubricant shall be used; Do not use engine oil, lubricating fluid or no lubricating fluid for threading.

key points of operation 1.

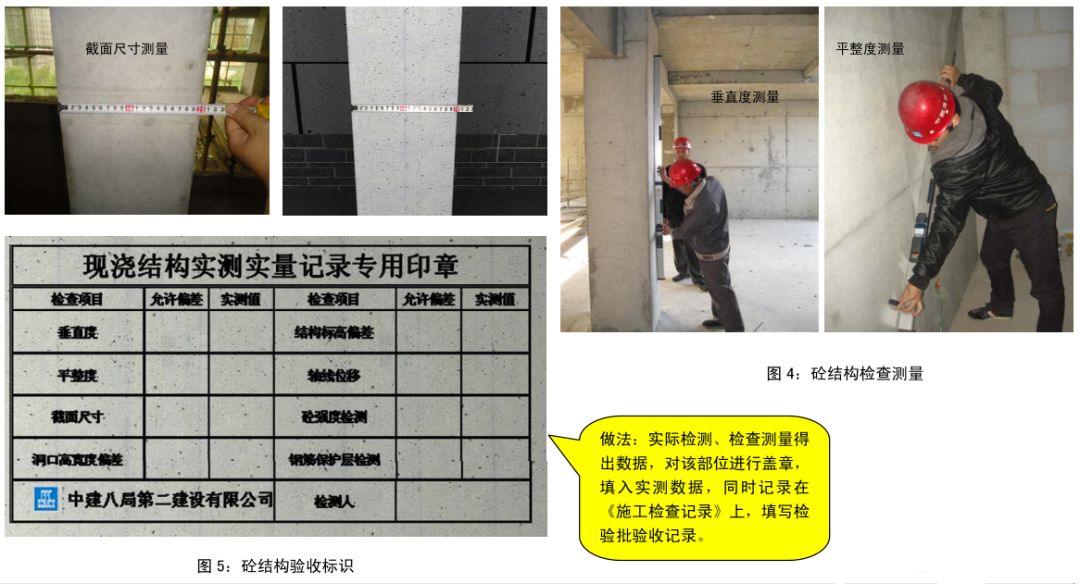

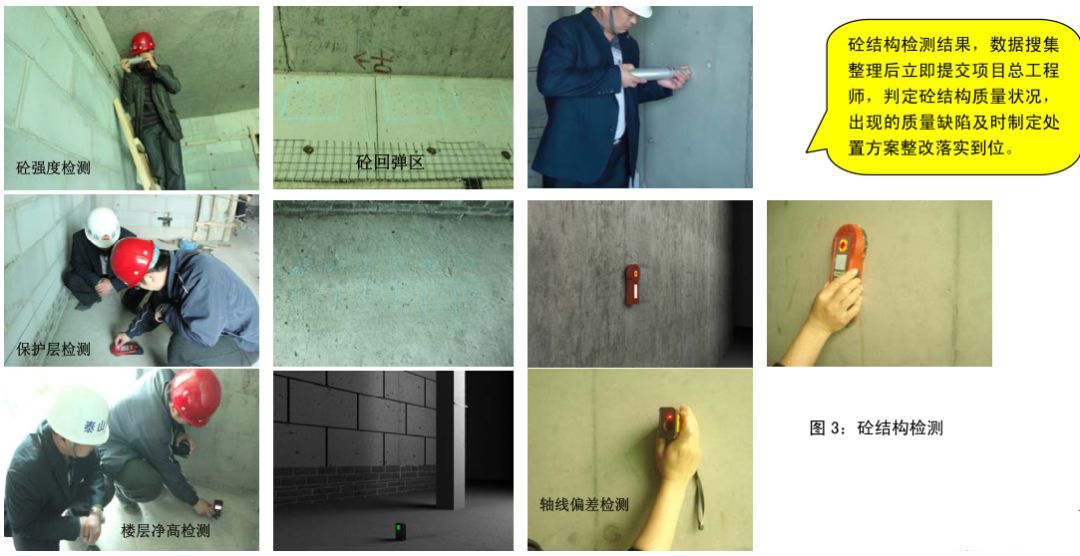

Inspection and testing tools meet the requirements, and personnel work with certificates or have testing ability..

4.

