Surface vibrator surface vibrator is also called “plate vibrator”, which is mainly used for pouring large area, small thickness and flat working surface, such as ground, floor and roof.

Generally, the vibration time of each point shall be 20-30s.

① Internal vibrator ② surface vibrator ③ external vibrator ④ vibration table in the construction site, external vibrator and vibration table are rarely used.

The “vibrator” is divided into eccentric type and planetary type: the former uses the rotating shaft with eccentric mass installed in the center of the vibrator, and the centrifugal force generated during high-speed rotation is transmitted to the vibrating shell through the bearing, so as to make the vibrator produce circumferential vibration; The latter uses the rotating shaft suspended at one end of the vibrating rod.

The concrete vibrator is the machine for mechanized concrete tamping.

One of the important reasons is that the operators on the construction site lack the necessary basic knowledge.

When it rotates, the conical part at the sagging end rolls along the conical surface in the rod shell, so as to form the planetary motion of the rolling body to drive the rod body to produce circumferential vibration.

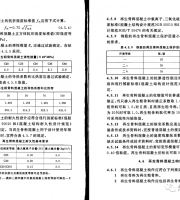

Examples of honeycomb and pitted surface caused by incomplete vibration ▼ quality problems often occur due to poor vibration.

This paper only introduces the construction operation process in detail for the two kinds of vibration equipment commonly used on the construction site: internal vibrator and surface vibrator.

When using high-frequency vibrator, the minimum time shall not be less than 10s, but the concrete surface shall be level, there shall be no significant subsidence, no bubbles and mortar on the surface· The insertion points of vibrating rods shall be evenly arranged and can be moved in the order of determinant and staggered.

It is too short to be tamped.

“Plate vibrator” means that the equipment is directly placed on the concrete surface, and the vibration wave generated by the 2-vibrator is transmitted to the concrete through the 1-vibrating bottom plate fixed with it.

Too long may cause concrete segregation on site.

Therefore, the concrete vibration equipment and operation technology are interpreted for reference and learning to improve the concrete construction quality! ▼ during concrete pouring, air bubbles must be removed and tamped to make the concrete tightly combined and eliminate the honeycomb and pitted surface of the concrete, so as to improve its strength and ensure the quality of concrete components.

There are four main types of concrete vibrators: internal vibrator, surface vibrator, external vibrator and shaking table.

At the same time, when vibrating the upper layer of concrete, it shall be carried out before the initial setting of the lower layer of concrete· The vibration time of each insertion point shall be well controlled.

If the concrete vibration operation is not well done, the concrete structure will have loose surface, defects, exposed reinforcement or cracks due to uneven vibration, missing vibration and other reasons.

1.

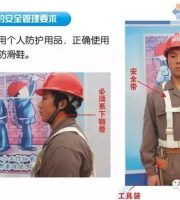

They shall not be mixed to avoid confusion and missing vibration· When the vibrator is used, the distance between the vibrator and the formwork shall not be greater than 0.7 times of the action radius of the vibrator, and shall not vibrate close to the formwork, and collision with reinforcement, pipeline, lifting ring, embedded parts, etc.

The vibrator is suitable for mass concrete, foundation, column, beam, wall, plate with large thickness, prefabricated components, etc.

When vibrating the upper layer, it shall be inserted into the lower layer for 5-10cm to eliminate the joint between the two layers.

shall be avoided as far as possible.

If the concrete is not dense, it will weaken the section of the member and reduce the bearing capacity of the concrete member; In addition, fine holes and cracks make it easy for external water and gas to invade and corrode the reinforcement, resulting in premature damage of the structure.

2.

Interpretation of “plate vibrator” vibration operation process ▼ [guide] key points of operation process: · the surface vibrator shall vibrate continuously for a certain time at each position.

The front and rear positions and the overlap between rows shall be 3-5cm to prevent vibration leakage· The action thickness of surface vibrator is limited.

Generally speaking, the effective thickness of unreinforced or single reinforced plate is 20cm, and that of double reinforced plate is about 12cm· For large-area concrete ground, two vibrators can be used to move upward in the same direction to ensure concrete compaction…

Special attention shall be paid to plastic concrete.

Interpretation of “vibrator” vibration operation process ▼ [guide] key points of operation process: · vibration methods include vertical vibration (the vibrator is perpendicular to the concrete surface) and oblique vibration (the vibrator is at a certain angle to the concrete surface)· During the operation of vibrating rod, it is necessary to “insert quickly and pull out slowly”· For hard concrete, sometimes it is necessary to reinsert the vibrator near the extracted hole to fill the hole· In the process of vibration, the vibrating rod should be slightly pumped up and down, and the upper and lower vibration should be uniform· When the concrete is poured in layers, the thickness of each layer of concrete shall not exceed 1.25 times the length of the vibrator.

Internal vibrator internal vibrator, also known as “vibrator”, can be inserted into the interior of concrete pouring for vibration, making it the most common tool for concrete pouring and vibration.

Generally, the continuous vibration time is 25-40s, but the slurry on the concrete surface shall prevail· When moving, it shall move forward in rows according to this vibration.