The junction between the formwork and the structural surface is blocked with plastic film + cement mortar, and the water is led out of the shaft for centralized discharge.

The intercepting layer refers to the first floor of the climbing frame and each floor of the basement with a climb of more than 5 floors.

blocking and intercepting parts: floor setting out hole, material transfer port, flue hole, air shaft and pump pipe hole; Basement tower crane opening, equipment hoisting opening, air shaft, skylight, etc.

(2) Water interception and drainage of elevator shaft water interception and drainage of elevator shaft: there are many water sources in the elevator shaft, and the drainage method is adopted.

Water interception and blocking parts in the wet operation area (1) water interception and blocking of tower crane openings, equipment hoisting openings and skylights shall be blocked on the top plate of the basement or other floors.

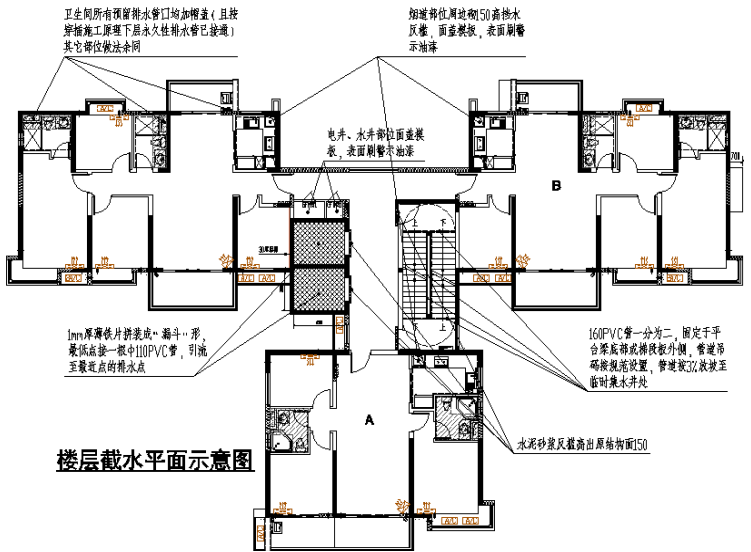

The installation of water and electricity has been inserted, the permanent drainage under the toilet has been installed, and the process of backfilling, leveling and waterproof shall be completed according to the requirements of the drawing.

The finished U-shaped interceptor can be purchased, which is continuously arranged around the outer wall, with a slope of 1%, and a drainage pipe is added at the lowest point to drain to the nearest catchment point.

No.3 improvement measures 1.

The water cut-off part includes the above ground floor stairs, balconies, toilets, reserved openings and external walls of each floor structure, tower crane openings in the basement, equipment hoisting openings, air shafts, water and electricity wells, skylights, etc; The method of water interception adopts blocking, closure and drainage system.

Drainage position of water interception system in dry operation area: temporary construction water connection point on the floor.

50 mm wide and 2 / 3 plate thick groove shall be reserved around each reserved hole, and the finished reinforced concrete cover plate shall be embedded and caulked with ointment.

III.

The reinforcement of precast cover plate is the same as that of floor slab.

soft connection shall be adopted at the junction between the turnover plate of the walkway plate at the bottom of the climbing frame and the external wall, which shall be continuously arranged along the walkway plate of the climbing frame to drain the water to the nearest water collection point and discharge it through the permanent drainage pipe of the floor.

Due to the shaking of the pump pipe in varying degrees during concrete pouring, the formwork is covered and wrapped tightly with soft materials along the circumference of the pump pipe, and then turned around the formwork to facilitate the drainage of water on the pump pipe.

2.

(4) Water interception and drainage of stairs and water interception and drainage of stairwell: a 200mm diameter PVC pipe is set in the middle of the beam bottom of the stair rest platform and the edge of the stair step plate.

No.2 cause analysis ― as an important part of the rapid construction system, the water interception of the outer wall floor intercepts the pollution of the completed works of the outer wall caused by the construction of the upper main body by setting a rainwater trough on the outer wall, so as to realize the interspersed construction of the outer wall.