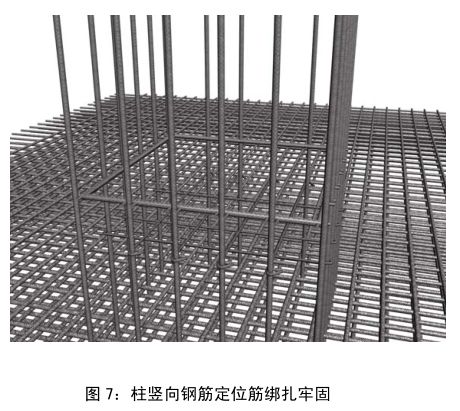

A reinforcement positioning frame is added 5cm and 50cm higher than the top surface of the floor.

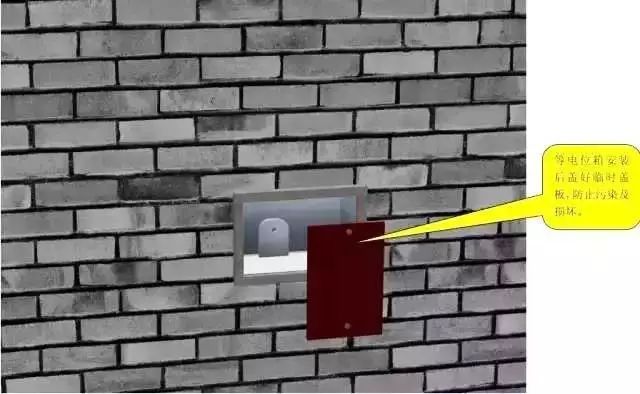

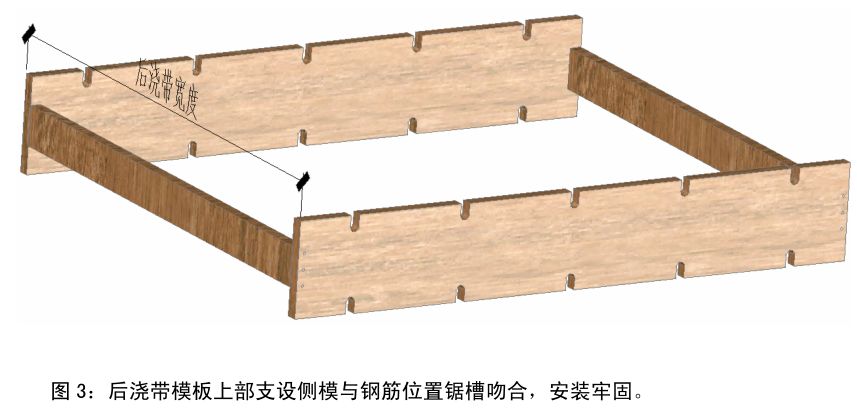

Wooden squares shall be added on both sides of the upper opening, which shall be sealed and protected with wooden formwork until it is opened during concrete pouring.

2.

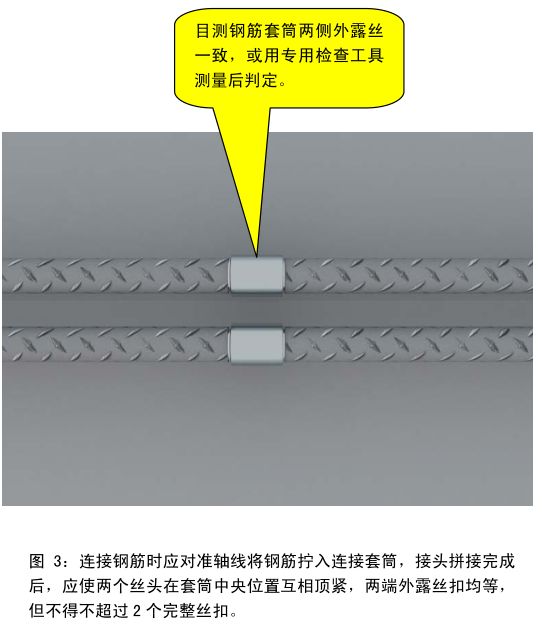

After the joint is spliced, the two screw heads shall be pressed against each other in the center of the sleeve, and the exposed screw threads at both ends shall not exceed 2 complete screw threads.

