The shear wall formwork adopts C-shaped steel keel to replace the traditional formwork system, which greatly reduces the number of main keels.

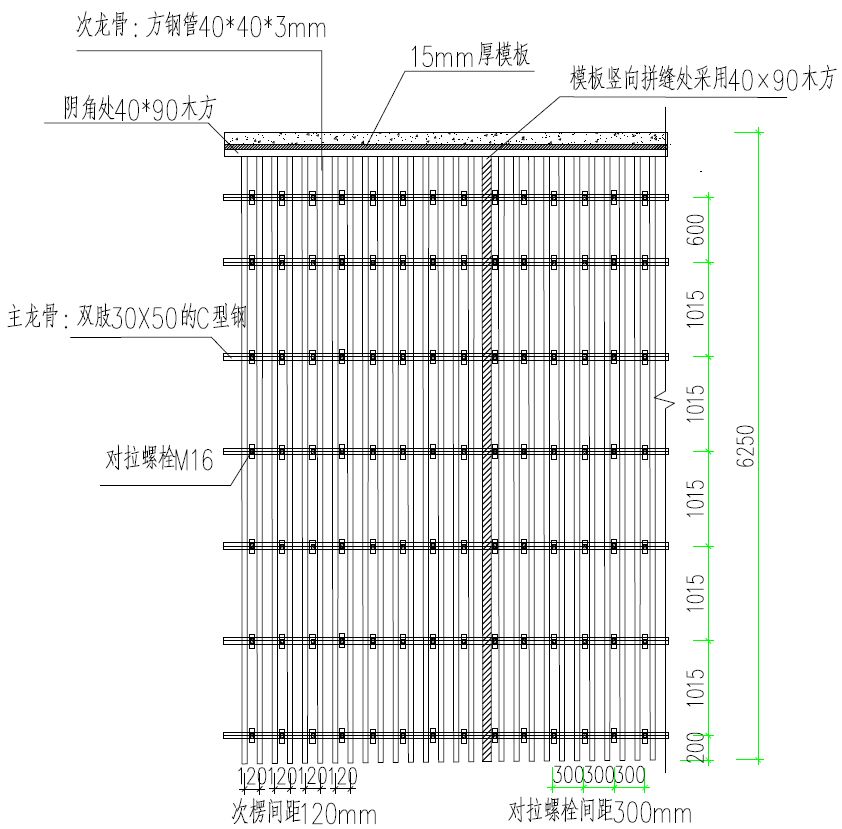

Screw hole spacing (horizontal): the horizontal spacing of the bottom three courses is 200mm, the other horizontal spacing is 300mm, and local positions such as corners can be set separately.

Split bolt 7) PVC sleeve: the length is equal to the wall thickness, a bell mouth is set at both ends, a sleeve is set at each split bolt, and the split bolt is passed through the sleeve to replace the cement lining rod.

The whole formwork is connected with 100mm lath, and the split screw hole is set in the lath to avoid opening of the whole formwork.

On the premise of meeting the wall thickness and stress requirements of section steel, the main keel system achieves the purpose of reducing weight.

4) Reinforcement treatment of external corner square steel: the lock is composed of lock pin, C-type lock and reinforced jacking wire, which is used for the reinforcement of external corner of shear wall.

It has the advantages of light use, simple operation and many turnover times, and greatly reduces the labor intensity of workers.

Example of construction effect of C-shaped steel keel formwork hole free system formwork system component 1) main and secondary keels: 60mm * 60MM “C” cold-rolled steel strip is adopted, with wall thickness of 2.75mm, weight of 4kg / m, section resistance moment w = 20.80cm3 and section inertia moment I = 52.00cm4; Vertical secondary keel: it is cut from Q235 40 * 40 * 3 square steel, with a single 6000mm high square steel and a spacing of no more than 120mm.

40 * 40 * 3 small square steel is used for the vertical secondary ridge, with a spacing of 120mm; 40 * 90 wood square joint is adopted at the vertical joint between formwork.

Height of wall formwork (from bottom to top): 250mm, 915mm, 100mm, 915mm, 100mm, 915mm, 100mm, 915mm, 100mm, 915mm, 845mm.

