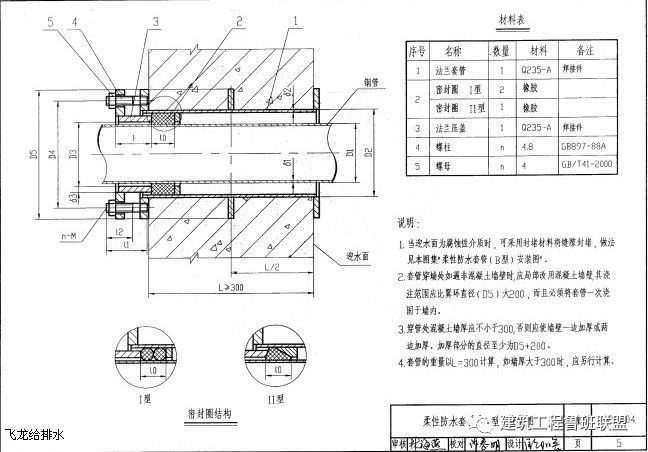

When the through wall pipe is connected with the inlet and outlet pipes of the pump or booster equipment, a flexible connection should be set at the connection.

Requirements for water filling of drainage pipeline: 1.

Test method: the test time is 2 ~ 3min, and the pressure does not drop and there is no leakage.

Code for acceptance of construction quality of building water supply, drainage and heating engineering is the most basic specification that should be followed in water supply, drainage and heating construction.

For buildings with strict waterproof requirements, flexible waterproof casing must be used.

2.

8.2.1 when the design is not indicated, the pipeline installation slope shall comply with the following provisions: (1) the slope of hot water heating pipeline with gas and water flowing in the same direction, steam pipeline and condensate pipeline with steam and water flowing in the same direction shall be 3 ‰ and shall not be less than 2 ‰; (2) The gradient of hot water heating pipeline with reverse flow of gas and water and steam pipeline with reverse flow of steam and water shall not be less than 5 ‰; (3) The slope of radiator branch pipe shall be 1%, and the slope direction shall be conducive to exhaust and drainage.

2.

Spray test of roof fire hydrant 6 # 5.2.1 the concealed or buried drainage pipeline must be subject to irrigation test before concealment, and the irrigation height shall not be lower than the upper edge of the bottom sanitary ware or the ground height of the bottom floor.

For areas with seismic fortification requirements, if rigid waterproof casing is adopted, flexible connection shall be set nearby on the pipeline entering the pool wall or the upper wall of the building.

At the same time, check that there is no leakage at all connections.

3.

After reaching the test pressure and stabilizing for 30min, the pipe network shall be free of leakage and deformation, and the pressure drop shall not be greater than 0.05Mpa.

2.

Hydraulic test requirements for mobilization test of fan coil unit: 1.

Hydrostatic test before installation of the whole set of radiators 9# 8.5.1 the buried part of the coil laid under the ground shall not have joints.

The tightness test pressure shall be the design working pressure, and there shall be no leakage after stabilizing for 24h.

It needs to be clear about it in construction and shall not be violated at will.

Observe the metal and composite pipeline system under the test pressure for 10min, the pressure drop shall not be greater than 0.02MPa, and then reduce it to the working pressure for inspection, and there shall be no leakage; The plastic pipe water supply system shall be stabilized for 1H under the test pressure, and the pressure drop shall not exceed 0.05Mpa, and then stabilized for 2h under the condition of 1.15 times the working pressure, and the pressure drop shall not exceed 0.03mpa.

It is a standard to ensure project safety, use function, human health, environmental benefits and public interests.

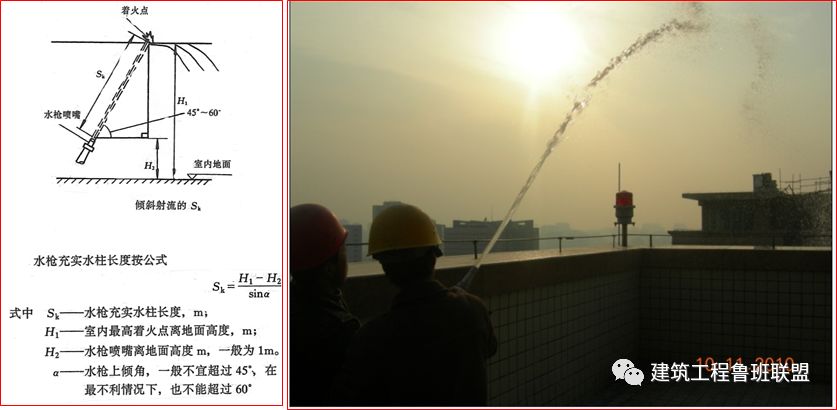

Enrich the length of water column: the length of a jet from the nozzle of the water gun until 90% of the water column of the jet passes through the circle with a diameter of 38cm.

