If it is really necessary to use an alternative diluent, be sure to do a small-area trial coating first, and then apply a large-area coating after determining that the bottom is no longer bitten.

During construction, try to use the supporting diluent provided by the coating manufacturer instead of alternative diluent, so as to avoid the problem of biting the primer due to the use of strong diluent for the finish paint.

If the primer is not matched with the topcoat, the primer film is easy to swell by the strong solvent in the topcoat.

2.

The surface coating is too thick at one time, a large number of strong solvents remain in the paint film and cannot volatilize in time, which prolongs the drying time of the paint film.

If phenolic paint is used for primer and nitro paint is used for finish, the solvent in nitro paint will bite up the oily phenolic paint and separate it from its attached base.

Therefore, when painting anticorrosive paint, the added diluent shall not exceed 5% of the total paint amount, and it shall be noted that weak polar diluent shall not be used at the bottom layer, while strong polar solvents such as acetone, esters and high boiling aromatic solvents shall be used for the upper layer.

5.

When the problem is not serious or only occurs in a small area, the finish paint can be recoated to cover it; If the wrinkle affects the smoothness, the finish paint can be covered again after grinding and leveling; For serious “undercut”, all coatings shall be removed and re sprayed…

The oil-based paint film and some synthetic resin paint films modified by dry oil will be eroded once they meet with strong solvents before they are highly oxidized and polymerized.

For example, epoxy floor paint materials are generally produced in a supporting manner.

Once the “bottom biting” phenomenon occurs in the coating supporting system, it will not only make the surface state of the coated object unable to meet the requirements, but also seriously reduce the bonding force between the coating films, and significantly reduce the protective effect of the whole coating.

The front and rear coatings are not matched.

Treatment: in case of “bottom biting”, corresponding treatment shall be carried out according to the severity.

The solvent resistance of the primer film is poor, or the topcoat contains strong solvent that can swell the primer, which will also bite the bottom.

Therefore, for two-component or multi-component coatings, the components must be mixed according to the formula proportion to ensure the complete curing of the film.

If materials from different manufacturers need to be used, they can be tested in a small area to ensure that there is no undercut, and then used in a large area to avoid losses.

Therefore, the coating thickness of each paint film shall be carried out in strict accordance with the design requirements to avoid the problem of excessive coating thickness.

6.

Cause analysis and solutions: 1.

If the top coat is too thick and the drying time is too long, the bottom biting phenomenon will also occur.

4.

If the primer is not completely dry, the finish paint will penetrate together and affect each other, resulting in undercut.

When the primer is not completely dry, apply the topcoat.

The formulas used by different floor paint material manufacturers are different.

If they are mixed and used, it is easy to cause the problem of floor paint softening.

Lifting: refers to the phenomenon that when coating the upper coating, the solvent in the coating softens and swells the lower coating film, resulting in poor adhesion of the lower coating film, wrinkling, uncovering and even peeling.

3.

The solvent in the topcoat dissolves and softens the primer, causing undercut.

Therefore, it is recommended to select the matching primer and finish for the construction of epoxy floor.

Once the primer softens and expands, undercut may occur.

Therefore, when brushing solvent based coatings, construction personnel are required to be skilled, operate accurately and quickly to prevent repeated brushing.

When brushing the top coat, the operation is not fast, and the repeated brushing times are too many, resulting in undercut.

The amount of curing agent in the formula of the previous coating is not enough, and the film crosslinking is not sufficient.

For example, epoxy floor paint is a kind of film-forming paint, and its toughness and strength can only be reflected when the floor paint is fully cured.

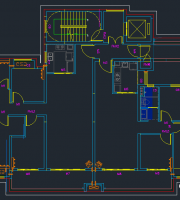

The phenomenon of “bottom biting” will first greatly weaken the adhesion of the lower coating to its bottom base layer, and it is easy to form hollowing or peeling risk in the later process, resulting in shrinkage and wrinkling of the surface layer, showing uneven or irregular lines, as shown in the figure.