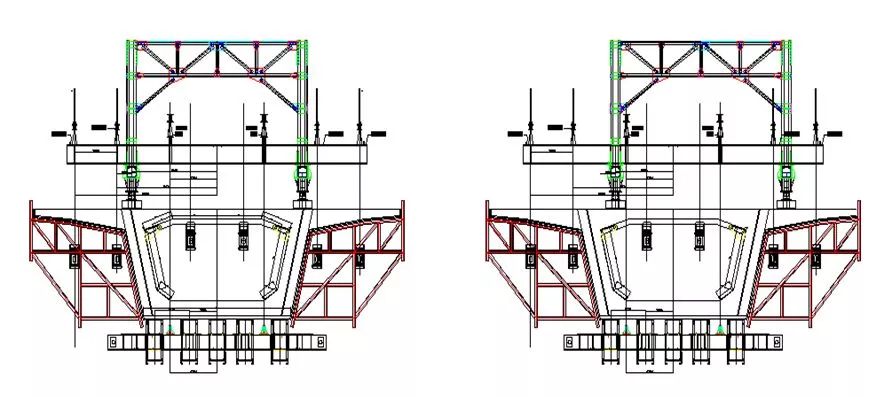

⑥ Formwork system: composed of internal formwork, side formwork and bottom formwork.

Triangular hanging basket rhombic hanging basket bow string hanging basket (IV) structure of triangular hanging basket triangular hanging basket is composed of six parts: ① main truss system, ② traveling system, ③ anchoring system, ④ hanging system, ⑤ working platform system and ⑥ formwork system.

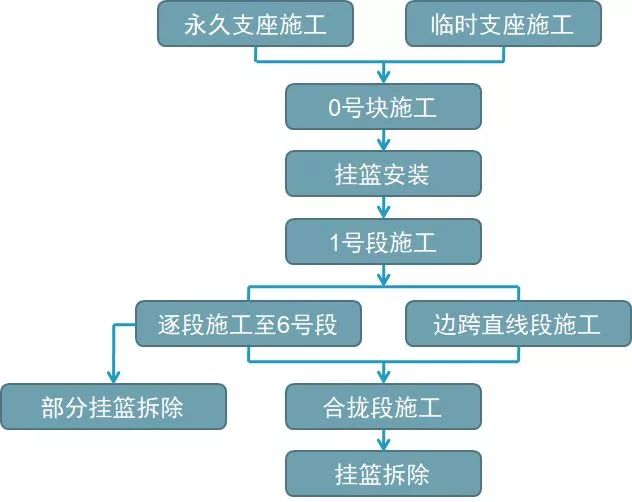

4.

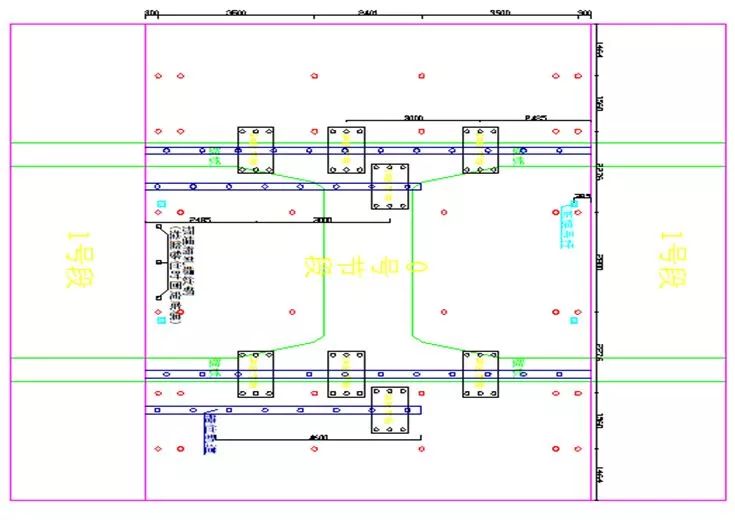

Temporary consolidation and support installation} bottom formwork laying and side formwork installation of 6 and 0# sections: the side formwork adopts large shaped steel formwork, which is installed manually with truck crane and chain fall.

0 # section reinforcement installation 8.

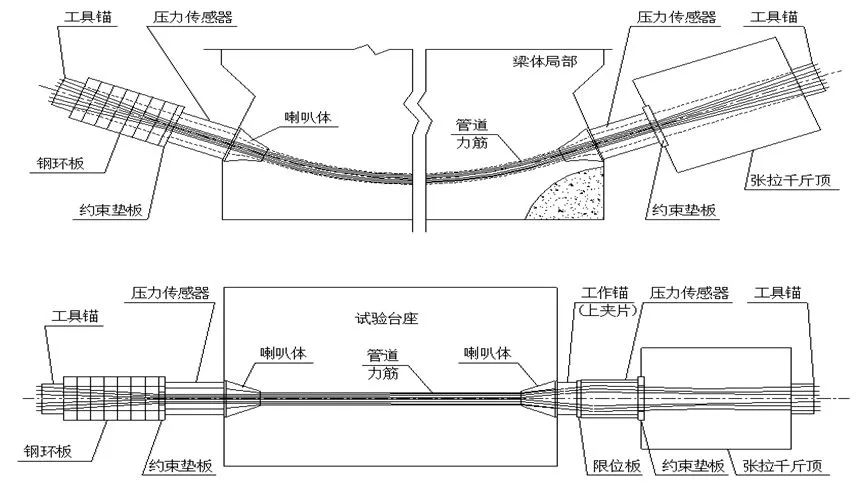

Prestressed reverse fulcrum preloading 3.