150 mm high cement brick backwalls shall be built around the tower cranes, equipment hoisting openings and skylights, and the fullness of mortar shall be greater than 90%, Ensure the water closing effect.

The water interception and drainage part in the wet operation area (1) the water interception and drainage of the hydropower well adopts the formwork with the same size as the opening along the inverted sill surface of the structure, fixed with nails, and find a 3% slope outward.

Temporary water points on the floor of the drainage part of the dry operation area: the construction water riser is buried in the shear wall of the staircase, 1000 * 600 * 150mm lime sand brick back sill is built at the construction water point on each floor, and 100mm PVC vertical guide pipe is installed to guide the flow layer by layer.

(2) Water cut-off seal of air shaft and reserved hole through floor (water cut-off and sealing in wet operation area) A.

(3) According to the principle of full interspersed system, the water and electricity installation has been inserted, the permanent drainage under the balcony and toilet has been installed, and the processes of backfilling, leveling and waterproof shall be completed according to the requirements of the drawing.

b.

Detailed practice of aboveground water interception 1.

b.

The drainage pipe is led out of the room along the shaft, and the drainage pipe is raised with the water interception floor.

3.

Introduction to the general practice of water interception system, the floor is divided into two areas: dry operation area and wet operation area; “Dry operation area” refers to the construction area below the intercepting layer, and only temporary water points are subject to diversion treatment; “Wet operation area” refers to the construction area above the water cut-off layer.

The PVC pipe is divided into two to drain the water to the nearest water collection point and drain it to the outside through the temporary drainage pipe installed in the elevator shaft.

2.

Ensure the normal operation of each process of interspersed construction, and avoid pollution or damage to other processes due to improper management of floor construction water.

2.

No.4 summary (including preventive measures) full interspersed construction technology is the main construction method to speed up the construction period and improve work efficiency for the project.

Drainage system: external walls, toilets, balconies, elevator shafts, water and electricity wells, stairs and floor water points.

The rain gutter moves upward with the progress of the main body inside the climbing frame.

The water cut-off of the floor can be inserted into the facade and indoor in advance, and each process is full interleaved construction, so as to ensure the normal operation of each process of interleaved construction and realize the full interleaved construction technology..

Rapid construction system – Summary of No.1 case of floor water interception construction technology to ensure that all processes in the full interspersed system can be inserted in time and that all processes with no water operation interface must be provided in the floor and basement can be carried out smoothly.

Blocking parts of water interception in wet operation area (1) blocking of formwork transfer hole, setting out hole, flue and air shaft hole A.

(the joints between the aluminum plate and the structure shall be installed tightly, and the joints that are too large shall be sealed with glue.

(5) Water interception and drainage of the external wall A.

The formwork shall “buckle” the inverted sill, and the surface shall be painted with red and white paint.

detailed practice of water interception in the basement 1.

The water interception and drainage part of wet operation area (1) water interception and drainage of hydropower well (the same as the water interception and drainage method of aboveground hydropower well) (2) the water interception and drainage of toilet is the same as the principle of full interspersed system.

The reinforcement of precast cover plate is the same as that of floor slab.

II.

(2) The hole of the pump pipe is blocked, and the formwork is processed along the reserved hole size of the concrete pump pipe.

On the first floor of the climbing frame, a 150mm * 100mm * 1mm galvanized aluminum sheet intercepting tank is continuously arranged along the outer wall, with a slope of 1%, fixed with self tapping screws, and a drainage pipe is installed at the lowest point, which is drained to the nearest drainage point and discharged through the permanent drainage pipe of the floor.

Water intercepting system in wet operation area A.

reserve 50 mm wide and 2 / 3 plate thickness groove around each reserved hole, embed the finished reinforced concrete cover plate and fill the joint with ointment.

b.

100mm high lime sand brick inverted sill shall be built around the setting out opening, and the upper part shall be covered with formwork.

1.