In order to avoid accidents, we should pay attention to the construction quality in the construction, start with the details, and don’t cause heavy losses because of a small detail.

Elevation marks shall be set on the top of the formwork, and the construction shall be carried out in strict accordance with the marks.

After the reinforcement is bound, wash the formwork with high-pressure water to remove the garbage in the formwork.

The thickness of the decorative layer shall be considered when installing the stair step formwork.

12 formwork residues cause cracks, and construction wastes such as wood blocks, laitance residues and gravel remain in the formwork.

Construction waste such as wood blocks, laitance residues and gravel are left in the formwork.

In fact, construction technology is the key point, but the problems of building material procurement, cost evaluation and site layout in construction organization design also need to be reflected in the construction scheme.

During drawing review, it is necessary to ensure that all disciplines strengthen communication in many aspects during design and review, so as to avoid “fighting” of pipelines during construction, change and waste of construction period.

Before sealing the mold, send someone to clean up the garbage in the mold.

In order to ensure that the drawings play a guiding role in the construction, it is necessary to communicate with the design department to discuss the solutions of nodes that are difficult to construct, and modify them if necessary.

08 rebar hook for tensile grade HPB 235300 rebar, 180 hooks shall be made at its end.

Then the problem comes, how to avoid it? What are the mistakes in the construction? How? Let’s get up and have a look! Drawing review lesson 01 building structure drawing is not clear.

Cleaning holes shall be reserved at the beam column joints at the root of the wall column, and the cleaning holes shall be closed in time after the garbage in the formwork is removed.

13 elevation deviation: it is found that the elevation of concrete structure layer signs, embedded parts and reserved holes deviates from the design elevation of the construction drawing.

The buckles shall be inward and shall not be buckled in the same direction.

The scaffold project 17 lacks safety protection.

However, when these two types of reinforcement are compressed, hooks may not be made.

For the intersection of two rows of one-way slabs near the periphery, each point is required to be bound.

In addition, the inner diameter of the bending arc shall not be less than 2.5D (D is the diameter of the reinforcement), and the length of the straight part of the hook shall not be less than 3D.

When reviewing the drawing, we should avoid the problem of unclear structure drawing.

The plate should be watered and wetted in advance, so as to expand the tight joint.

At the site of beam column handover, the support shall be firm, the joint shall be tight, and the dislocation shall be corrected.

10 if the reinforcement is not bound firmly, there shall be no less than 3 BUCKLES within the overlapping length of the reinforcement.

If there is any abnormality, find out the cause from the aspects of measurement, materials, mix proportion, etc.

The longitudinal reinforcement spacing of beam, column and shear wall shall be considered.

In order to avoid elevation deviation, sufficient elevation control points shall be set on each floor, and the root of formwork erection shall be leveled.

The moisture content of formwork shall be strictly controlled and the joint shall be tight.

04 errors and omissions of reserved holes and embedded parts common errors and omissions of reserved holes and embedded parts lead to the demolition and modification of later structures, resulting in unnecessary costs.

In addition, the rubber pad in the middle part can be bound at intervals, but for the stressed reinforcement of two-way slab, it is required that all reinforcement intersections should be bound firmly.

Production technicians who fail to pass the material inspection shall timely check the material condition and test results, timely adjust the production mix proportion, sand moisture content, stone content in sand, thickness and weather conditions, and properly adjust the benchmark mix proportion.

When reviewing the drawings, we should look at the structure in combination with the building, focus on checking the elevation, axis number and other information, and compare them from different angles.

The water cement ratio and cement dosage of concrete works 14 are unreasonable.

Ensure that the intersection of stirrup and main reinforcement is close to each column when binding.

The maximum water cement ratio of concrete shall not exceed 0.55, the maximum cement dosage shall not exceed 500kg / M (including the mixture replacing some cement), the mass concrete shall not exceed 350kg / m, and the minimum cement dosage shall not be less than 250kg / m.

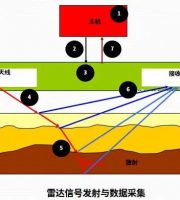

03 crossing problems of professional pipelines collision will occur when water, electricity, heating and other professional pipelines cross.

After formwork removal, cracks and garbage inclusions are found in the concrete.

06 the plan is inconsistent with the reality.

The communication between the technical department and the economic department should be strengthened to avoid budget quota, cost control and other factors restricting the actual construction.

After formwork removal, cracks, garbage and sundries appear in the concrete.

The group design class 05 lacks planning and communication, and the construction organization design is not only a technical management work.

The detailed location is unreasonable, and there are some problems in the specific practice drawing, such as inconsistent description with the specification, unreasonable node design and so on.

Due to the fact that the construction organization design scheme preparers of some construction units copy the specifications and other contents, the project department lacks effective management, and the reference and guidance for the construction organization design are not strong.

In the drawing design, we should strengthen the coordination between civil engineering and installation, water, electricity, heating and other disciplines, determine the specific position reserved, and review it before construction, so as to eliminate the demolition and modification in the later stage.

Specifically, the architectural drawings do not correspond to the structural drawings, and the descriptions of the architectural and structural drawings are contradictory or unclear.

The axis position does not correspond; There are some problems, such as inconsistent beam and column sizes and inconsistent wall thickness of brick concrete structure.

The longitudinal reinforcement spacing of some engineering categories is unreasonable.

The cost factor in the construction organization design must be considered and implemented.

When the scaffold is set higher than the top of the building under construction, the inner row upright shall be 40 ~ 50mm lower than the opening, and the outer row upright shall be 1 ~ 1.5m higher than the opening..

There is a separation between design and construction, resulting in the mere formality of the construction organization design.

15 the concrete mixture lacking consistency shall be mixed evenly, the color shall be consistent, and there shall be no segregation and bleeding.

Formwork 11 formwork mortar leakage due to the lax joints and gaps between the formwork, mortar leakage occurs during concrete pouring, and honeycomb appears on the concrete surface, resulting in serious holes and exposed reinforcement.

09 the steel buckle is missing.

At the same time, the reinforcement shall not be displaced and shall not be missed.

It is forbidden to raise the elevation of the building floor layer by layer.

If there is a two-way stressed reinforcement, pay attention to all intersections of the bound reinforcement when binding.

16.