The masonry wall shall be plastered to the base level until the shear wall is flush, and then thin plastering (when mechanical spraying plastering is adopted, the masonry wall and shear wall shall be sprayed and formed at one time).

Quality acceptance standard for Building Decoration Engineering gb50210-2018; 4.

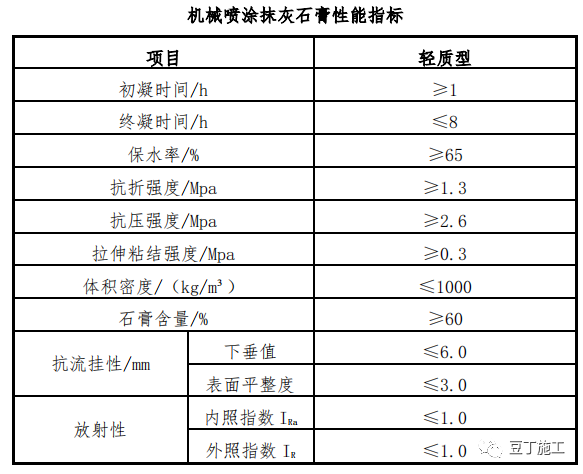

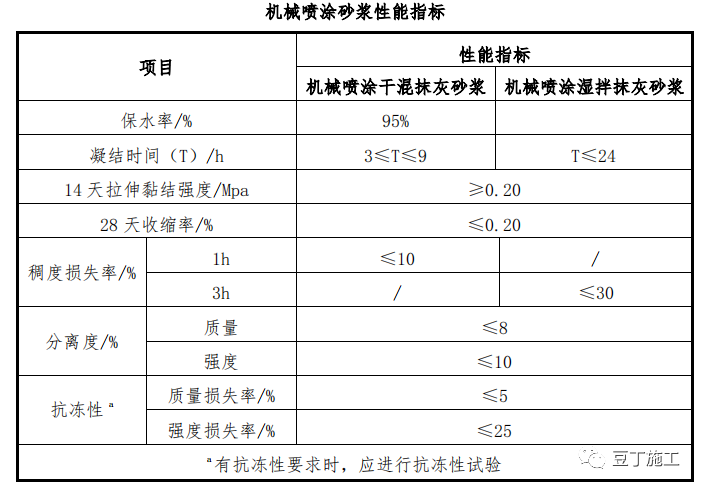

(2) When adopting mechanical spraying process, in addition to meeting the relevant provisions of light plastering mortar, it must also meet the requirements of mechanical spraying mortar (JC / t2476-2018).

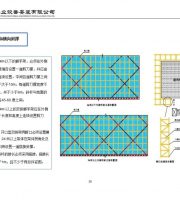

When high-precision formwork process + ordinary masonry is adopted, the masonry wall needs to be scaled down.

The thin plastering of the wall generally adopts the bottom layer or light bottom layer plastering gypsum.

Requirements for the scale of masonry wall: (1) high precision formwork process + ordinary masonry: the scale of each side of masonry is 5mm ~ 10mm (determined according to the brick thickness); (2) high precision formwork process + strip / high-precision masonry: strip and masonry are not scaled.

scope of application 1.

3) the exposed reinforcement head of the base course shall be removed and polished, and the exposed reinforcement and binding wire shall be subject to rust prevention treatment..

2、 Preparation basis: 1.

2.

2.

When other materials are used, it can be implemented with reference to this process standard on the basis of full consideration of material characteristics.

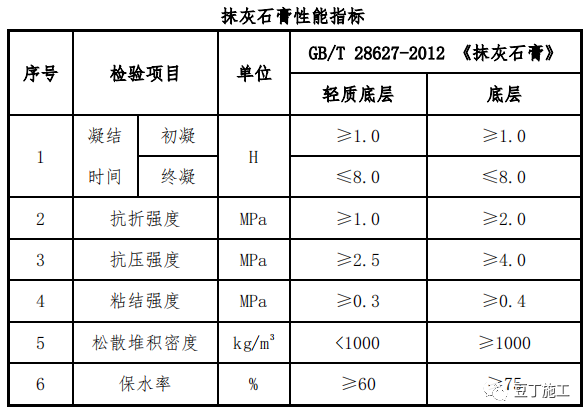

(2) according to the regulations of plastering gypsum (GB / t28627-2012), plastering gypsum is divided into bottom plastering gypsum, surface plastering gypsum, light bottom plastering gypsum, insulation plastering gypsum, etc.

