The shield machine is known as the “king of machinery” and is the most complex of all kinds of construction machinery.

This railway needs to cross the Pearl River Estuary.

Therefore, there are high requirements for the performance and handling of the TBM.

The total length of the subsea tunnel is 13.69km.

The picture shows the subsea tunnel.

The construction of this tunnel can be regarded as a “test ground” for deep-sea tunnel construction, from which various experiences and deficiencies can be learned in time.

Usually, the shield machine is composed of tens of thousands of parts.

The picture shows the shield machine Pearl River Estuary subsea tunnel, which is the deepest subsea tunnel built by China so far.

Although China is already a powerful shield machine country, and the technical performance of many shield machines developed in China has reached the international advanced level, so far there is no shield machine on the market that has participated in the construction in such a harsh environment.

With the spirit of pioneering and enterprising, Chinese engineers began the construction of this tunnel, offering China’s 3900 ton heavy equipment, Dawan area code shield machine, to challenge the deepest subsea tunnel, Dawan area code shield machine, which was jointly developed by China Railway Tunnel Bureau and China railway equipment, The shield machine is specially designed for the construction of Shenzhen Jiangmen tunnel with the highest water pressure.

Therefore, the state has specially developed the super large-diameter slurry balance shield machine in Dawan district.

The cost of a shield machine is expensive and needs tens of millions of yuan.

Domestic engineers believe that the construction of this tunnel, It will enable China to accumulate valuable construction experience in the construction of extra long subsea tunnels and ultra-high pressure waters.

Therefore, subsea tunnel excavation engineering is full of challenges and risks.

The team will not only face complex subsea geological environment, but also deal with strong underwater pressure.

At that time, the industrial powers monopolized technology, The way of selling only equipment but not technology is asking exorbitant prices.

At the same time, it can further test the performance level of domestic shield machines through this harsh environment.

For complex geology and long-distance underwater tunnel excavation, the shield machine has also made various technical improvements to strengthen its performance.

Therefore, driving a tunnel 100 meters under the sea is a blank in the field of infrastructure.

The maximum underwater depth is 115m.

The subsea tunnel needs to pass through 6 secondary fault zones and 3 groups of fault fracture zones along the way.

It is equipped with an ultra-high pressure automatic compensation system, which can realize automatic pressurization during construction in a 12bar ultra-high pressure environment.

Once the tunnel is completed, it will further advertise the performance of domestic shield machines and attract foreign customers, So as to improve the competitiveness of domestic shield machine in the international market…

The picture shows the subsea tunnel.

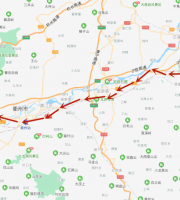

The picture shows the shield machine Shenjiang railway with a total length of 116km.

The rock mass is uneven in soft and hard.

Nowadays, the rise of domestic shield machines has broken the pricing power of these countries in the field of shield machines, forcing these countries to reduce prices.

Although China has learned from the construction experience of the subsea tunnel from the Shenzhen China subsea tunnel and the Hong Kong Zhuhai Macao subsea tunnel projects, However, this tunnel with a maximum water depth of more than 100 meters was built for the first time, which also broke the construction depth of subsea tunnels all over the world.

The diameter of this shield machine reaches 13.32m, With a total length of 133 meters and a weight of 3900 tons, the cutter head of the shield machine has been specially strengthened.

New breakthroughs will have new challenges.

The shield machine is prone to problems in the fracture zone.

It is a railway line passing through Shenzhen, Guangzhou, Dongguan, Zhongshan and Jiangmen.

The shield machine is equipped with a small knife spacing atmospheric pressure composite cutter head, which provides the cutting capacity in geological faults, so that the tunneling capacity can be improved.

In addition, it is also equipped with a four circuit pressure maintaining system, which can further realize accurate and rapid control, The shield machine is reserved with an air cushion direct discharge system, which can quickly discharge the earth and gravel excavated, so as to improve the excavation speed.

How difficult is it to construct 115m underwater? The maximum water pressure here reached 1.06 MPa, equivalent to 10 Standard atmospheres.

20 years ago, the shield machine was still a “money printer” in Europe, America and Japan.