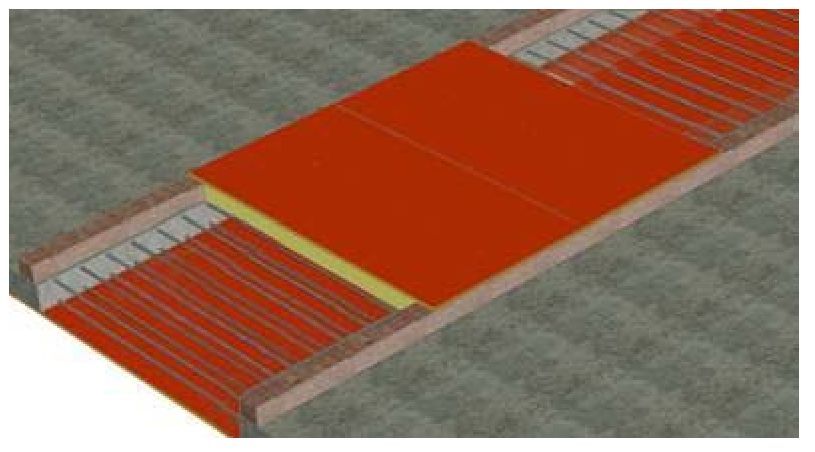

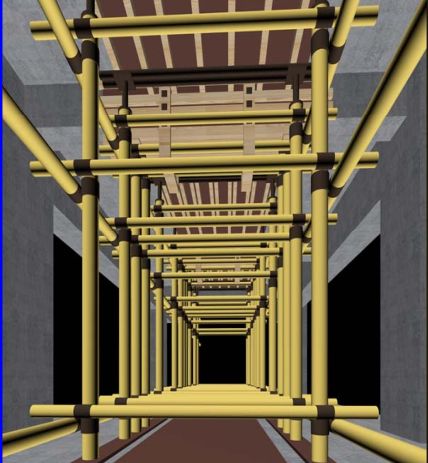

The post cast strip formwork erection must adopt an independent design system, which will not affect the installation and dismantling of the full hall scaffold, and the upper and lower vertical poles are placed on the same axis.

