According to the design dimensions of ground beam and bearing platform, set out the position of the inner edge line of precast cement slab on the foundation cushion as the control line for the installation of cement slab membrane.

4.

Excavate earthwork according to the design width of foundation, and reserve 30-50cm on the outside of precast cement slab.

6.

The bracing materials can be removed only after the earthwork around the bearing platform is backfilled and stabilized.

It is enough to use the plate membrane and use the tower crane for 1 hour every day, while the use of plate membrane requires frequent hoisting of bricks and cement mortar.

3.

After the strength of the bonding material meets the specified requirements, timbers and formwork shall be used to support the bearing platform, so as to prevent the deviation of the bearing platform caused by the lateral pressure during the earthwork Backfilling on the side of the bearing platform.

The use of prefabricated plate membrane can save a large labor cost.

8.

The prefabricated fetal membrane can be cut and spliced at will on site, with high strength, stiffness, impermeability and frost resistance.

Wet operation method is to mix cement and special glue evenly, then connect the plate with the plate, and add a layer of anti crack belt on the connecting part.

3.

Fine aggregate cement hollow precast slab is adopted for the membrane of precast slab.

Precast cement board is used to replace the traditional foundation brick matrix as the side formwork of bearing platform and ground beam, without masonry and plastering.

It solves the problem of busy material hoisting equipment.

This increases the time for the tower crane to lift other materials~~ Recommended reading ~ ~ to be a drawing joint reviewer, you must have the basic knowledge of drawing joint review, understand the wall calculation methods and precautions, and get a quick start to the project cost! Engineering visa 9 Tips, turn losses into profits! Novice introduction, super detailed pile foundation cushion cap construction process..

7.

The process of using prefabricated plate membrane is simplified.

After the prefabricated plate membrane is installed, earthwork backfilling can be carried out directly after the bonding material has a certain strength.

Installation of prefabricated tire formwork: during installation, the tower crane shall be used to lift and cooperate with manual handling to the designated position.

Comprehensive benefits 1.

2.

Construction method features 1.

In order to prevent the sinking and displacement of the side formwork of the bearing platform, a 40x50mm square timber shall be padded under the side formwork of the bearing platform every 500mm.

The prefabricated cement board replaces the traditional foundation brick matrix technology, which is suitable for the side formwork of foundation beams, bearing platforms, water collecting wells, large rafts and other foundation parts, reducing cost and increasing efficiency, saving trouble, labor and money! This paper takes the engineers of Hunan No.

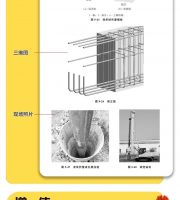

Process flow measurement and setting out → foundation earthwork excavation → pouring concrete cushion → setting out and positioning of precast membrane → hoisting precast slab → trial sample placement → installation of precast slab membrane → reinforcement → earthwork backfilling → pouring cushion operation points 1.

The height of bearing platform is less than 600mm, and the side formwork of bearing platform is fabricated at one time; If the height of bearing platform is > 600mm, the side formwork of upper and lower bearing platform shall be assembled; For the two-layer superimposed side formwork of bearing platform, after the first bearing platform side formwork is in place, the next layer of bearing platform side formwork shall be assembled, the upper and lower layers shall be connected with cement glue, and a layer of anti crack belt (grid cloth) shall be added on both sides, with the non cutting surface facing upward to ensure the flatness of the upper opening.

If the traditional brick membrane needs 15 or more people to build continuously, the plate membrane only needs about 5 workers to install continuously, which can save about half of the construction period compared with the traditional brick membrane.

The size of cement precast slab is 90mm / 120mm / 200mm (thickness) x600mm (width) x2800mm (length).

2.

2.

After it is in place, the external earthwork shall be backfilled and compacted immediately.

5.

The dry operation method adopts reinforced concrete casing connection, angle connector, or U-shaped connector, etc.

For the pouring of cushion concrete, the pouring width of cushion shall fully consider the external expansion of precast tire formwork, protective layer, waterproof layer and precast tire formwork by 100mm.

6 Engineering Co., Ltd.

as an example to learn this new process.

Considering the integrity of the precast slab mold, during the site construction, the height of the precast slab mold of the bearing platform shall be installed in place according to the design drawings, and then the bottom slab concrete cushion shall be poured.

After the completion of traditional brick membrane brick masonry, plastering is required.

The top surface of the timber shall not exceed the elevation of the foundation concrete cushion layer.

There are two assembly methods: wet operation method and dry operation method.