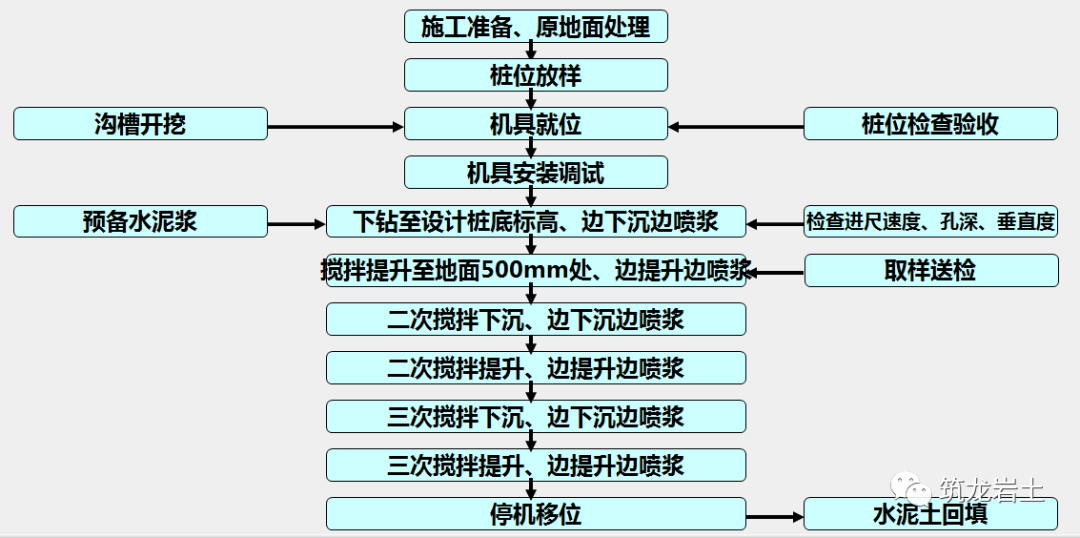

The construction of cement mixing pile shall adopt the mixing process of three times up and down of the mixing head.

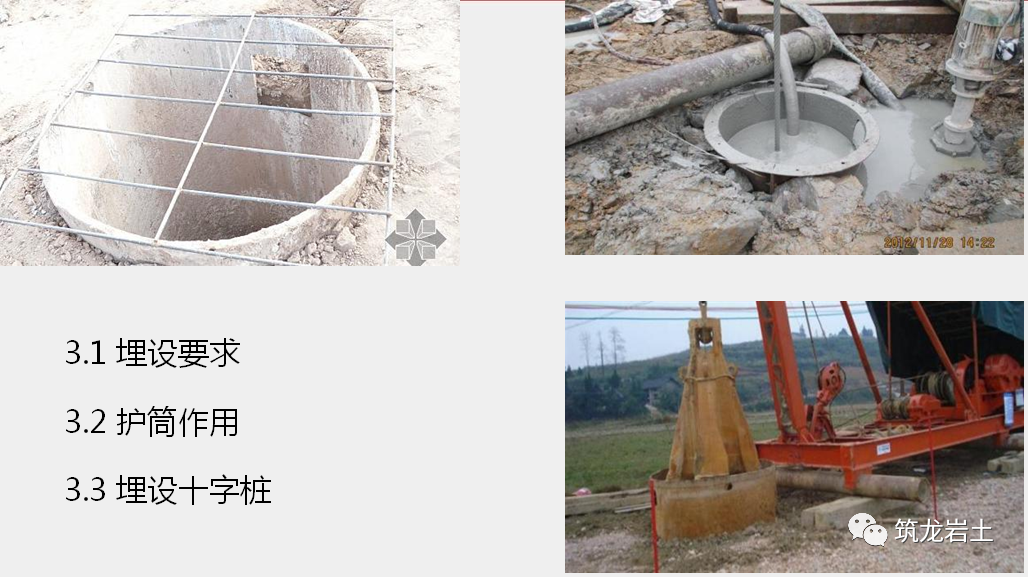

In order to prevent the uplift of cement soil during the construction of cement mixing pile from affecting the construction, the construction groove shall be excavated according to the contour line of cement soil mixing pile on site, and the depth of the groove shall be determined according to the amplitude and length of the pile.