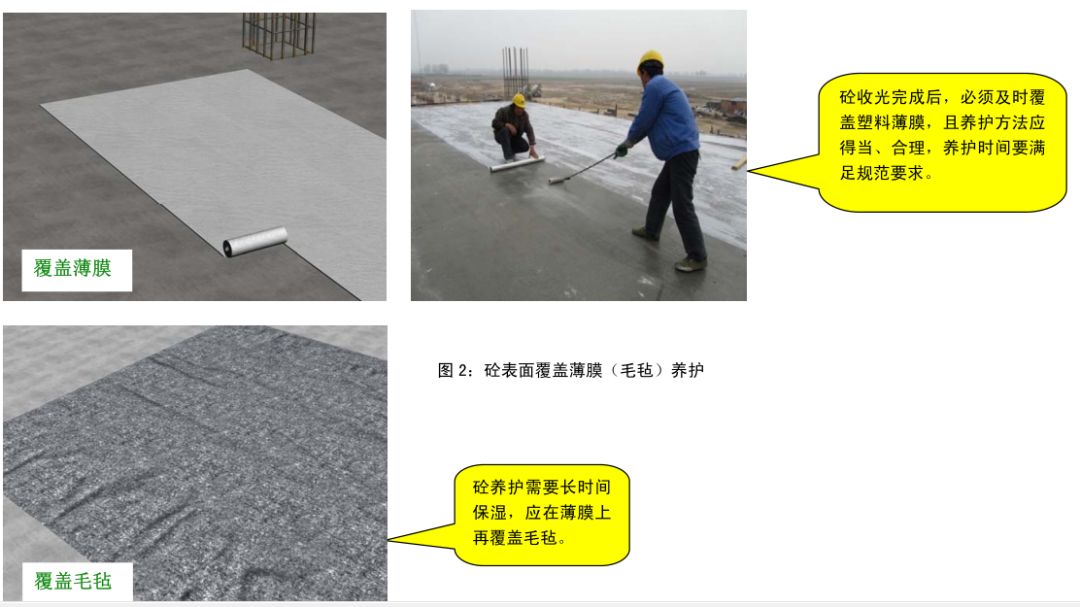

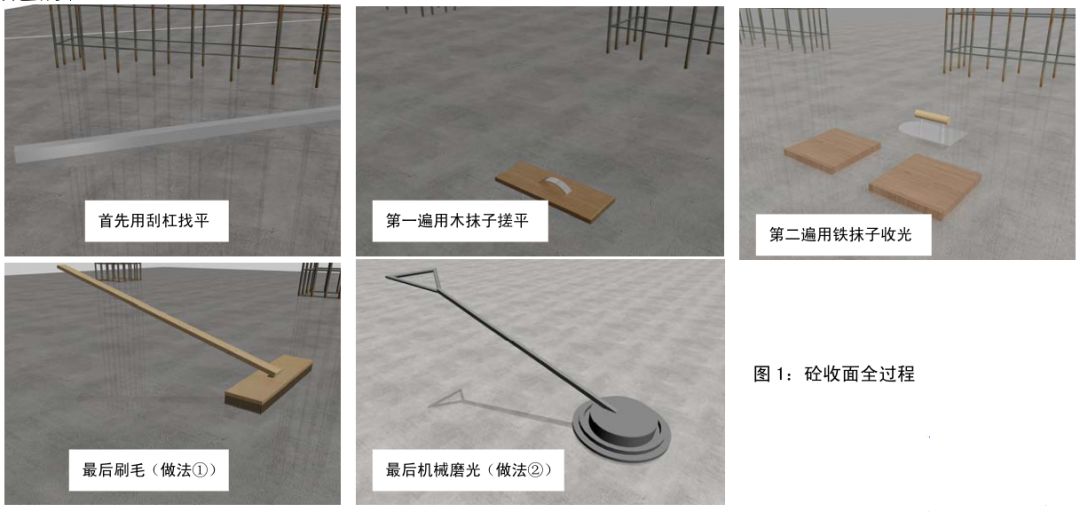

The time and connection of two or three times of concrete surface finishing shall be controlled in place.

In order to prevent missing screwing of joints, after each joint is tightened, it must be marked with red paint on the joint, and unqualified ones shall be marked with white for inspection.

The supervision and control of concrete vibration shall be in place (the vibrator controls the moving distance of the vibration point to be no more than 1.5 times, the action radius of the vibrator < about 90cm = "" >, the vibrator enters 5cm into the lower layer, inserts and pulls out slowly, and the shift handover procedures of the vibrator shall be completed to avoid missing vibration).

key points of operation 1.

3.

5.

3.

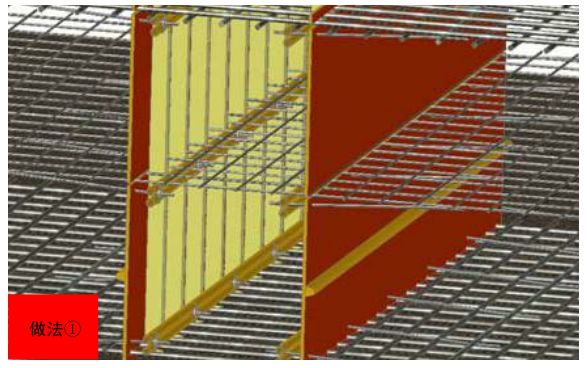

The key to the binding of frame column reinforcement is to control the vertical and relative position of longitudinal main reinforcement.

Structural column reinforcement reservation I.

When the qualified rate is less than 95%, the sampling inspection shall be doubled.

6.

The spacing of vertical trapezoidal reinforcement shall not be greater than 2m, and there shall be no less than 2 in each section of wall.

7.

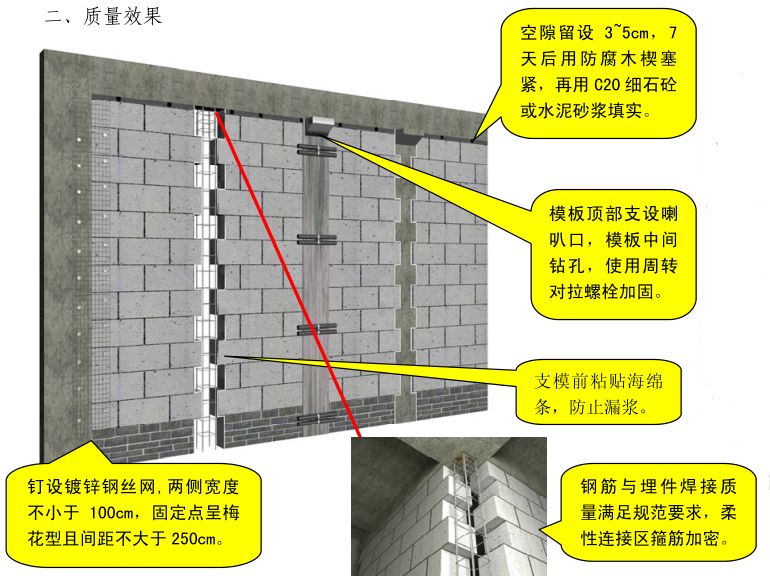

2、 Quality effect 7 quality control of concrete pouring process I.

