For the supports and hangers installed that do not meet the specification requirements, they should be resolutely rectified in place.

The seismic supports and hangers must be installed in strict accordance with the points in the drawing.

Therefore, the galvanized support and hanger with the effective anti-corrosion treatment shall be used in the underground environment.

If there is infringement contact, delete # construction preparation 01.

3.

02 quality control of seismic support and hanger installation quality control in site construction is mainly divided into the following aspects: 2.1 Do a good job of technical disclosure in the installation of seismic supports and hangers.

Construction preparation: prepare corresponding construction tools and safety protection equipment.

The surface is treated with electro galvanized or powder zinc impregnated anti-corrosion coating.

For the seismic supports and hangers of fire protection system (fire sprinkler, fire hydrant system and smoke control and exhaust), the products shall pass the fire resistance test of fire protection products, and the fire resistance time shall not be less than 90 minutes.

03 material preparation prepare the required materials, components and accessories according to the quantities in the drawings, and negotiate the mobilization time node, mobilization route and storage location of goods with the receiving unit in combination with the overall progress of the project.

Positioning and setting out: according to the construction drawings, measure the size on site and find the point.

3 effective measures to ensure the installation progress and quality of anti-seismic supports and hangers 01 progress control of anti-seismic supports and hangers installation because there are many electromechanical subsystems involved in anti-seismic supports and hangers, it is very important to grasp the mobilization time node.

The angle of each diagonal brace must meet the specification requirements.

2.

02 prepare documents and prepare reasonable construction scheme according to the drawings and in combination with the actual situation of on-site pipeline installation.

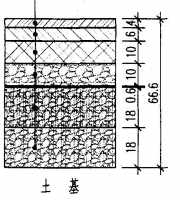

The galvanized support and hanger with the thickness of 275g or less shall be used in the underground environment.

If the mobilization is early, there may be no working face, resulting in unnecessary slowdown, and the dilemma that the installation cannot be carried out too late.

The mechanical properties of ordinary concrete expansive anchor bolt can meet the use requirements.

Adjustment of anti-seismic supports and hangers: during installation, adjust the parts that do not meet the requirements to meet the standard requirements; 7.

The installation process is as follows: construction preparation ➨ preparation of materials ➨ positioning and setting out ➨ cutting materials ➨ prefabrication of supports and hangers ➨ support installation ➨ support adjustment ➨ inspection after installation 3.2 Key points to pay attention to during installation: 1.

Find out the situation of the project, review the project quantities, compare the detailed drawings of each node, and prepare the corresponding installation scheme in advance for places with great construction difficulties.

After the installation of a batch of anti-seismic supports and hangers on the construction site, the installation personnel should first conduct self inspection, then inspect by other teams, and finally conduct final inspection by the on-site personnel.

The principle of model first shall be adhered to for the installation of model.

During the installation of seismic supports and hangers, technical disclosure shall be carried out to the construction personnel, so that the construction personnel can master the technical requirements that should be followed in the installation of seismic supports and hangers.

The thickness of the anti-seismic pipe clamp shall not be less than 5mm and the width shall not be less than 40mm, so as to ensure that the pipe clamp cannot be easily deformed under the earthquake force.

The effective anchoring depth of anchor bolt used for seismic support and hanger shall be 80mm-100mm.

The surface shall be treated with electro galvanized anti-corrosion treatment, and the thickness of galvanized layer shall not be less than 10 μ m。 5.

The strength of the screw shall not be lower than grade 4.8.

The bolts used shall be reliably connected with the structure to ensure that all components are fastened and reliable.

4.

The spacing between points shall not be adjusted or reduced without authorization.

2.2 strictly implement the three inspection system during construction.

Post installation inspection: strictly follow the three inspection system to ensure the installation quality of seismic supports and hangers; 3.1.

5.

In order to ensure the stiffness of seismic supports and hangers and reduce deformation, the section of channel steel shall not be less than 41 * 41mm.

Therefore, field investigation shall be conducted in the early stage of installation, and the corresponding time nodes shall be determined based on the overall schedule of the project and the schedule of each subsystem to ensure the construction progress.

4.

The inner edge of cold-formed U-channel steel of seismic support and hanger must have conical teeth with a depth of no less than 0.9mm, so as to ensure that the installation of all accessories depends on mechanical bite to realize stress conduction.

Sort out the source network.

6.

The material shall not be less than Q235, and the wall thickness of channel steel shall be ≥ 2.0mm to ensure sufficient shear stress.

It is strictly prohibited to use any installation method to bear the stress by the friction of accessories, so as to ensure the reliable connection of the whole system.

Professional manufacturers need to re conduct mechanical calculation and select appropriate support types according to the on-site pipeline, so as to meet the seismic stress requirements of the on-site pipeline..

Before getting familiar with the construction drawings, first understand the deepening drawings in detail, and review the calculation sheet and check calculation sheet.

The galvanized support and hanger with the thickness of hot-dip galvanizing shall meet the requirements of anti-seismic treatment.

Cutting and drilling: cut the material according to the measured size and drill holes at the corresponding positions.

03 installation process flow the installation process of seismic supports and hangers is basically as follows: 1.

04 technical disclosure materials shall be mobilized.

Installation of seismic supports and hangers: connect all components and accessories in place according to the specification requirements to ensure reliable connection between supports and structures.

If there are special needs, it is preferred to use reamed mechanical anchor bolt with mechanical locking effect suitable for concrete cracking area (including self cutting reaming anchor bolt and post cutting reaming anchor bolt), The strength of steel is divided into grade 4.8, grade 6.8 and grade 8.8 steel with high strength.

Pre support of seismic supports and hangers: pre support relevant components, fittings and channel steel at the point.

The full tooth screw and hex nut shall be made of Q235 steel specified in the national standard carbon structural steel GB / T700.

However, in practice, the on-site pipeline often changes, resulting in the phenomenon that the on-site pipeline is inconsistent with the drawings.

6.

After the mobilization acceptance, the team shall be organized to conduct on-site investigation in time, and the technical disclosure shall be conducted to the team leader.

The galvanized support and hanger with the thickness of 275g or less shall be used in the underground environment μ m.

2.

The thickness of zinc coating is ≥ 45um, and there is a bearing capacity test report issued by the national authority to meet the bearing capacity requirements of the joints; 3.