(3) Subgrade excavation materials shall be used as much as possible, and shall not be arbitrarily discarded except as specified in the drawings or determined as non applicable materials.

After drying for 2-4 hours (controlled according to the temperature), the rotary cultivator shall turn over and mix again; Then, the ploughshare plough is turned deep again from the middle to the side, and the rotary cultivator follows up the crushing and drying in order to reduce the water content as soon as possible.

(4) Before the commencement of filling subgrade, the construction of embankment test section shall be carried out.

Layered hanging line construction: control the thickness of layered hanging line for subgrade filling.

Fine leveling: leveling with grader..

The lime shall be evenly spread with a scraper without blank on the surface.

(6) For the excavation near the residential area, effective measures shall be taken to protect the houses in the residential area and ensure the safety of residents and construction personnel, and provide temporary access roads or bridges for the life and traffic of nearby residents.

Layered plate: layered plate for subgrade filling.

(3) Lime distribution: quicklime shall be mobilized 10d-12d in advance and fully digested.

When loading soil, the quantity of soil loaded per truck shall be basically the same.

Leveling: initial leveling by bulldozer and fine leveling by grader.

When turning over, it shall be turned over by a moldboard plow from both sides to medium depth, and then crushed by a rotary cultivator.

Filling subgrade (1) embankment filling is mainly mechanical operation with manual cooperation.

The size of each grid shall be paved with a cart of filler according to the virtual paving thickness.

(2) The excavation operation shall maintain the stability of the slope and shall not cause damage or worry to various adjacent structures and facilities.

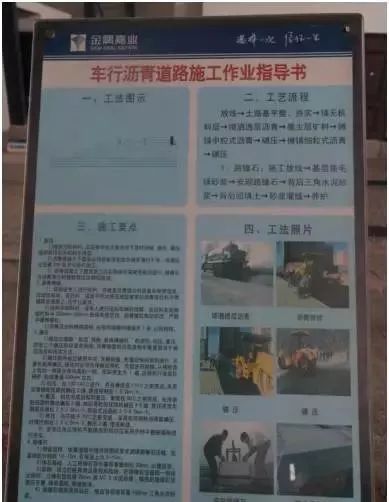

The following is a detailed graphic summary of the standardized management of municipal road subgrade, base course and surface course, which is very worthy of collection! 1、 Subgrade works 1.

Excavated subgrade (1) before the commencement of subgrade excavation, the section diagram of excavation works shall be reported to the supervising engineer for approval, otherwise it shall not be excavated.

(5) The filling subgrade must strictly implement the principle of “scribing the soil, hanging the line for construction and leveling with grader”, so as to ensure that the subgrade surface is flat, the sideline is straight and smooth, the curve is smooth, and the “five degrees” shall be well controlled, that is, compactness, flatness, thickness, width and cross slope.

Manually cooperate and repeat the above steps until the leveling is qualified.

(5) Attention must be paid to the protection of underground pipelines, cables, cultural relics and other structures not shown in the drawings.

2.

(4) Mixing: according to the principle of “balanced speed, overlapping between amplitude, mixing well and mixing thoroughly”, it is better to be high than low at the beginning of paving, and it is better to be missed than supplemented at the end of paving; Two stabilized soil mixers shall be used for centralized mixing, and the mixing depth shall invade the lower bearing layer by 1cm-2cm.

The field test shall be carried out until it can effectively make this kind of filler reach the specified compactness; In principle, the test section is generally not less than 100m; During the test, the type and best combination of compaction equipment shall be recorded; Rolling times, rolling speed and process; The loose paving thickness and moisture content of each layer of material can be used as the basis for the construction control of this kind of filler after the test results are reported to the supervising engineer for approval; At the end of the test, if the test section meets the quality inspection standards, it can be used as a part of the subgrade.

The standardized management of project construction quality must follow the requirements of responsibility commitment, scheme first, model demonstration, pre shift evaluation, process control, quantitative evaluation and continuous improvement, operate in accordance with PDCA cycle, strictly control, continuous improvement, scientific organization and standardized management, and finally realize the overall stability and controllability of municipal road project quality.

Horizontal layered construction: the subgrade filling must be constructed horizontally in layers, and the loose paving thickness shall be controlled according to the soil on the grid.

Once the above structures are found during excavation, they shall be reported immediately, and the operation shall be stopped and the site shall be protected for disposal.

Fixing Socket Waved End Nail Plate

Otherwise, it shall be excavated and retested.

(4) During the whole construction period, the subgrade drainage must always be smooth.

The ash distribution operation can be carried out only when the water content of the soil material is 2-4 percentage points higher than the optimal water content.

During the leveling, pay attention to maintaining the smoothness of the specified road arch, cross slope and joints.

Pay attention to traffic closure during construction.

The lime dosage, mixing depth and uniformity shall be checked according to the specifications, and the maximum particle size of the soil after mixing shall not be greater than 20mm.

In order to ensure the construction quality and improve the construction efficiency, the construction shall be organized according to the operation procedure of “three stages, four sections and eight processes”, namely: three stages: preparation stage → construction stage → acceptance stage; Four sections: filling section → leveling section → rolling section → inspection section; VIII.

Mixing (5) fine leveling: after the mixture is mixed evenly, use the grader for preliminary shaping immediately.

2、 Base Course Engineering 1.

The amount of lime per square meter shall be calculated according to the thickness, predetermined dry bulk density and lime dose, and the paving area of each truck of lime shall be calculated.

Measure the loose paving thickness of lime, and check whether the amount of lime is correct according to the loose density and water content of lime; The local uneven lime quantity shall be treated to ensure the uniform distribution of lime on the working surface.

In the straight section, the grader scrapes from both sides to the middle; Use the roller to quickly roll the initial leveling section immediately to expose the potential unevenness.

Subgrade loading specification: before the laying of each layer of filler, the lime grid on the bottom of the next layer shall be made and the line shall be hung.

Lime stabilized soil base course (1) grid soil: restore the center line and side piles of the subgrade, calculate the stacking distance of each truck of soil according to the tonnage of the truck, and then draw corresponding long and wide grid marks on the lower bearing layer.

(2) Grader leveling, sun turning and crushing: grader leveling, the surface shall be flat, and there shall be a specified road; If the soil material in the borrow area has high water content, it shall be broken and turned over in time after leveling.

Embankment filling width: each side shall be 50cm wider than the design width of the filling layer.

(3) The subgrade filler shall be determined by test and can be used only after it meets the specifications and design requirements.

Source: the network copyright belongs to the original author.

Process: construction preparation → base treatment → layered filling → paving and leveling → watering or drying → mechanical rolling → inspection and visa → subgrade surface renovation; (2) The foundation treatment shall be completed according to relevant regulations and passed the inspection.