When the qualified rate is still less than 95%, all thread heads shall be inspected one by one.

3.

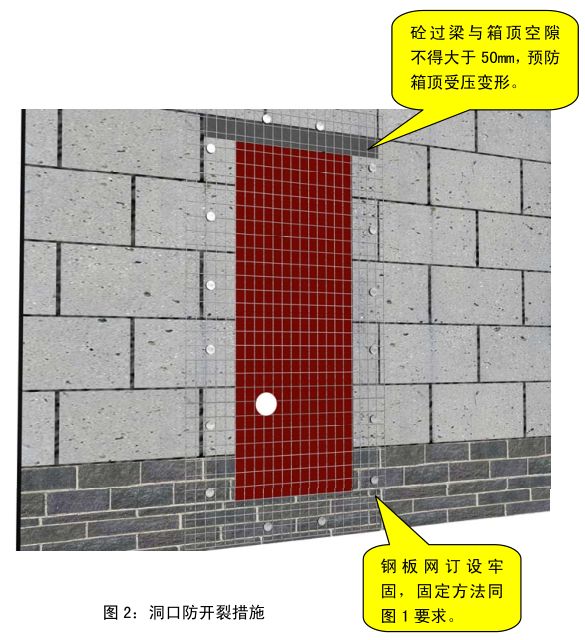

2、 Quality effect 3.

2、 Quality effect 6 post cast strip formwork erection I.

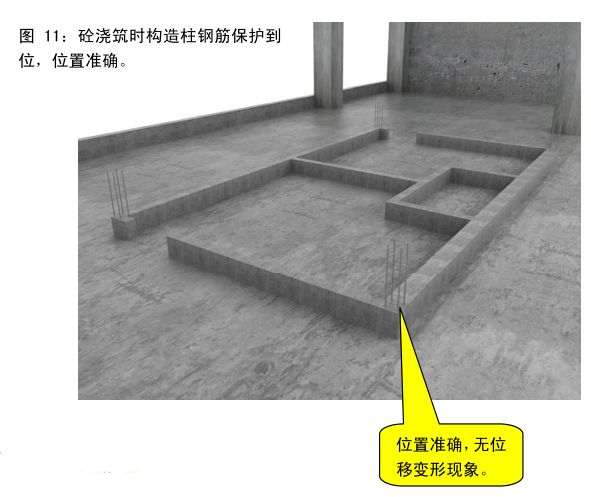

Protective measures for structural column reinforcement are in place.

2.

4.

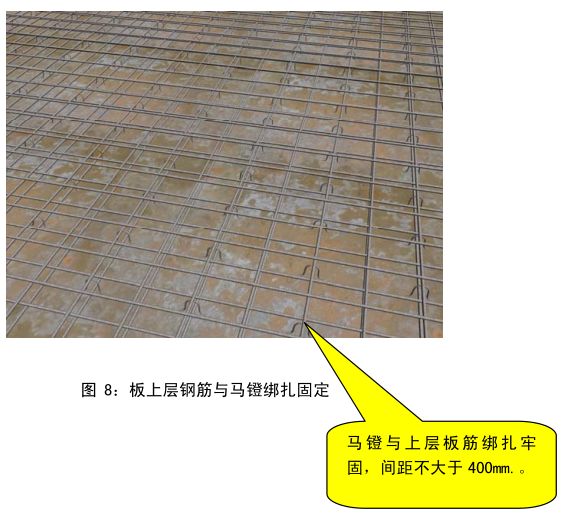

Stirrups shall be placed after the bottom reinforcement of cast-in-situ slab is laid, and the spacing shall not be greater than 500mm, which shall be firmly bound with the upper slab reinforcement.

The effective thread length of the screw head of the standard joint shall not be less than 1 / 2 of the length of the connecting sleeve, and the allowable error is + 2p.