Case: the design requirements of cement mixing pile of Wenzhou Guoxi project 1.

The foundation pit excavation can only be carried out when the strength of cement mixing piles reaches the age of at least 28 days.

Before the operation of pile machine, the on-site supervisor and Party A shall check whether the mixing pile machine reaches the operation position.

There is a digital display screen in the control room to display the weight of water and cement added each time (see Figure 1 below).

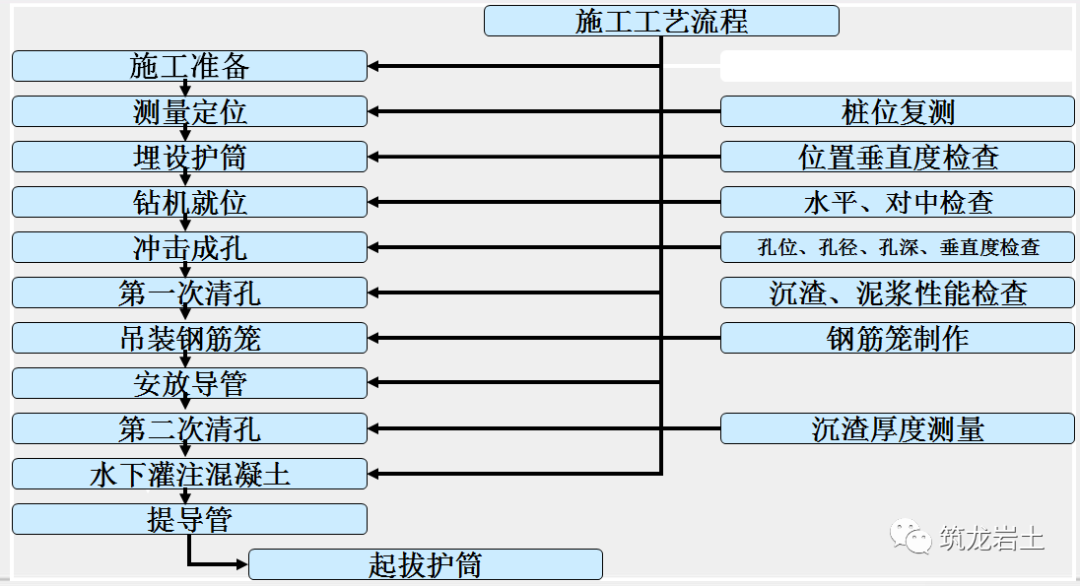

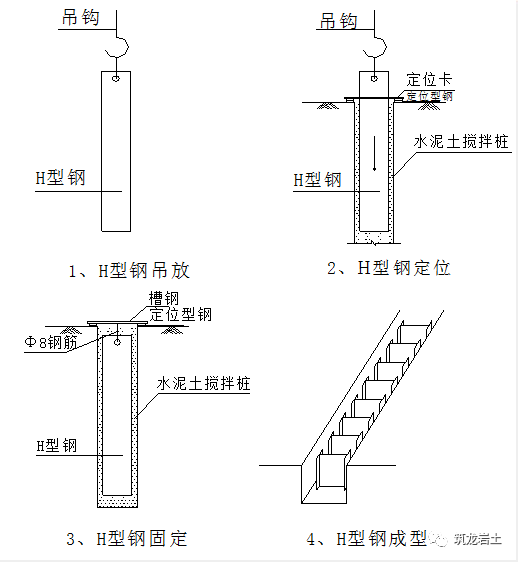

construction process flow of cement mixing pile construction flow chart of cement mixing pile 1.1 construction preparation 1.

5.

When the mixing head sinks to the design depth, the verticality of the machine shall be checked and adjusted again.

5.

The compressive strength of single shaft of cement mixing pile shall meet the design requirements of 28d.

6.

The foundation pit excavation can only be carried out when the strength of cement mixing pile reaches the age of at least 28 days.

4.

Construction drawing preparation: be familiar with and master the design and construction drawings, fully understand the design intention, and communicate with the design unit in time in case of any doubt.

