Therefore, starting today, I will share with you the construction organization design of solar cell production projects.

(2) the reserved opening is less than 1.5m × 1.5m greater than 0.5m × The protection of 0.5m shall be operated according to the following figure.

Thank # Wenmeng for pursuing excellence and Zhai Lijuan for sharing the materials.

The protective fence can be used after being accepted and signed, See the following figure for the erection requirements: more contents: 1 – project overview 2 – wastewater treatment station 3 – bulk gas station 4 – construction objectives 5 – high-altitude operation 6 – overall arrangement of project implementation 7 – arrangement of construction team 8 – main construction stage 9 – construction method of divisional and subdivisional works 10 – elevation measurement control 11 – settlement observation 12 – Installation of embedded anchor bolts 13 – Determination of bolt position 14 – formwork removal Concrete curing 15 – Super leveling professional construction 16 – floor construction process 17 – film covering and protection 18 – formwork installation 19 – concrete pouring 20 – concrete surface treatment 21 – steel structure fabrication 22 – detail design 23 – connection node design 24 – steel structure fabrication process 25 – steel structure processing and fabrication process 26 – setting out Allowable deviation of template 27 allowable deviation of steel after correction 28 allowable deviation of cutting 29 allowable deviation of sawing 30 allowable deviation of refined bolt hole 32 allowable deviation of bolt hole spacing 33 assembly principle 34 principle of steel plate splicing 35 allowable deviation of welded structure assembly 36 H-shaped steel assembly 37 welding H-shaped steel column production 38 welding process flow chart of steel structure 40 welding rod Table 41 – General Provisions for welding flux selection 42 – automatic submerged arc welding 43 – CO2 gas shielded welding 44 – carbon arc gouging 45 – welding sequence 46 – member derusting method and inspection standard 47 – steel member coating method 48 – derusting and repair of coating defects 49 – Parts prohibited from painting 50 – finished product protection and transportation 51 – steel structure installation 52 – hoisting of steel columns 53 – roof truss installation and construction 54 – high strength bolt installation 55 – profiled roof panel installation 5 6 – positioning of fixed support 57 – precautions for installation 58 – Installation of sandwich color plate wallboard 59 – coating of fire retardant coating for steel structure 60 – binding of beam and plate reinforcement 61 – binding of column reinforcement 62 – column formwork 63 – beam, plate formwork 64 – stair formwork 65 – precautions for construction of wood plywood formwork 66 – concrete engineering 67 – beam Slab concrete 68 – concrete curing 69 – masonry construction 70 – roof waterproof construction 71 – plastering construction 72 – emulsion paint wall construction 73 – ceiling construction 74 – penetration crystallization wear-resistant floor construction 75 – floor tile floor construction 76 – epoxy floor construction 77 – rolling shutter door installation 78 – aluminum alloy window installation 79 – water supply pipe installation 80 – drainage pipe installation 81 – electrical piping and threading in pipe 82 – lightning protection and grounding engineering 83 – construction schedule 84 – construction progress control flow chart 85 – resource assurance measures 86 – technical measures 87 – management measures 88 – quality management organization structure 89 – quality management responsibilities 90 – quality education system 91 – acceptance and technical review of concealed works 92 – three-level inspection and process handover 93 – quality management of operators 94 – quality management of raw materials 95 – Measurement and earthwork 96 – reinforcement works 97 – formwork works 98 – concrete works 99 – steel structure Project 100 – masonry works 101 – doors and windows, floor works 102 – plastering works 103 – installation works 104 – major hazard sources 105 – safety management network diagram 106 – personnel function distribution table 107 – establishment Improve the safety education system 108 – ensure that special operations are employed with certificates 109 – handling of industrial accidents 110 – temporary electricity 111 – on-site lighting 112 – electric box (distribution box and switch box) 113 – hand-held electric tools and electric welding machines 114 – external scaffold and support scaffold 115 – mobile scaffold 116 – five edge protection 117 – four port protection, more purified communication groups, recognize and implement group regulations, Welcome to “purify the four groups and follow the rules” (open the link to see the details.) For more purification materials, please refer to “borrow 69 purification materials for free 20211130”, “share 2 yuan for 36 purification materials”, “video, audio and articles, here’s all the purification you want”, whether it’s “like the author” or forwarding, or even opening the advertisements automatically added in and behind the text, Can add a “Shandong big steamed bread” to Xiaobian********************** Chat up Xiaobian..

Solar power stations, solar water heaters, electric vehicles and energy storage power stations are all based on the mass production of batteries, and the production of solar cells is the demand side of purification projects.

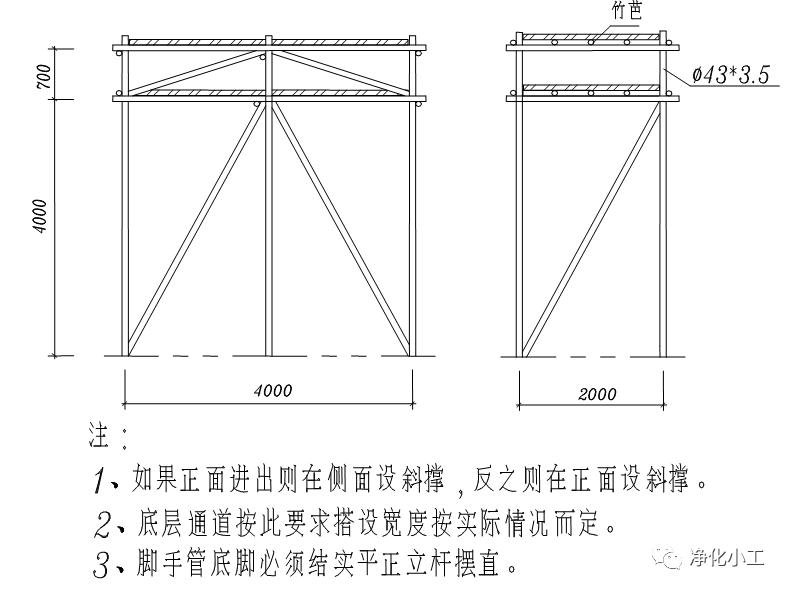

(4) a double-layer protective fence shall be set up at the entrance and exit of the protective derrick of the construction channel and the main entrance and exit of the bottom layer of the building.

(3) the reserved opening is greater than 1.5m × The protection of 1.5m shall be operated according to the following figure.

7.4.5.2 protection of four openings (1) reserved opening less than 0.5m × The protection of 0.5m is adopted according to the following figure.