This method is applicable to dry base.

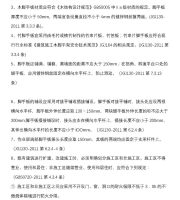

Lap in the short side direction: ① lap of coiled material: remove the isolation film on the lower surface of polymer double-sided self-adhesive tape (hereinafter referred to as “tape”) and paste it on the lap lower coiled material.

② Coil butt joint: the bonding material of butt joint coil is coil (without particle anti sticking layer).

③ The excellent puncture resistance enables it to bind the reinforcement directly after paving.

1、 Product introduction polymer self-adhesive film waterproof coiled material is a new type of water-proof coiled material composed of polymer compound main material, self-adhesive film layer, anti adhesion and anti adhesion material layer (except overlapping edge area) and isolation material layer (when required), which is bonded with post cast concrete to prevent water channeling on the bonding surface.

When the basement floor coiled material waterproof layer is laid by the empty laying method, it can be constructed on the wet base course, but the base course shall be solid and free of open water.

Remove the isolation film on the upper surface of the tape after rolling, and paste the lap upper coiled material on the tape.

After removing the surface isolation film, paste the upper butt joint coil and roll it to make it firmly bonded.

3、 Construction process part I: base course treatment waterproof coiled material base course treatment: the base course shall be cleaned at the internal and external corners, post cast strip, high and low spans, sump pit, foundation pit and other node details, and the surface shall be free of looseness, burr, sand and other phenomena.

Use broom, shovel and other tools to clean the surface protrusions, and then the construction can be carried out.

Part IV: local repair detail nodes (mainly three-dimensional corners and positions with large stress after coil splicing) are sealed with adhesive tape.

Joint sealing treatment: the detailed joints of coil splicing (mainly the three-dimensional angle and the position with large stress after coil splicing) are sealed with adhesive tape.

Part II: additional layer setting part III: waterproof coiled material lapping (key) long side coiled material lapping: directly lap and roll after removing the isolation film on the lap side of coiled material.

2、 Performance characteristics ① single layer paving can achieve first-class waterproof effect.

⑤ It forms a permanent organic combination with the concrete, is not affected by the displacement of the base layer, and can maintain high peel strength in the long-term immersion environment.

* statement: part of the content of this picture and text comes from the Internet, and the copyright belongs to the original author.

Prepared by: Wang Zhe Yang Baomin proofread by: Peng Liyun US editor: Wang Zhe Yang Baomin..

If the copyright is involved, please contact to delete the text.

④ It has strong heat insulation, water resistance, compression resistance and moisture resistance.

The sundries, dust and ash of the base course shall be cleaned, and the base course shall be accepted.

Cut the coil into a strip and place the adhesive surface upward.

When the polymer self-adhesive film waterproof coiled material has large penetrating damage, the sand particles on the upper surface of the damaged part shall be removed with a hot-air shovel (the range shall not be less than 70mm in all directions beyond the damaged range), then the adhesive tape shall be pasted, and then a piece of coiled material shall be used as a “patch”; Other situations can be repaired directly with adhesive tape as appropriate; If only small pieces of glue and sand are missing in the coil, it is not necessary to repair.

② Convenient construction, no protective layer, environmental protection and no pollution.

Roll it to make it bond firmly.

This method is applicable to the situation that the waterproof layer may be soaked in rain, which can avoid separation.

If necessary, heat the tape properly, and the bonding effect is more ideal.