(6) Fast construction progress: the required construction period is shorter than other construction methods.

The lapping of triaxial mixing pile and the verticality correction of formed mixing pile are realized by single hole repeated casing drilling of mixing pile, so as to ensure the water curtain effect of mixing pile.

It is now widely used in the retaining structure of open cut tunnel and the water stop curtain of deep foundation pit.

It is a patent owned and developed by Chengxin Industry Co., Ltd., a medium-sized enterprise in Japan.

Equipment composition, classification and performance index 4 Construction sequence of SMW method (1) guide ditch excavation: determine whether there are obstacles and make mud ditch.

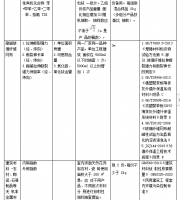

(8) Large excavation depth: the thickness of the wall can be 550 ~ 1300mm, and the common thickness is 600mm; At present, the maximum depth of the wall is 65m, which can be constructed to a deeper depth depending on the geological conditions; It is generally used as the retaining structure of foundation pit with a depth of less than 15m.

when crossing the 4th, 6th and 7th silty sand layers, it shall be stirred to the design depth at a speed of no more than 0.8m/min, and then re stirred after static shotcreting for 20 seconds.

There shall be no more than 2 welded joints in a single section steel, and the welded joints shall not be located at the supporting position or near the excavation surface, etc; The vertical positions of adjacent section steel joints shall be staggered, and the staggered distance shall not be less than 1.0m..

The construction method was published in Japan in 1976.

(3) Strong reliability: insert H-shaped steel or steel plate, with certain composite structure strength.

(4) Strong water retaining performance: the drill pipe has the characteristics of alternating spiral propulsion wing and mixing wing.

At the same time, the cement fortifier is sprayed at the bit and mixed repeatedly with the foundation soil.

(2) Place the guide rail.

The average speed of shotcreting and tripping down of triaxial mixing pile shall be controlled at 1m / min.

Preface SMW is the abbreviation of soilmixingwall.

If only impermeability is required, the process of inserting H-section steel or steel plate can be cancelled, so as to reduce investment and speed up the construction progress.

(7) SMW after construction.

2.

Compared with the commonly used construction methods such as diaphragm wall and bored pile, it mainly has the following characteristics: (1) little interference to residents: there is basically no noise during construction.

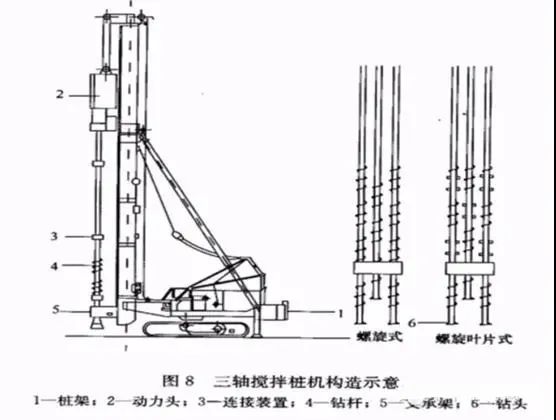

The most commonly used SMW construction method is the triaxial drilling mixer, in which the drill pipe can be used for cohesive soil and gravel soil and bedrock.

Due to different equipment, The pile strength and uniformity of the new three-axis drill are obviously better than those of the traditional two axis drill.

(3) Set construction signs.

When the section steel is welded and extended, the groove equal strength welding shall be adopted, and the weld quality grade shall not be lower than grade II.

Main characteristics and scope of application of the construction method the traditional deep mixing pile construction method adopts the traditional biaxial mixing drilling rig.

With the repeated drilling and mixing, the cement fortifier and soil can be fully mixed, and the wall has no joints in the whole length, so it can have more reliable water stop than the traditional continuous wall, and its permeability coefficient K can reach 10-7cm / s.

In this construction method, the multi axis drilling mixer is used to drill to a certain depth on the site.

(7) multi purpose (applicable to various strata): it can be used in cohesive soil, silt, sand, gravel soil Φ Pebbles above 100 and rock layers with uniaxial compressive strength below 60MPa shall be used.

(5) Low cost: this enclosure construction method can generally recover H-section steel and other bending materials through certain construction measures to reduce the construction cost, and the outward transportation volume of waste soil is much less than that of other construction methods; The price of general machine shift is about 7000 yuan, and the comprehensive unit price analyzed according to 25% cement content is generally about 220 yuan / m.

5.

In addition, some other models have been developed for construction under urban viaduct, where space is limited, or submarine wall construction, or soft foundation reinforcement.

Under general geological conditions, each shift can form a wall of 70 ~ 80m2.

The verticality of the pile, the parallelism between the pile and the pile and the degree of overlapping are very good, which ensures the excellent and reliable waterproof performance, and is also conducive to the insertion and recovery of section steel.

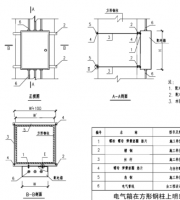

(5) Place stress reinforcement (H-section steel) (6) fix stress reinforcement.

At the same time, the drilling rig fully mixes the cement soil and replaces a large amount of undisturbed soil.

1.

(9) Disadvantages: it has high requirements for the site, leveling the site, bringing its own steel plate, with the cooperation of a small hook machine, and the site width generally needs to be at least about 15m.

During construction, the cement slurry is injected and filled in the original soil gap, while the new triaxial mixing drilling rig adds high-pressure air when filling the cement slurry.

It shall be lifted for 5m at a speed of no more than 1m / min before sinking.

High pressure shotcreting of drill pipes on both sides, air jet of middle drill pipe air compressor, and rotary mixing make the cement content of each cement soil more uniform.

Design requirements (1) hot rolled H-section steel with specification of 488 shall be used as section steel × three hundred × eleven × 18 (HM) 700x300x13x24 on site, the crown beam is exposed 500mm from the upper end of section steel.

(2) Little impact on the surrounding environment: the construction will not disturb the adjacent soil, and will not cause hazards such as adjacent ground subsidence, house inclination, road crack damage and underground facilities displacement.

3.

The three-axis mixing pile is generally constructed by slot hopping double hole full set of re mixing, but under special circumstances (such as corner construction or intermittent construction of mixing pile), it can also be constructed by unilateral extrusion.

(4) SMW drilling and mixing: drilling and mixing, repeated mixing, and mixing during lifting.

After reaching the pile bottom, it shall be stirred and lifted to the pile top at a speed of no more than 1.2m/min.

The overlapping construction is adopted between each construction unit, and then the H-shaped steel or steel plate is inserted as its stress reinforcement before the cement soil mixture hardens until the cement hardens, It forms a continuous and complete underground wall with certain strength and stiffness and no joints; Also known as rigid cement soil mixing pile method, it combines load bearing with anti-seepage and water retaining to make it an enclosure wall of supporting structure with two functions of soil retaining and anti-seepage at the same time.