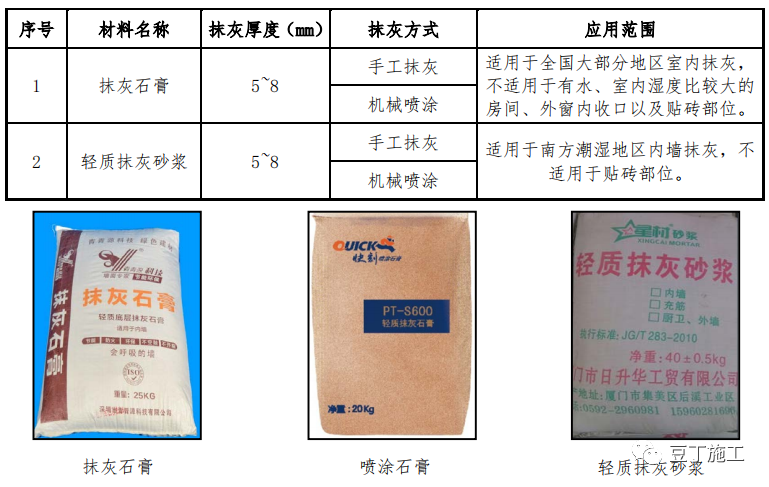

main materials, machines and tools ● materials ● thin plastering materials include plastering gypsum and light plastering mortar.

At present, light spraying plastering gypsum is widely used.

Technical specification for application of ready mixed mortar JGJ / t223-2010; 7 Technical specification for plastering mortar (JGJ / t220-2010) 8, construction specification for mechanical spraying plastering (JGJ / t105-2011) 9, concrete interface treatment agent (JC / t907-2018) 10, alkali resistant glass fiber mesh (JC / t841-2007) 11, technical specification for building light batten partition wall (JGJ / t157-2014) 12, autoclaved light mortar aerated concrete (AAC) block and batten building structure (06cj05) 13 Autoclaved aerated concrete block and plate structure 13j104 III.

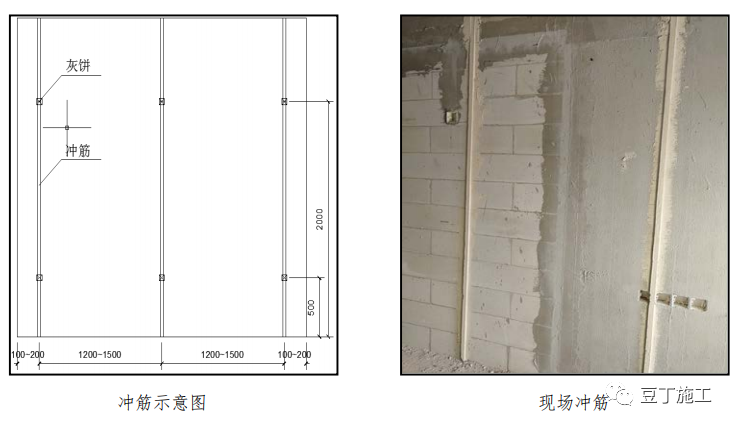

4、 Construction process flow of wall thin plastering this process takes plastering gypsum thin plastering as an example to introduce two plastering methods: manual plastering and mechanical spraying.

The dry density after preparation in proportion shall not be greater than 1200kg / m ³ Dry mixed mortar.

Except for mortar mixing and spraying, the process of mechanical spraying plastering is basically the same as that of manual plastering.

Mechanical spraying and plastering tools: except for the shotcrete machine, the mechanical spraying and plastering tools are basically the same as manual plastering, and can be used for general purpose.

(2) The secondary structure works of working face 1) have been completed and passed the acceptance.

2) According to the construction progress requirements, reasonably allocate construction personnel, machines and tools to enter the site for construction, and carry out three-level education for all construction personnel to implement safe and civilized construction.

Manual plastering tools: main tools: hand-held electric mixing gun, laser instrument, 1.5m aluminum alloy wedge scraper, plumb line, ink bucket, ash tray, batch knife and 2m aluminum alloy square scraper.

From | network data sorting | Douding construction I.