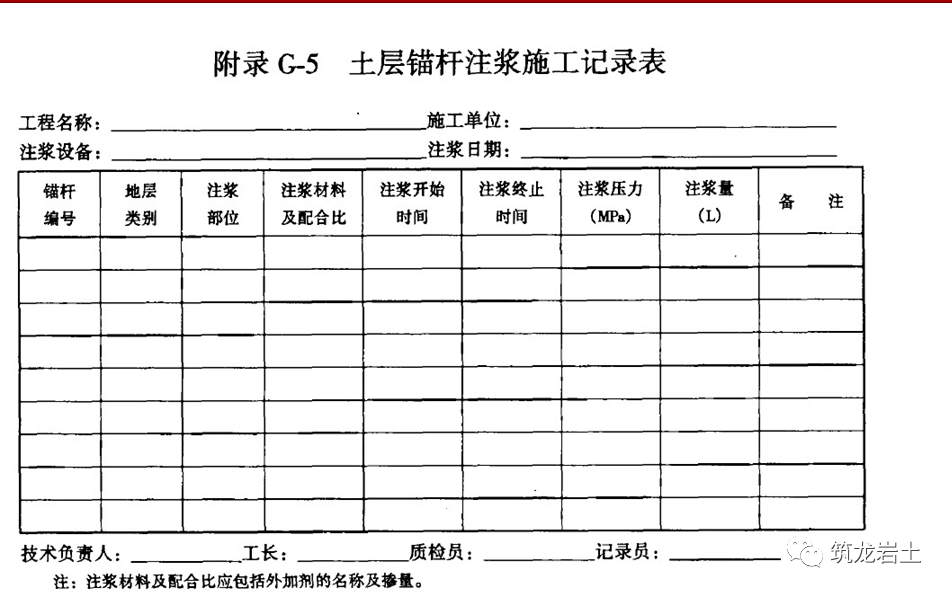

The cement mixing pile adopts 42.5 ordinary portland cement, the cement content in the active area is 15%, the cement content in the passive area is 15%, the water cement ratio of cement slurry is 0.45, and 0.05% triethanolamine and 0.2% lignin are added; 2.

4.

If it does not meet the design requirements, the construction technology shall be adjusted in time.

Generally, the slurry is mixed on site.

3.

7.

After moving, check the positioning situation.

1.6 mixing into piles 1.

For cement mixing pile, excavation inspection shall be carried out within one week after construction or pile quality shall be checked by means of drilling and coring.

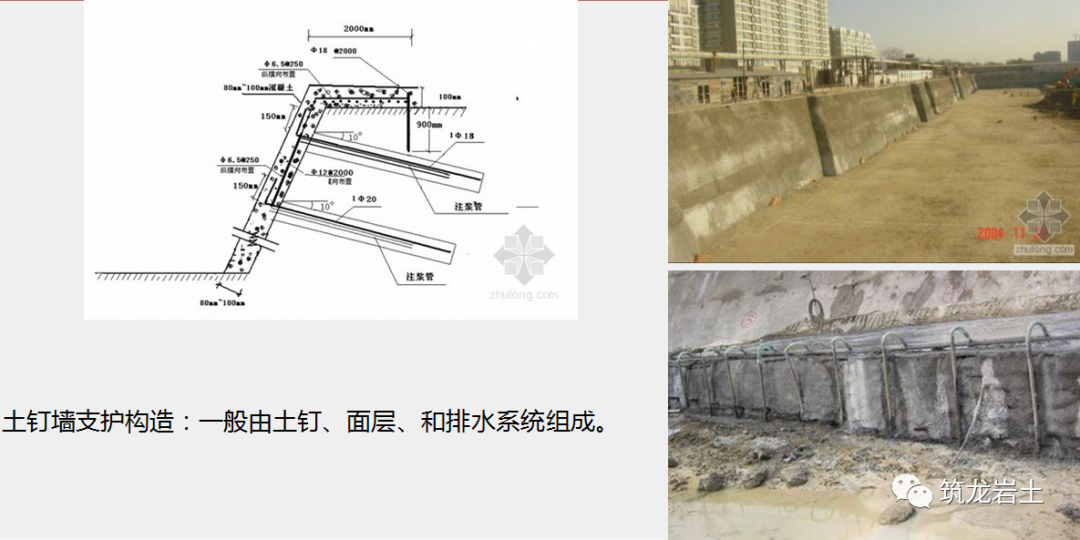

Early stage management flow chart of housing construction deep foundation pit project I.