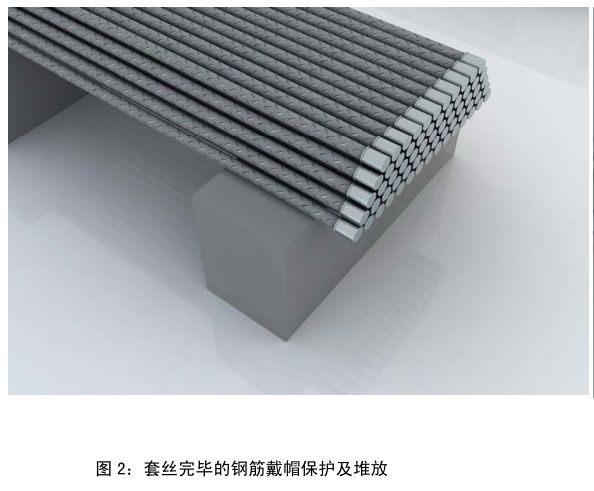

Straight thread connection of reinforcement I.

When connecting the reinforcement, align the axis and screw the reinforcement into the connecting sleeve.

The bottom of the embedded vertical reinforcement of the structural column cannot be directly placed on the formwork to prevent the reinforcement from being exposed.

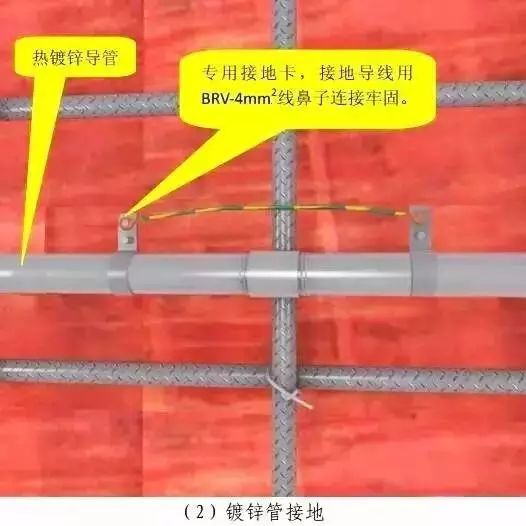

2、 Quality Effect 2 positioning of Wall Column Slab Reinforcement I.

Before the binding of stirrups, the spacing frame is used to limit the position of vertical reinforcement.

2.

6.

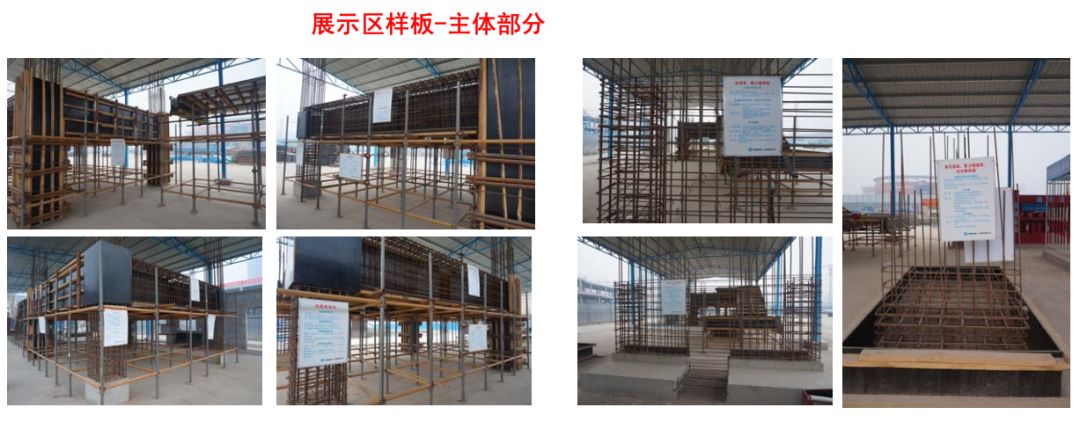

Part I: Civil Engineering 1.

The spacing frame is temporarily fixed between the spacing frame and the scaffold to ensure that the spacing frame is horizontal and corresponding to the column sideline.

key points of operation 1.

Only qualified ones can be used.

It is not allowed to cut with gas cutting.