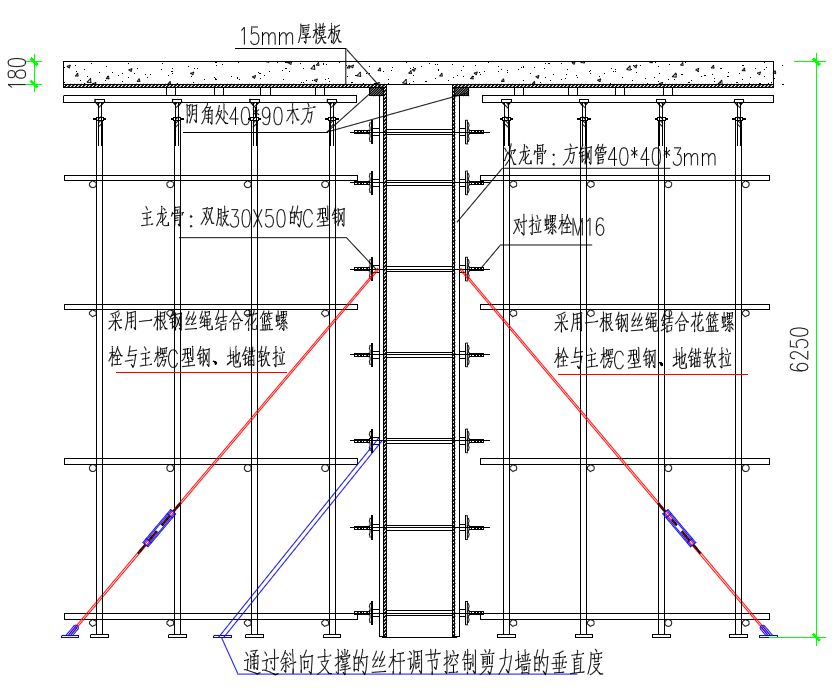

Preparation of special construction scheme for oblique support construction process → technical and safety disclosure → welding of wall root positioning reinforcement → setting of angle iron anti rotten root → formwork preparation according to formwork turnover drawing → closing one side formwork → threading PVC casing and split bolt → closing the other side formwork → installing vertical secondary keel → installing horizontal main keel → installing split bolt gasket → fastening split bolt nut → verticality correction Fixing of front and diagonal bracing → three inspections (self inspection, mutual inspection and special inspection) → reporting to the supervisor for acceptance.

Connect the split screw with square steel with special gasket to support and stabilize together.

Schematic diagram of seven screw formwork of 6.25m shear wall in basement (plate thickness 180mm).

The screw hole is set on the plate strip or non whole formwork, which realizes the whole formwork without opening, which is worthy of reference and application.

Schematic diagram of the front elevation of the seven bolts of the 6.25m shear wall in the basement (plate thickness 180mm) schematic diagram of the section of the seven bolts of the 6.25m shear wall in the basement (plate thickness 180mm) key points of operation 1) prepare the formwork and drill the screw holes according to the design scheme.

A casing is set at each split bolt, and the split bolt is passed through the casing to replace the cement lining rod.

Small parts, template assembly, tighten the lock according to the construction process.

The transverse main ridge adopts 7-way double leg 30X50 C-shaped steel, and the length is according to the wall configuration requirements.

5) Cross bar connector: it is composed of a square steel pipe and two locking pins.

Advantages of internal angle square steel: it can ensure that the internal angle of shear wall is formed square, which can be used with the wall cross bar, with fast connection and simple operation.

The split bolt adopts M16 split screw with a spacing of 300, and is reinforced with double nuts.

3) The utility model is composed of a shear hook and a transverse bolt, which are used for reinforcing the opening.

The cross bar connector has good rigidity and stability, bears the lateral pressure and self gravity in concrete pouring, has large load strength, and has no construction problems such as formwork running, formwork expansion and slurry leakage.

The screw holes must be set on the plate strip and non full formwork, and ensure the correct shape and size of each part of the structure and components..

The formwork adopts 15mm thick covered plywood.

Fixing Socket Angular End Nail Plate

From the Qidong maternal and child health hospital project undertaken by Nantong second construction group, the shear wall in the basement of the podium building of the outpatient complex building is 6.25m high, the wall thickness is 350mm, and the thickness of the first floor structural plate is 180mm.

PVC casing 8) diagonal support: through the adjustment of screw rod, it can pull and top, so as to better control the verticality of shear wall.

The top plate formwork is pressed on the wall formwork, and the lower opening of the root formwork is 15mm away from the ground.

2) Square steel for internal corner: the internal corner of the new shear wall formwork is supported by a horizontal bar superimposed with an L-shaped bar to form an internal corner reinforcement system to ensure that the internal angle is 90 degrees.

Through calculation, it can be obtained that the height of wall formwork configuration H = 6250 (height) – 180 (plate thickness) – 15 (roof formwork thickness) – 15 (lower opening elevation) = 6040mm.

The length of PVC casing is equal to the wall thickness, and a bell mouth is set at both ends.

Advantages of reinforcement: one pin and one top can quickly complete the external corner reinforcement, effectively avoid the problem of loosening and deformation in the external corner reinforcement of traditional shear wall, and ensure that the external corner of shear wall is square and free of slurry leakage.

Advantages of opening lock: two hook bolts are used to hook the positioning hole on the cross bar to quickly tighten the short cross bar.

The perpendicularity of the opening can be adjusted by tightening the bolts, which can quickly complete the reinforcement of the opening formwork.

6) Split bolt: adopt grade a M16 screw (grade 5.6 split bolt, design value of tensile strength = 205n / mm2).

The screw hole spacing (vertical) is 200mm, 1015mm, 1015mm, 1015mm, 1015mm, 1015mm and 600mm respectively.

The new shear wall support is made of steel, which saves materials and costs.

The formwork is configured for the basement of the podium building of the complex building, with a wall height of 6.25m, a wall thickness of 350mm and a plate thickness of 180mm; The lower part of the formwork adopts 50 * 50 * 4 angle steel for positioning and root rot prevention measures.