Among them, 20 mandatory provisions are the bottom line of construction quality.

It is qualified if the water level does not drop for 15min, and then it is filled for 5min, the liquid level does not drop, and there is no leakage in the pipeline and interface.

Rigid waterproof casing is applicable to structures (buildings) where the pipeline passes through the wall and does not bear pipeline vibration and expansion deformation.

The water quality inspection report shall be issued after the water supply network is handed over.

When injecting water into the pipe network, the air in the pipe network shall be drained and the pressure shall be increased slowly.

1 # 3.3.3 if there are pipes passing through the outer wall of basement or underground structure, waterproof measures shall be taken.

The test point of the hydraulic strength test of the sprinkler system shall be set at the lowest point of the system pipe network.

For the installation of radiators, the 1% slope of branch pipes shall be 8 8.3.1 after the radiator is assembled, and the whole group of radiators leaving the factory shall be subject to hydrostatic test before installation.

4.

For low radiant heat pipe, the pressure drop shall not be greater than 0.05Mpa and there shall be no leakage within 1h under the test pressure.

The rainwater pipe shall be filled with water to the rainwater bucket at the upper part of each riser for 1H without leakage.

Installation requirements of rigid and flexible waterproof casing for exterior wall waterproof casing: 1.

Test method: the pressure drop within 1h of pressure stabilization shall not be greater than 0.05Mpa, and there shall be no leakage..

Type A is applicable to steel pipe, and type B and C are applicable to nodular cast iron pipe.

The coil shall be buried and concealed without joint # 10 # 8.5.2 before the coil is concealed, the hydrostatic test must be carried out, and the test pressure shall be 1.5 times of the working pressure, but shall not be less than 0.6MPa.

Inspection method: check on site before concealment.

The district and county centers for Disease Control and prevention shall conduct on-site sampling inspection and issue the test report.

3.

Inspection method: observe and measure with level ruler, stay wire and ruler.

The flexible waterproof casing is applicable to areas with seismic fortification requirements.

If there are no requirements in the design, the test pressure shall be 1.5 times of the working pressure, but shall not be less than 0.6MPa.

Test method: check the test report provided by relevant departments.

Irrigation test of rainwater pipe and sewage pipe after irrigation, the drainage pipe leaks, and the pipe leaks behind the ceiling.

The structural form of waterproof casing is divided into three types: flexible waterproof casing (A / b pipe type), rigid waterproof casing (A / B / C type) and rigid waterproof wing ring.

3.4.1.2 water supply pipes must adopt pipe fittings suitable for pipes, and the materials involved in domestic water supply system must meet the hygienic standard of drinking water.

The pipe passing through the wall bears vibration and pipe expansion deformation, or the outer wall of structures (buildings) with strict waterproof requirements.

5) 4.3.1 after the indoor fire hydrant system is installed, the test fire hydrant on the roof layer (or in the water tank room) and two fire hydrants on the first floor shall be taken for fire test, and it is qualified if it meets the design requirements.

Schematic diagram of flexible casing installation # 2 # 3.3.16 various pressure bearing pipeline systems and equipment shall be subject to hydrostatic test, and non pressure bearing pipeline systems and equipment shall be subject to water filling test.

Test method: field test.

The inspection report of the center for Disease Control and prevention of water supply pipeline # 4.2.3 the domestic water supply system pipeline must be washed and disinfected before being delivered for use, and can only be used after being sampled and inspected by relevant departments and meeting the national drinking water standard.

Test firing requirements: the elevation angle of the test firing is about 45 ~ 60 °, the length of the full water column is 10m for buildings below 100m, and 13m for buildings over 100m.