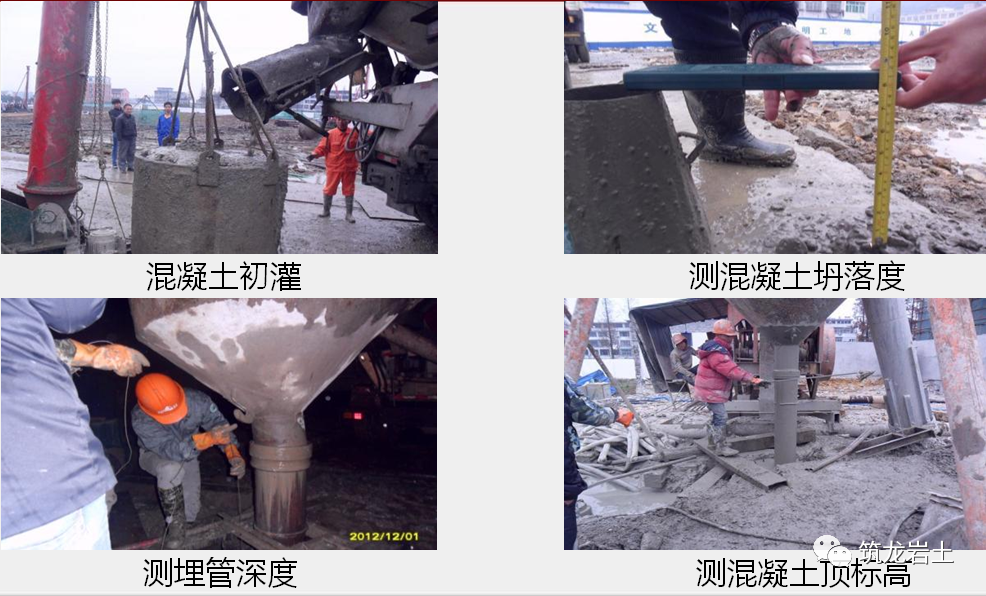

2) When mixing, first add water, then add cement according to the mix proportion of the laboratory and put it into the mixer (see Figure 2 below).

Before excavation, the pile quality shall be tested by core drilling method.

4.

4.

1.3 trench excavation 1.

On the positioning control line of piles, pile position marks shall be set every 5m to ensure that the overlapping between piles meets the specifications and design regulations.

The steel plate and road base plate shall be paved under the pile driver.

Before construction, the ponding in the trench must be removed to prevent the ponding from infiltrating and affecting the pile strength of cement soil mixing pile.

The cement used for cement mixing pile, cement content in active area, cement content in passive area, water cement ratio of cement slurry and admixture shall meet the requirements of design and specifications.

The number of core drilling shall not be less than 2% of the total number of piles and shall not be less than 5.

The uniaxial compressive strength of cement mixing pile at the age of 28 days shall not be less than 1.0MPa, and five groups of tests shall be conducted, with no less than three pieces in each group.

When the cement mixing pile machinery is in place, the maximum deviation shall not be greater than 2cm, and the verticality of the leveling machinery shall not be greater than 1% of the pile length.

1.2 setting out of pile position before setting out of pile position, the traverse points and benchmarks handed over by the planning and surveying unit shall be rechecked and used after confirmation.

2.

3.

The pile driver shall be in place stably and straightly.

3.

In the process of trench excavation, the construction unit is required to have a special person responsible for on-site guidance.

Before construction, it shall be reported to Party A and the supervising engineer for review, and fill in the survey and setting out inspection form, which shall be reviewed and signed by Party A and the supervising engineer.

3.

When the cement mixing pile machinery is in place, the deviation and verticality of the machinery shall meet the design and specification requirements.

1.4 the pile driver shall be in place under the unified command of the construction worker and the pile driver team leader.

Source: the copyright of Greentown group belongs to the original author.

The surveyor shall carry out the survey and setting out work related to the mixing pile position, original ground elevation and orifice elevation according to the design and construction drawings, and make the survey and setting out records and pile layout drawings.