Support installation: the surface of the support pad stone shall be roughened before installation.

For the steel pipe with wall thickness of 10mm, the steel pipe support is connected with L50 angle steel as cross bridging to form a whole, so as to ensure the overall stability of the support.

Concrete pouring: ⑴ check and adjust the formwork elevation, reinforcement, prestressed duct layout, embedded parts embedding and reinforcement and support stability before pouring.

Temporary consolidation: C50 concrete pouring is adopted, and 72 buttresses and beams are adopted Φ 32 finish rolled deformed steel bar anchor connection.

③ Anchorage system: it is divided into two parts: the anchorage of the main truss and the anchorage of the platform system φ 32.

10 supports are used for erection Φ 1020.

2、 Main process flow of hanging basket construction technology diagram of construction sequence of pile continuous beam pouring basket (I) the pouring 0# section of 0# section is located above the pier, and the pouring 0# section is equivalent to providing an installation site for hanging basket.

9.

It can make full use of the bearing platform foundation, embed bolts on the bearing platform, and lay 20mm thick flange backing plate to connect the bearing platform and steel pipe pile.

Compared with other methods, hanging basket construction has the advantages of light structure, simple and convenient assembly, no weight and so on.

Unlike the traditional surcharge preloading, the prestressed reverse fulcrum preloading is selected for the span Yangwan continuous beam, which is simple, efficient and easy to simulate the real stress state.

It does not require the erection of supports and the use of large cranes.

Steel pipe pile support erection 2.

All post suspenders need to reserve holes on the completed beam body.

After completing the circulation of one section, the hanging basket can be moved forward and fixed to carry out the cantilever grouting of the next section, and such circulation will continue until the cantilever grouting is completed.

④ Hanging system: it is mainly composed of finish rolling threaded suspender, sling, small distribution beam, adjusting jack, etc.

Schematic diagram of anchoring and embedding of steel strand the embossed reverse fulcrum preloading method of steel strand is to apply the reaction force to the support by tensioning the steel strand (or finish rolling deformed steel bar, etc.), so that the reaction force is equal to the preloading load, so as to eliminate the inelastic deformation of the whole support, obtain the elastic deformation and determine the camber.

0 # section end formwork installation: custom steel formwork is adopted and assembled on site.

Installation of end formwork of 0# section and internal formwork of 0# section 10.

Prestressed pipe installation 11.

⑤ Working platform system: mainly composed of front lower beam, rear lower beam, bottom formwork flower rack, etc.

Reinforcement installation: after the bottom formwork is positioned, install the bottom plate reinforcement, web reinforcement, prestressed bellows and reserved holes, erect the inner formwork, install the top plate reinforcement and place embedded parts.

Duct use φ 10mm steel bar “well” shaped reinforcement, and its deviation shall not exceed 2mm.

Installation of 0# section outer formwork 7.

(2) The main work contents of hanging basket cantilever construction include: pouring the starting beam section (0# block) on the pier top, assembling the hanging pouring hanging basket on the starting beam section, and pouring the hanging beam section in sections in turn; Finally, the side span and middle span are closed.

(1) Hanging basket structure hanging basket is a load-bearing frame that can slide or roll along the beam top.

The fine bound threaded reinforcement is anchored on the box girder.

① Main truss system: it is mainly composed of triangular main truss and front upper beam, and its members are welded from section steel.

Installation of prestressed pipeline: the prestressed duct shall be accurately positioned and firmly reinforced.

During installation, attention shall be paid to the support type, plane position, support pre deviation, etc.

Installation of 0# section internal formwork: self made wood formwork is used, supported by steel pipe support, and the beam bottom plate is supported by 10# channel steel.

On the hanging basket, the installation of formwork, reinforcement and prestressed pipeline of the next beam section, concrete pouring, prestressed tensioning, grouting and other operations can be carried out.

The 0# section adopts cast-in-situ steel pipe pile support, which has the advantages of high construction height, simple operation and fast efficiency.

According to the design drawing of the hanging basket and considering the position of the embedded parts of the beam such as bellows, determine the reserved hole position of the rear anchor and the rear suspender.

It is used to support the platform system, transfer its load to the main bearing system, and adjust the suspender nut by operating the jack to adjust the platform elevation.

![]()

Laying of bottom formwork of 0# section: 6mm thick steel plate is fully paved on the support distribution beam.

5.

The front end of the platform system is anchored on the front upper beam through finish rolled threaded suspenders and suspenders.

After the support erection is completed, it must be preloaded according to the specifications.

Embedded drawing of hanging basket hoisting system 12.

The bellows shall be straight without sharp bend or deviation.

Use a high-pressure air gun to remove the sundries on the bottom plate and spray water on the formwork to wet it..

1.

The so-called cantilever basket refers to the cantilever construction method, which refers to the cantilever construction in situ.

1、 Introduction of hanging basket hanging basket is widely used for cantilever pouring construction of long-span prestressed concrete continuous beams.

It is anchored and suspended on the constructed beam section.

Post anchor embedding and suspender hole embedding Construction: finish rolled deformed steel bar and hanging basket for post anchor.

(3) Generally, truss type hanging baskets can be divided into triangle hanging baskets, diamond hanging baskets, bow string hanging baskets and flat string hanging baskets without balance weight; (32 + 48 + 32) m continuous beam adopts triangular hanging basket, which has the advantages of simple structure, light self weight, clear stress, good stability and small deformation.

② Traveling system: it is mainly composed of guide chain, traveling track, traveling beam of internal and external formwork, front sliding seat, rear hook seat, etc.