The structure is reasonable, solid and durable.

The elastic joint is firmly consolidated: the side beam and middle beam of the elastic joint are made of 16Mn steel, which can accept the straight load and horizontal impact of large flow and large tonnage vehicles.

Z80 bridge expansion joint 3 Smooth bridge deck and comfortable driving: the elastic joint equipment can not only ensure the free elastic displacement of the beam body, but also make the bridge deck joints form a smooth whole, and the driving is stable and comfortable.

The anchored components are firmly welded with the embedded reinforcement of the expansion joint of the beam body and abutment Z80 bridge, which can reliably transfer the vehicle load to the pier and abutment.

When the bridge deck asphalt concrete pavement is completed and accepted, we can determine the slotting width according to the requirements of the elastic joint construction drawing, set out accurately, and saw the joint and straighten it with a cutting machine after it is set on the line, The asphalt concrete pavement beyond the sawing line needs to be set up.

It is necessary to carefully cover it with plastic cloth and seal it with rubber Z80 type bridge expansion joint tape to prevent the stone powder from polluting the pavement during sawing.

18232937111z80 bridge expansion joint manufacturer’s construction report Z80 bridge expansion joint equipment and methods of bridge expansion joint: first, the bridge deck is cut.

1.

4.

2.

It is suitable for the bridge with the planned load of steam – exceeding 20 and hanging – 120.

Processed according to the width of the bridge, it has excellent elastic deformation, waterproof and dustproof functions of Z80 bridge expansion joint; It can effectively protect the internal components of elastic equipment and the support at the beam bottom from corrosion.

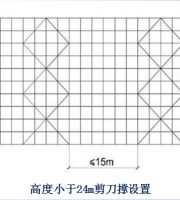

Large displacement and easy selection: the displacement of the equipment is manufactured according to the modulus planning, from 80 to 1200mm.

The planning and construction part of the bridge can be freely selected according to the practical elasticity of the bridge superstructure…

5.

Water stop and corrosion prevention: Neoprene sealing strip embedded in each group of steel beam groove.

The elastic seam has the characteristics of elastic flexibility: the displacement control system of multiple groups of seams of the equipment is composed of elastic elements such as rubber tension spring, tetrafluoro pressure bearing support or inclined support components, with uniform displacement and small elastic friction resistance.