2.

5.

Preparing cement slurry and slurry 1) for each batch of cement entering the construction site, the supervisor, Party A and the construction unit shall jointly weigh the cement tank truck to ensure the double control of the weight of cement entering the site.

5) The supervisor and Party A shall supervise the whole process during the backstage construction..

Observe with theodolite or plumb hammer to ensure the verticality of the drilling rig.

If there is any deviation, it shall be corrected in time, and the deviation of the pile position shall not be greater than 50mm.

3) Put it into the cement slurry storage tank after full mixing (see Figure 3 below); 4) The cement used for the cement mixing pile, the cement content in the active area, the cement content in the passive area, the water cement ratio of the cement slurry and the admixture shall meet the design and specification requirements.

The weight ratio method is used to control the mixing of cement slurry, and computer batching is used.

According to the construction plan of cement soil mixing pile, the positioning control line of pile shall be set at the edge of the trench.

2.

Scheme preparation: prepare relevant construction schemes and submit them to the owner and the supervisor for approval before implementation.

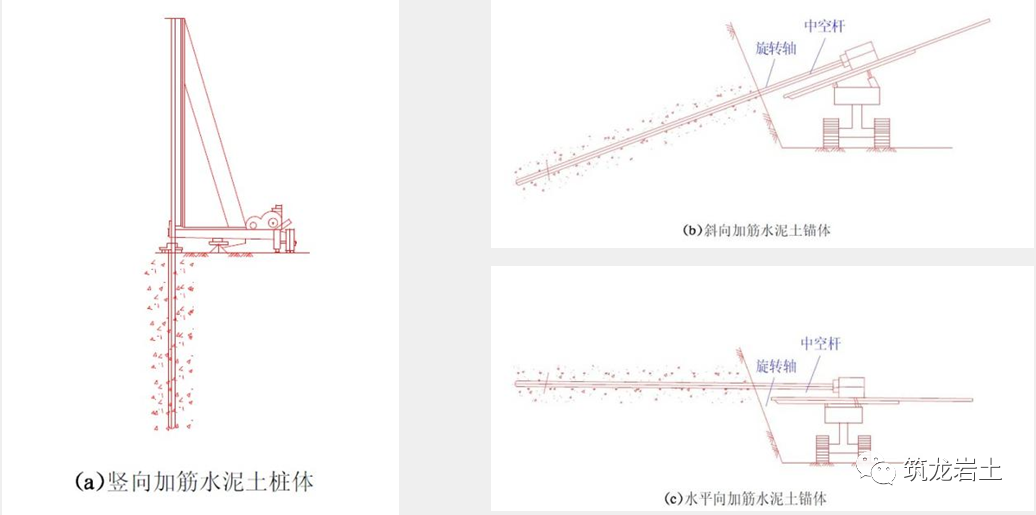

1.5 requirements for design parameters of cement mixing 1.

According to the construction experience in Wenzhou, the lifting (or sinking) speed during spraying is 0.8 ~ 1.0m/min.

According to the construction drawing, the construction outline of cement mixing pile shall be measured on site as the boundary of trench excavation.

Before moving, see the situation of the front, rear, left and right positions.

Site preparation, survey preparation, pile test, etc.

5.

If any obstacle is found, it shall be removed in time.

Test preparation: raw materials shall be sampled and submitted for inspection as required, and put into use after passing the retest.

Before excavation, the pile quality shall be tested by core drilling method, and the number of cores shall meet the requirements of design and specifications.

The construction mixing times, lifting (or sinking) speed during spraying and pumping pressure of cement mixing pile shall meet the requirements of design and specifications.

Disclosure preparation: hold a meeting of all personnel of the project department to make construction technology and safety technology disclosure to the construction personnel and operators, so that the employees can understand the design intention, master the construction essentials, key processes and safety operation procedures, and achieve clear division of labor and clear responsibilities.

When the mixing head sinks to the design depth, the verticality of the machine shall be checked and adjusted again.

The verticality accuracy of mixing pile shall not be less than 1 / 200.

The pumping pressure of cement mixing pile is 0.3MPa, and the pumping flow shall be constant.