Installation process of latch type cork floor # 1.

10.

14.

7.

11.

Precautions before installation of cork floor # 1.

2.

There is no need to leave an expansion joint with the wall.

Protection of finished facade products: protect the edges and corners of furniture that may be encountered.

Coating the interface agent: roll coating the interface agent.

Cut the lower part of the gate to leave 10mm expansion joints along all walls of the floor.

This glue is consistent with the synthetic water-based environmental protection glue of cork floor, which ensures that the ground and the floor form a whole, and effectively prevents the floor from cracking, warping and bulging.

7.

In particular, pure cork floor is deeply loved by consumers because of its advantages of moisture-proof, no deformation and simple maintenance.

Check whether the wall is straight..

Dry: it means that the ground humidity shall be less than 20%, and there shall be no moisture or leakage.

Self leveling cement polishing and dust collection: polish the self leveling cement, remove the burr or individual height difference on the surface of the self leveling cement, conduct further fine leveling, dust collection on the ground, and make preparations before gluing.

Repair of rough ground: find out the defects of the original ground and chisel it carefully.

4.

Under the action of the rotating force of the mixing head, the self leveling cement can be mixed more evenly and finely.

Installation equipment of cork floor # grinder, vacuum cleaner, self leveling cement mixer, scraper, vent cylinder, nail floor, flat scraper, rubber scraper, plate cutter, rubber hammer, mixing barrel Air release roller ^ installation process flow of adhesive cork floor ^ 1.

If it is longer than this distance, pressure strip shall be added for partition.

Firm: the foundation is firm without looseness, and the strength and thickness of the ground foundation shall meet the requirements of House acceptance.

5.

5.

8.

In order to better isolate temperature and reduce noise, lay 2mm thick cork cushion (recommended).

Protective fluid: maintain the floor.

Here, Xiaobian specially sorted out the installation and construction process of cork floor, hoping to help the majority of cork pavers.

Clean: No floating soil, no obvious construction waste, etc.

Abstract: cork floor is favored by more and more consumers because of its special use performance and personalized decoration effect.

3.

The following introduces the installation method of pure cork floor.

Floor pavement shall be carried out after the completion and acceptance of ground concealed works, ceiling works, wall works and hydropower works.

The overlap between the two films is required to be 20cm, and it is required to be 5cm higher when encountering the wall.

Grinding and dust collection of rough ground: grind the ground with a grinder to accurately the flatness of the ground and control the error with the surrounding ground within 2.0mm.

The indoor ambient temperature should be above 10 ℃.

5.

When installing the floor, it should be laid along the direction of light entering the window.

There is no cross construction on the installation site and no special construction restrictions.

Lay moisture-proof film.

3.

The whole ground is a whole.

2.

However, as we all know, “three floors and seven installation”.

The loss of cork floor varies according to the size and shape of the room and whether there are special-shaped structures (such as floor, partition, etc.).

Rough floor cleaning: remove the protrusions such as gypsum, paint and cement hard blocks on the ground with a special blade, and dust the original ground without leaving dust debris to make the floor cleaner.

Adhesive cork floor self leveling cement finished product height is 3mm, floor height is 4mm, a total of 7mm, latch type moisture-proof floor pad is 3mm, floor height is 11mm, a total of 14mm.

Harrow self leveling cement: harrow self leveling cement: the cement shall be poured into the construction site as soon as possible after mixing, so that the harrow can evenly control the construction thickness of self leveling cement under the condition of no wind.

Preparation before installation of cork floor # 1.

4.

There are two kinds of cork floor.

Gluing: roll coating professional water-based environmental protection glue, first manually coating the wall corner, and then roll coating.

9.

The construction personnel must wear nail shoes to improve the strength and quality of self leveling cement.

After raking, the exhaust barrel shall be used for air exhaust treatment as soon as possible.

Installation of skirting line: specially equipped skirting line shall be installed to keep the color of floor and wall harmonious and unified.

3.

Flatness: check the flatness of the ground with 2m guiding rule, and the maximum chord height between the guiding rule and the ground shall be ≤ 3mm.

6.

4.

If the paving process is unreasonable, the best advantage of the floor itself can not be brought into play.

Requirements for the ground: clean, dry, flat and firm.

The maximum length of continuous laying of latch type cork floor is 7-8 meters.

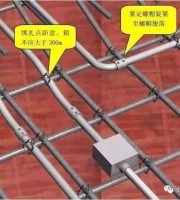

Fixing Socket Cross Hole Nail Plate

In order to improve the flatness of the original ground, it is necessary to avoid omission.

12.

Scribing installation: pave from the middle to both sides according to the planned line, perfect the paving pattern and reduce the loss.

This is the best dissolving agent for the original ground and self leveling cement to ensure that the surface base course is closely bonded with self leveling cement and has a certain moisture-proof function.

Generally speaking, the loss of square and large rooms is small, which is generally less than 5%, generally 3-5%, and the loss of individual special-shaped structures may exceed 5%.

Preparation of installation materials # interface agent, self leveling cement, protective fluid, special glue for cork floor # 2.

6.

13.

One is to stick cork layer on both sides of laminate floor, and the paving method is the same as that of ordinary laminate floor; The other is 4mm thick pure cork floor, which can be directly glued to the ground.

First, manually coating the wall corner.

There is no distance limit for the laying of adhesive cork floor, and there is no need to separate sections.

Self leveling cement exhaust: exhaust the self leveling cement.

Mixing self leveling cement: when mixing self leveling cement, professional tools must be used to mix self leveling cement.

2.

Customers should properly reserve according to the height of the contact part between cork floor and other floors higher than the finished floor, especially door pocket, wall corner, heating cover and other irregular details.

Coating special finish: roll coating the floor surface with special paint for cork floor after paving, which is conducive to further improving the wear resistance and waterproof performance of the floor surface.