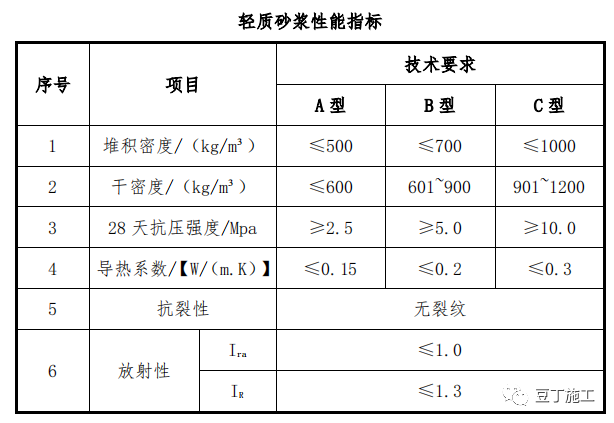

Its performance shall meet the requirements of light mortar JG / T} 521-2017.

The shelf life of bagged plastering gypsum is 6 months, and bulk plastering gypsum must be stored in a special closed silo with a shelf life of 3 months.

Mechanical spraying plastering gypsum JC / t2474-2018; 6.

Construction preparation (1) materials, personnel, machines and tools 1) arrange the production and material supply plan according to the construction schedule, implement the on-site stacking site, and take rain and moisture-proof measures.

(3) The plastering gypsum used for mechanical spraying must meet the performance requirements of mechanical spraying plastering gypsum (JC / t2474-2018).

1.

Light mortar JG / t521-2017; 5.

Requirements for retaining tongue and groove at shear wall end: (1) high precision formwork process + ordinary masonry: the reserved tongue and groove at shear wall end and beam side is 5mm ~ 10mm deep and 100mm wide; (2) high precision formwork process + strip: when the strip with U-shaped groove on the side is adopted, 5mm deep and 100mm wide groove shall be reserved at the end of the shear wall; When the strip with V-shaped tongue and groove on the side is adopted, no tongue and groove is left at the end of the shear wall; (3) high precision formwork process + high-precision masonry: shear wall does not leave tongue and groove.

● machines and tools 1.

Auxiliary tools: 50mm wide aluminum alloy square ruler (for window edge and external corner closing), temporary water tank or bucket, water pipe, ash bucket, steel tape, level ruler, line, pencil, etc.

It is forbidden to use expired and damp caked plaster.

Plastering gypsum GB / t28627-2012; 2.

1.

The materials of thin plastering process include plastering gypsum and light mortar, which are mainly used on the walls of bedroom, living room and dining room.

2.

Ready mixed mortar GB / t25181-2019; 3.

This process is applicable to residential and apartment projects constructed by the group with high-precision formwork (aluminum alloy formwork, large steel formwork, etc.) process of wall + internal partition strip / high-precision masonry.

4.

2) the through wall bolt holes on the wall of the main structure shall be blocked as required.

3.

Plastering gypsum (plastering gypsum) (1) it is a plastering material made of hemihydrate gypsum (CaSO4 • 1 / 2H2O) and type II anhydrous calcium sulfate (type II CaSO4) alone or mixed as the main cementitious material and admixtures.

The light plastering mortar (1) takes cement as the main cementitious material, fly ash, ceramsite, building recycled material, desert aeolian sand or machine-made sand as the aggregate, and the polymer additive as the modifying agent.

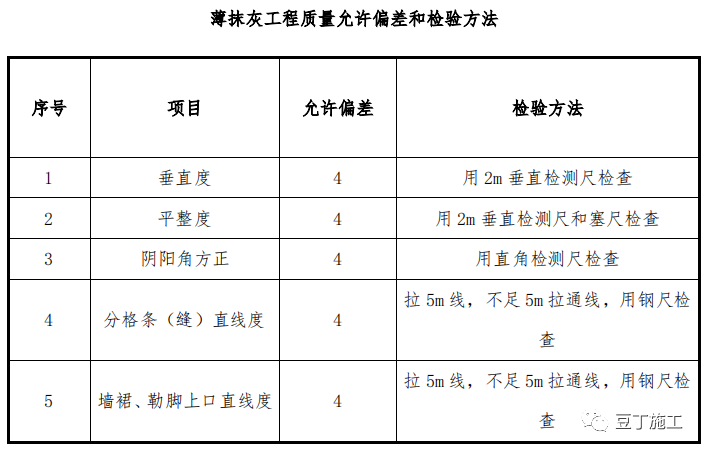

The deviation of wall axis position, perpendicularity and flatness meet the specification requirements.