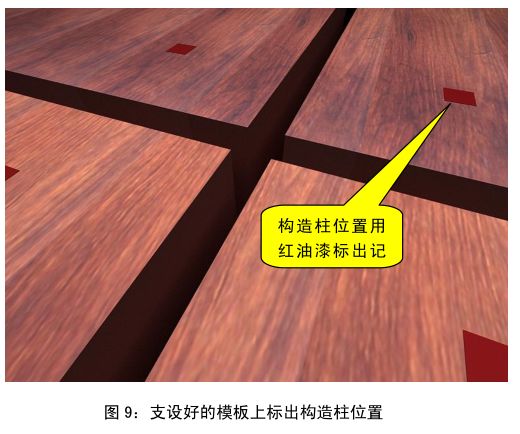

According to the building construction plan, the position of structural column shall be marked with red paint on the erected formwork.

3.

5.

The fabrication of concrete test blocks is standard, and the quantity meets the requirements.

Timely curing and protection after concrete pouring (limit premature loading).

key points of operation 1.

2、 Quality effect 8 fresh concrete pouring and maintenance control 9 quality inspection batch acceptance of cast-in-situ structure i.

The diameter and length of the processed steel wire head shall be checked with thread gauge.

It can be cut with grinding wheel saw or toothless saw on site.

No collision is allowed during concrete pouring.

The end of reinforcement blanking shall be flat without horseshoe shape or deflection.

The thread heads processed by one work shift shall be taken as an acceptance batch, and the random sampling inspection shall be 10%.

Quality control of delivery inspection of commercial concrete, mainly slump inspection.

The ladder bars of wall reinforcement and trapezoidal reinforcement shall be bound and fixed.

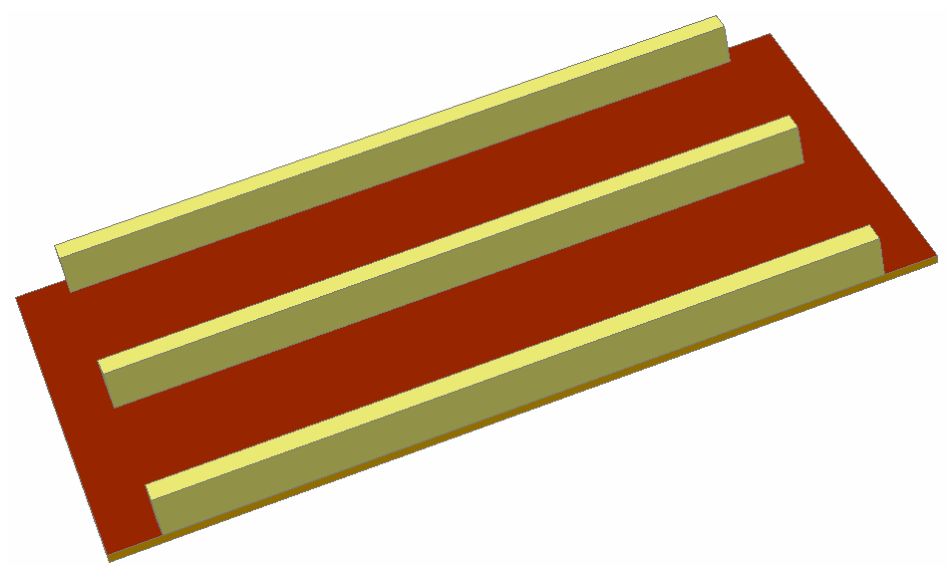

The upper side opening formwork of the post cast strip formwork of the cast-in-situ slab shall be consistent with the saw groove of the reinforcement position, and shall be firmly installed, or it shall be firmly supported with steel wire (plate) mesh.

After the wall reinforcement mesh is bound, cement support and protective layer cushion block can be added.

The concrete shall be transported in time (the front desk feeding personnel and the backstage construction personnel shall keep the information unblocked, and the concrete discharge shall not be too concentrated).

Column Slab Reinforcement positioning 5.

The position of trapezoidal reinforcement should avoid the overlapping length of reinforcement.

Source: in case of infringement, please contact and delete the construction quality standardization Atlas of China Construction Eighth Engineering Bureau.

5.

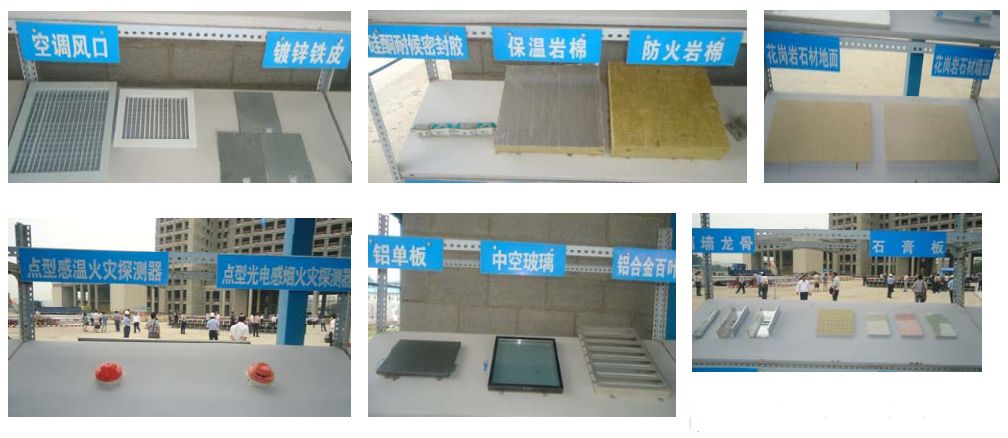

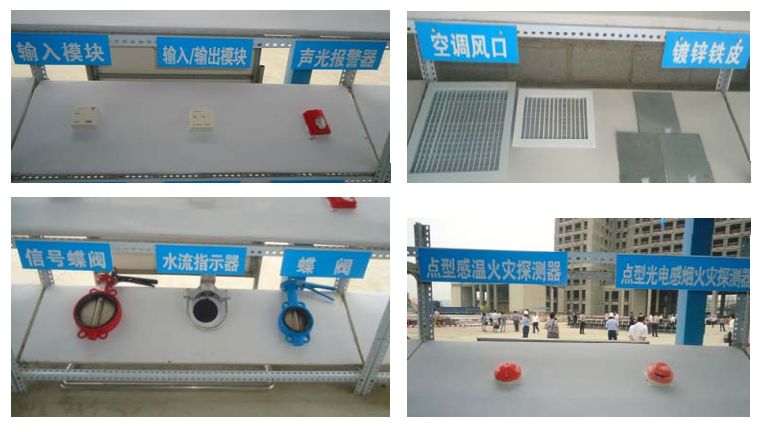

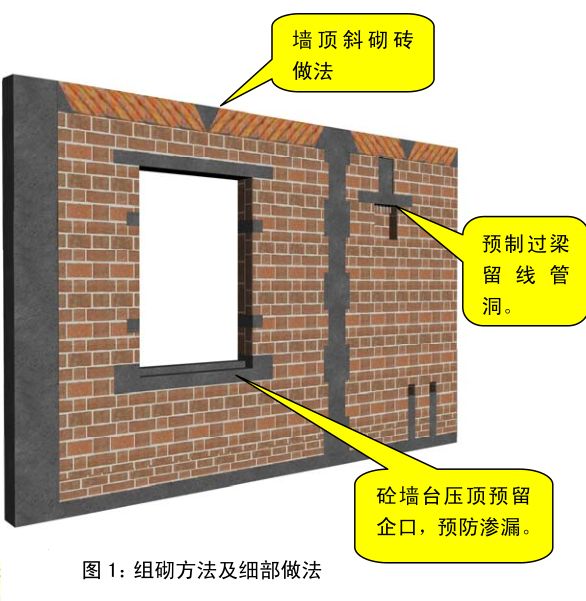

The first part of civil works includes reinforcement works, formwork works, concrete works, masonry works and waterproof works; The second part of the installation includes water supply and drainage and plumbing engineering, building electrical engineering; The third part is the model display, which is rich in three-dimensional practice photos.

And ensure that the screw thread of the reinforcement connecting sleeve is clean and intact.

key points of operation 1.

2.

If necessary, processing measures shall be taken, and at least 2 stirrups shall be set at the top to prevent the deformation of joint bar.

2.

Before binding reinforcement, the vertical reinforcement shall be straightened and corrected in place.

4.

The qualified wire head shall be protected with protective cap.

The specification of reinforcement shall be consistent with that of the connecting sleeve, and the type, pitch and external diameter of reinforcement thread shall be matched with that of the connecting sleeve.

Fabrication of bending anchor of structural column reserved reinforcement meets the requirements of drawings and specifications; The welding quality of the embedded steel plate (and reinforcement) connected to the top of the structural column is guaranteed.

It shall be arranged in quincunx shape (or horizontal ladder reinforcement shall be set, the spacing shall not be greater than 2m, and each section of wall shall not be less than 2); The cushion block of the protective layer shall be evenly fixed on the reinforcement mesh, and the spacing shall not exceed 100cm.